Page 8 of 12 TP1B001–1 English

Jun 2013

12

How To Use Dynamic Message

Orientation

Linx 5900

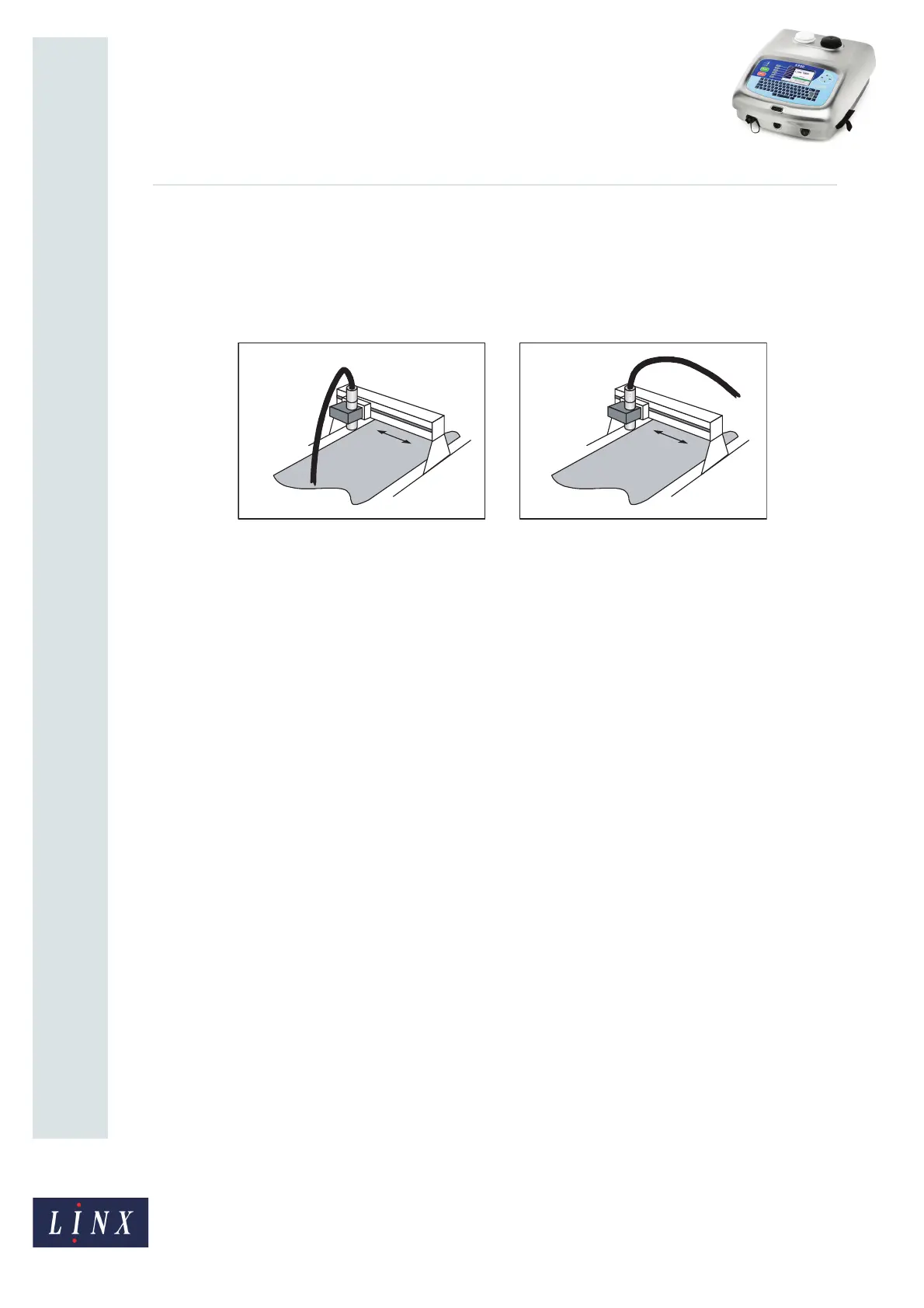

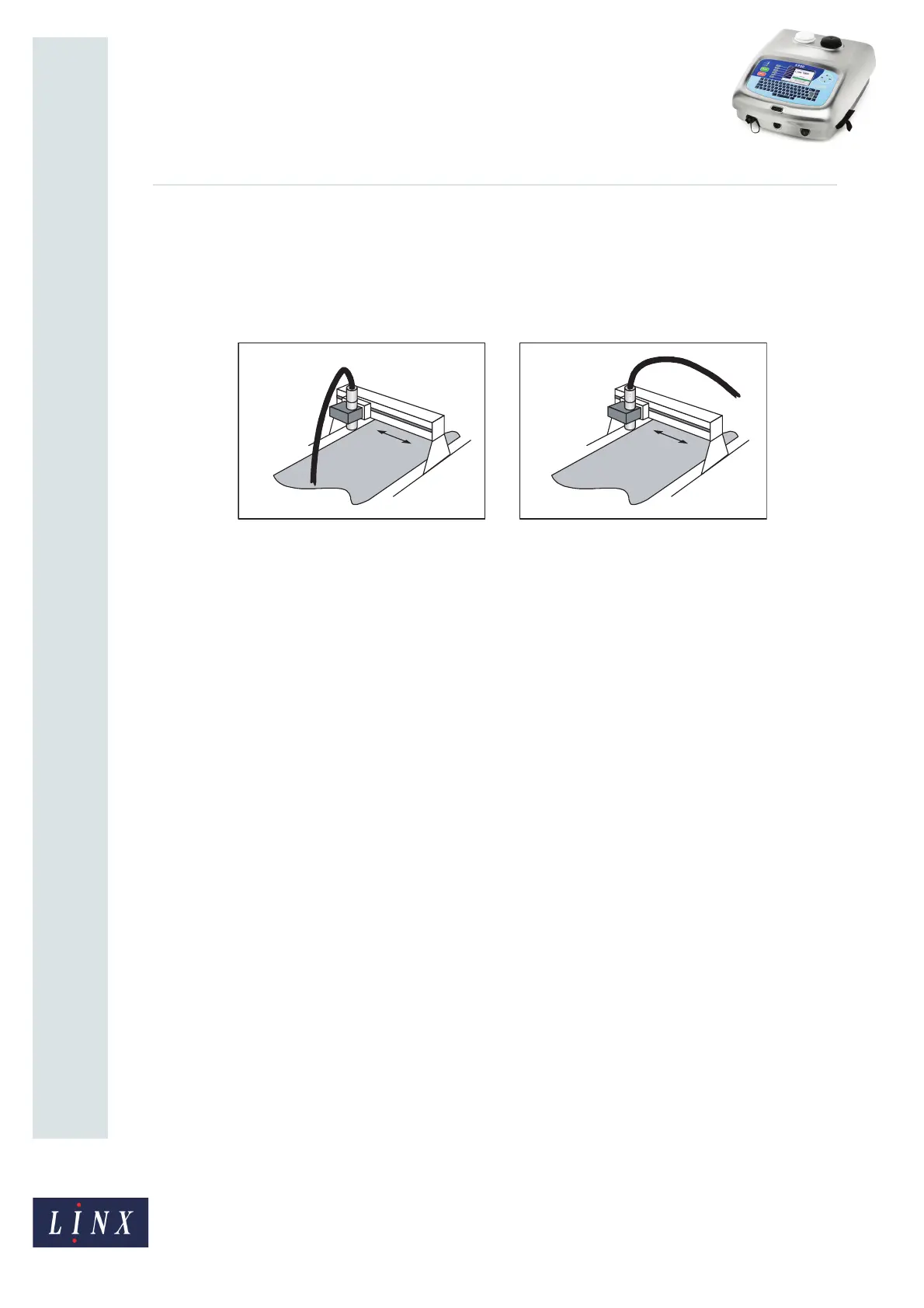

• Make sure that the printhead movement does not apply a rotation force (torsion) to the

conduit clamp at the printhead end of the conduit. Figure 7 (a) shows an incorrect

design that causes this problem. The rotation force is reversed when the printhead

direction is reversed. These repeated reversals can cause a failure of the conduit at the

printhead end. Figure 7 (b) shows a better design that causes only a bend in the

conduit, but does not cause any torsion.

Figure 7. Conduit tension

NOTE: Remember to allow access to clean the printhead.

2.2.4 Printhead vibration

Make sure that the printhead mounting minimizes any vibration from the traversing arm. If

there is any vibration, the path of the ink drops can change. Any high-frequency vibrations

(including very small vibrations), cause a larger effect than a low-frequency vibration. The

effect is proportional to the square of the frequency.

A vibration can cause the following problems:

• The print quality decreases.

• A gutter failure occurs.

Print quality

The print quality decreases because the vibration changes the ink drop positions on the

substrate. This problem is likely to occur before a gutter failure occurs. (the effect depends

on many factors, so no numerical limits can be defined.)

Gutter failure

A stronger vibration can cause a gutter failure. This problem occurs if a large number of ink

drops hit the edge of the gutter, and are not collected by the gutter.

A vibration, or a sudden start or stop, is a sudden increase or decrease in the speed of the

printhead movement (that is, an acceleration). To prevent a gutter failure, you must make

sure that the acceleration of the printhead is not too high.

Loading...

Loading...