301ENGINE

-

WORK

ON

THE

INDIVIDUAL

PARTS

134

400373-10

I

Cbecklnl

the

rocker

arm

sbafts

~

30111g..10

Installinl

the

valvl'

200188-10

200187-10

- Check the sealing

area

of the cylinder for distortion using a straight

edge

and the

special tool.

I Feeler gauge

(59029041100)

(

..

p.

256)

Cylinder/cylinder head - sealing

area

distortion

s 0.1

mm

(S

0.004

in)

>

If

the measured value does not equal the specified value:

- Change the cylinder head.

- Check sealing

seat.

of the valves.

Valve

Intake sealing seat width

I

2.00

mm

(0.0787

in)

Valve

Exhaust sealing seat width

I

2.00

mm

(0.0787

in)

>

If

the measured value does not equal the specified value:

- Machine the valve seat.

-

Blowout

all oil holes with compressed air and check that they are clear.

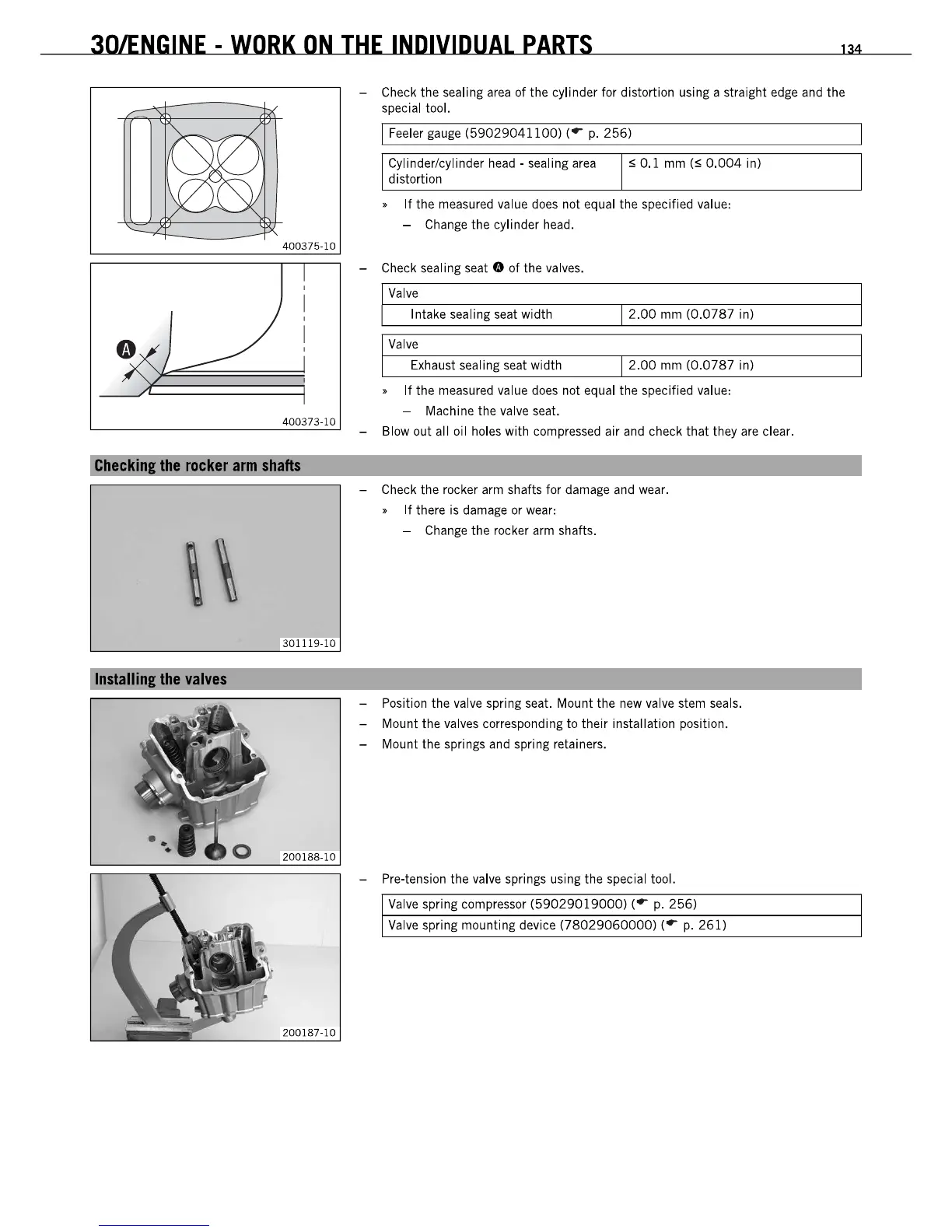

- Check the rocker arm shafls for damage and wear.

>

If

there is damage or wear:

- Change the rocker

arm

shafts.

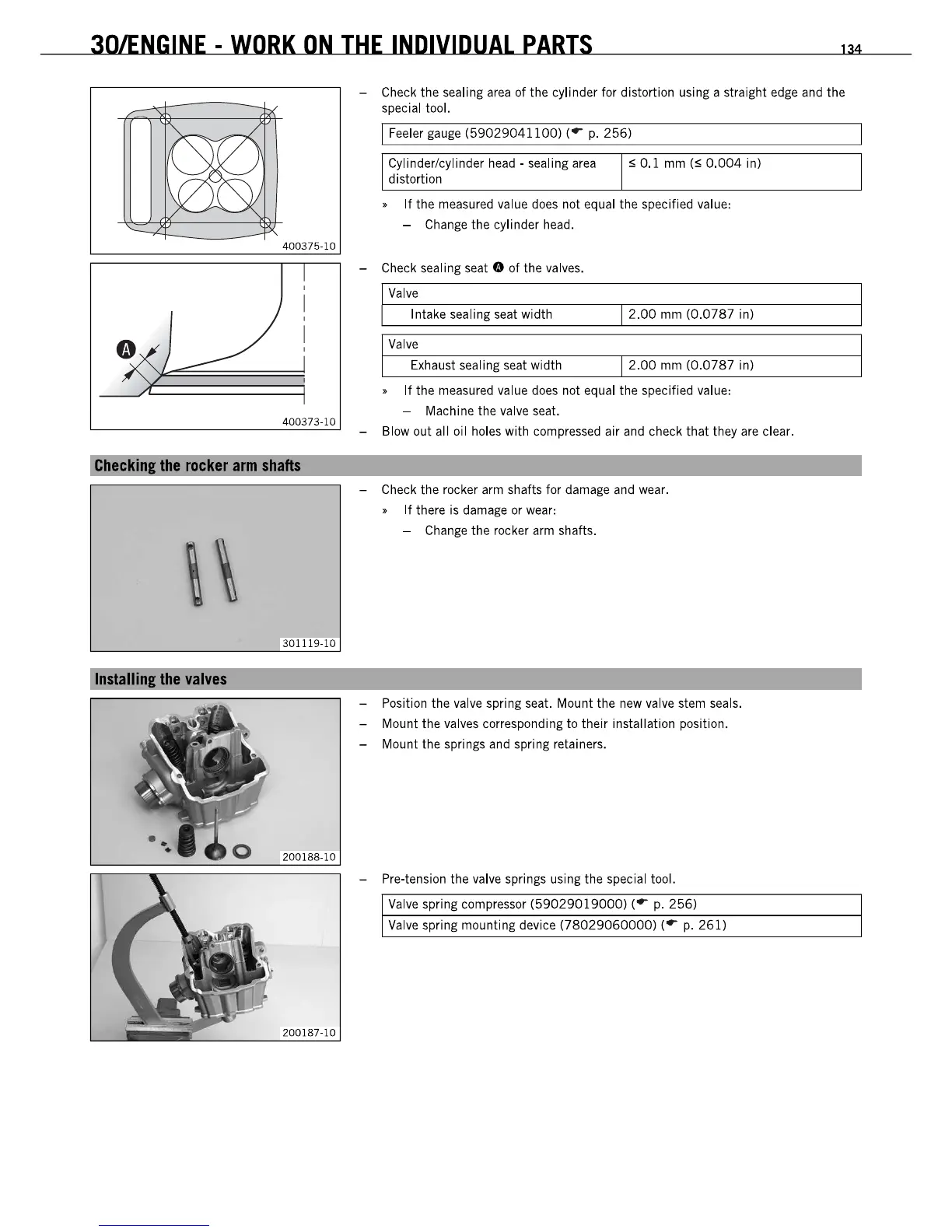

- Position the valve spring seat. Mount the

new

valve stem seals.

- Mount the valves corresponding to their installation position.

- Mount the springs and spring retainers.

- Pre-tension the valve springs using the special tool.

Valve spring compressor

(59029019000)

(

..

p.

256)

Valve spring mounting device

(78029060000)

(

..

p.

261)

1

301ENGINE

-

WORK

ON

THE

INDIVIDUAL

PARTS

134

400373-10

I

Cbecklnl

the

rocker

arm

sbafts

~

30111g..10

Installinl

the

valvl'

200188-10

200187-10

- Check the sealing

area

of the cylinder for distortion using a straight

edge

and the

special tool.

I Feeler gauge

(59029041100)

(

..

p.

256)

Cylinder/cylinder head - sealing

area

distortion

s 0.1

mm

(S

0.004

in)

>

If

the measured value does not equal the specified value:

- Change the cylinder head.

- Check sealing

seat.

of the valves.

Valve

Intake sealing seat width

I

2.00

mm

(0.0787

in)

Valve

Exhaust sealing seat width

I

2.00

mm

(0.0787

in)

>

If

the measured value does not equal the specified value:

- Machine the valve seat.

-

Blowout

all oil holes with compressed air and check that they are clear.

- Check the rocker arm shafls for damage and wear.

>

If

there is damage or wear:

- Change the rocker

arm

shafts.

- Position the valve spring seat. Mount the

new

valve stem seals.

- Mount the valves corresponding to their installation position.

- Mount the springs and spring retainers.

- Pre-tension the valve springs using the special tool.

Valve spring compressor

(59029019000)

(

..

p.

256)

Valve spring mounting device

(78029060000)

(

..

p.

261)

1

Loading...

Loading...