172Service Manual – SC5000 30 - Solution System

Solution Level Indication is not Correct

The solution level sensor is comprised of 3 independent sensor bodies working together. This is important to

understand for the purposes of troubleshooting, because one sensor can fail and not affect the other 2. This

could give unexpected results on a machine, such as displaying less uid than what is actually in the tank,

but no error is detected.

For example, if the bottom sensor were to fail, the MMC would

report that the tank was empty until the 2nd sensor detected

uid, and even then, it would report that the tank was only

1/3 full. Then when the 3rd sensor was active, the MMC would

report that the tank was only 2/3 full, when it is actually full.

Testing individual sensor bodies

Because the capacitive sensing technology is also used for

touch-sense circuits, the easiest method for manually activating

a sensor body is to use the capacitive nature of your own hand.

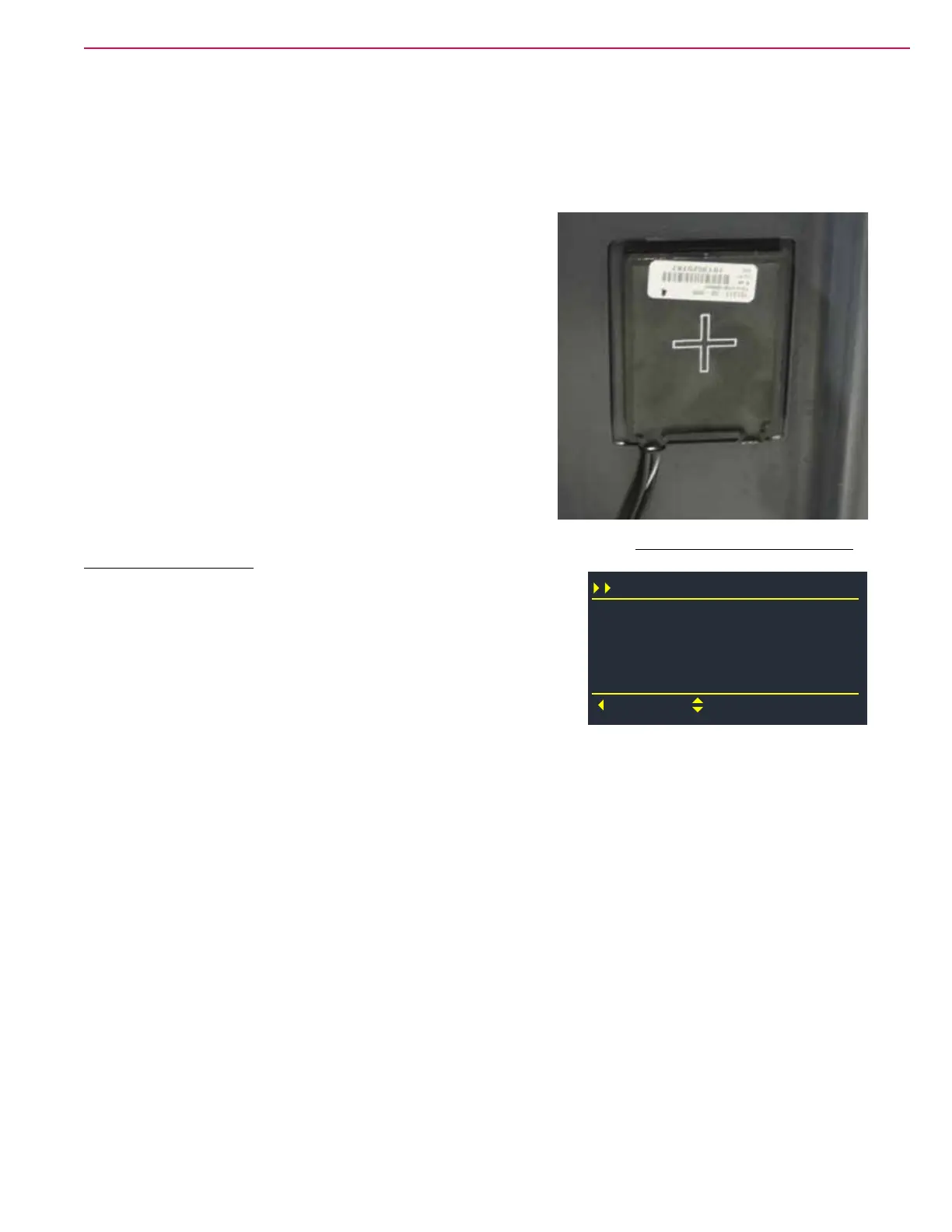

The crosshair on the back of the sensor body represents the

location of the sensing element, and if you simply place your

ngers over the crosshair, you can see the display value on the

Service menu change to indicate that the sensor is active.

In the event that you cannot safely put your hand over the

sensor, you can also use a piece of conductive metal, such as a

stainless steel ruler, a piece of wire, a screwdriver, or even a piece of tin foil; as long as you hold one end of

the metal in your hand.

When you activate or deactivate a sensor body, keep in mind that

the Controller intentionally slows down the change in voltage across

the sensing resistor to avoid sloshing water from causing misleading

results. So it may take several seconds for the value to completely

change from one state to another.

Symptom: The controller indicates the tank is not full when the

tank is actually full. (The Service Menu displays less than 0.55V or

5.5 mA)

• One or more of the sensor bodies is not functioning, so the entire assembly must be replaced. Because

the replacement procedure requires the recovery tank to be removed, drain both the recovery and

solution tanks, remove the recovery tank, and conrm the diagnosis by testing each sensor manually

• If all 3 sensor bodies appear to be functioning with manual activation, the most likely cause is corrosion

in the electrical connector(s) causing a reduction in current ow.

Symptom: The controller reports the tank is empty when it is full. (The Service Menu displays zero volts/

amps).

1. Disconnect the J2 connector from the Controller, and check for a short between J2-3 and Chassis ground

(not J2-9).

• A short between J2-3 and J2-9 is not suspected, because the controller would be reporting amperage

ow and/or an error.

• If a short is detected, repair/replace the harness between the Controller and X190.

• Otherwise, continue.

2. Reconnect J2 and power the machine. Check the voltage between J2-3 and J2-9 for 5 volts.

• If 5 volts is not present, replace the controller.

• Note that a short circuit was already eliminated as a possible cause.

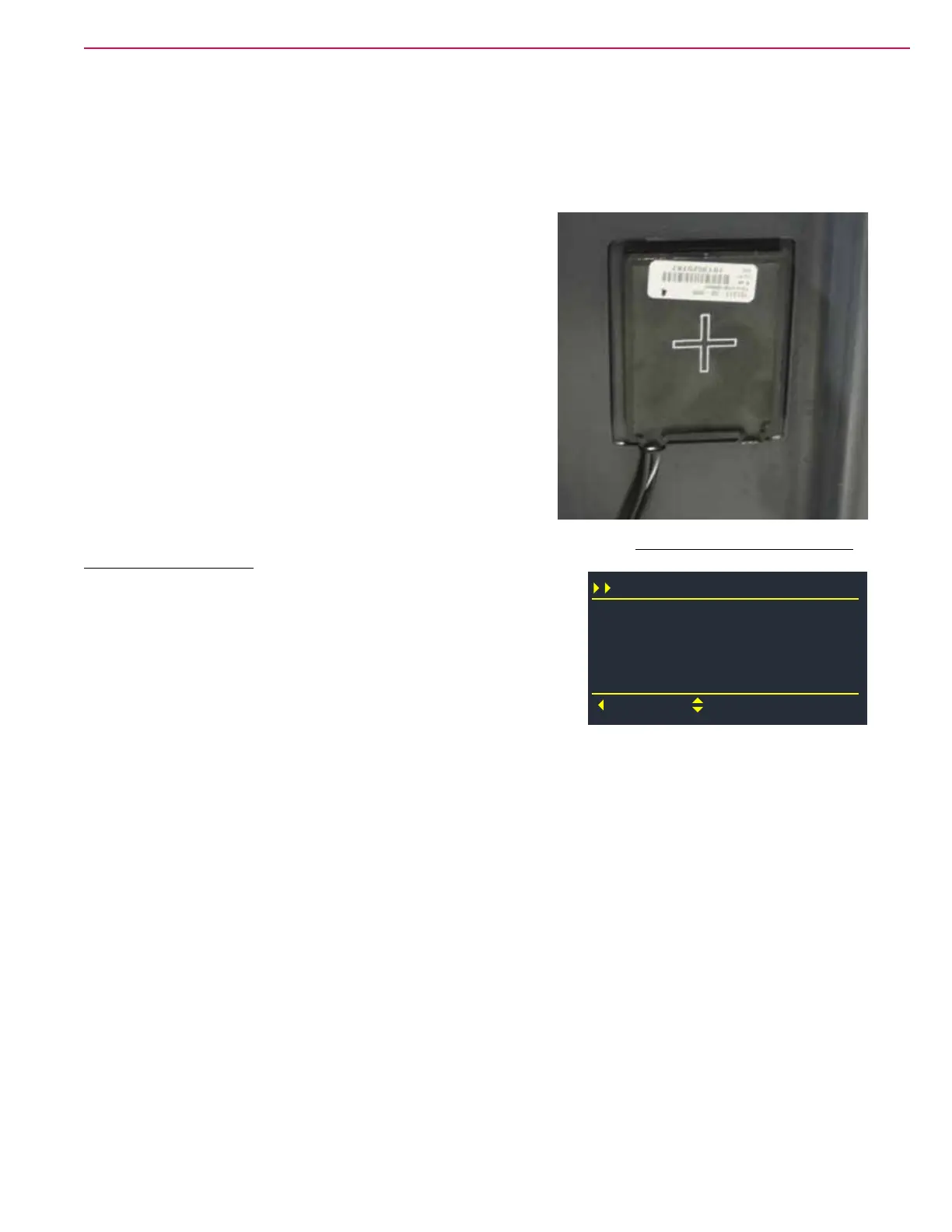

A1 Main Controller

J2-3 SOLUTION LEVEL

Back

Scroll

J1-14 SOLUTION SOL

M24 DETERGENT PUMP

0.44

Off

Off

Loading...

Loading...