97Service Manual – SC5000 20 - Drive System

Drive Tire

DELETE???

The drive tire consists of the urethane tire and the metal rim that it is attached to. The drive tire may be

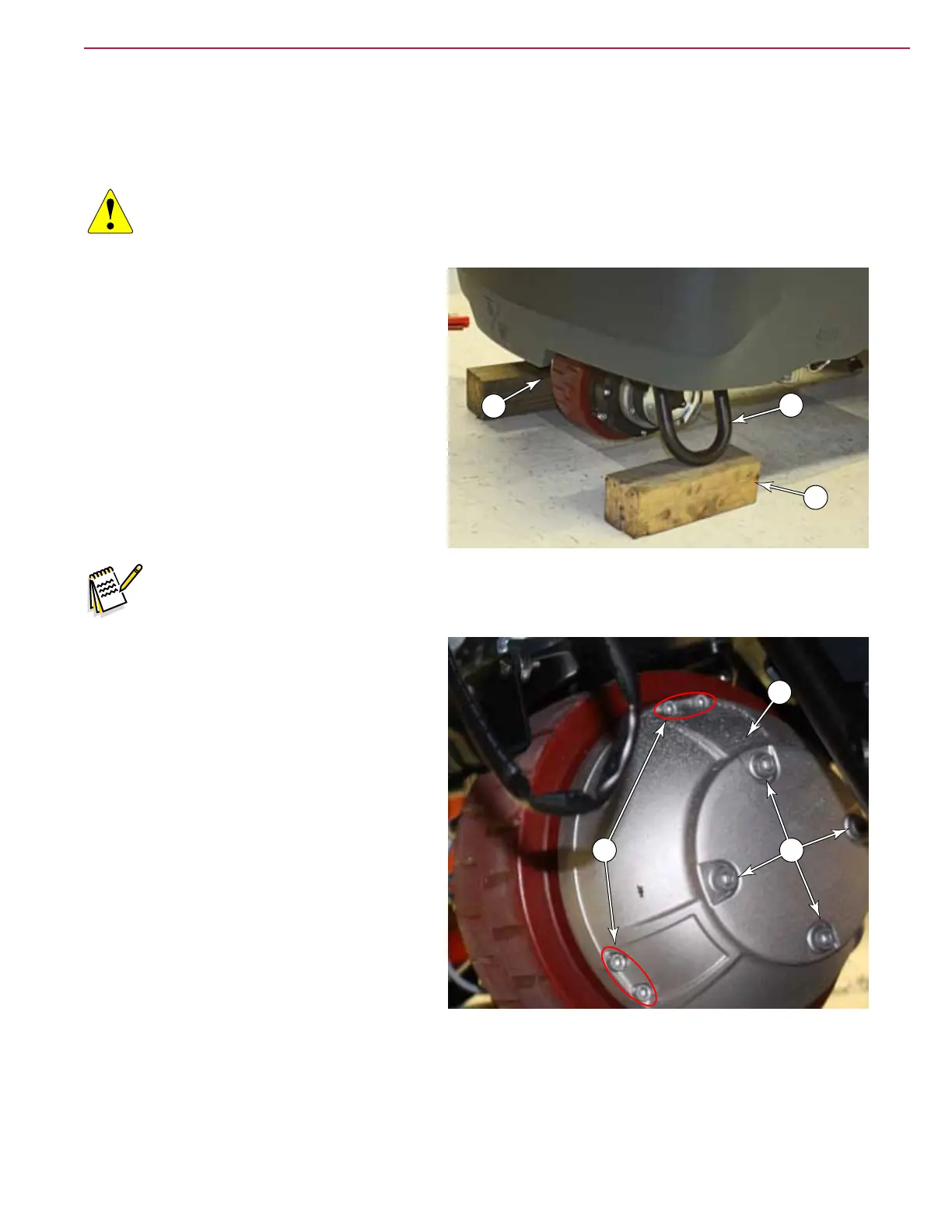

replaced without removing the wheel motor assembly from the machine. Pressing the rim off the wheel

motor requires the tire pulling kit (56422174).

WARNING: This procedure requires working on an elevated machine. Make sure all safety

precautions are in place before beginning this procedure. Use appropriate lifting

points, jack stands, and wheel chocks. Make sure to disconnect the main battery

connector under the operator’s seat.

1. To reduce the weight of the machine, drain

both the recovery and solution tanks.

2. Chock both rear wheels to prevent the

machine from moving. Once the front wheel

is off the ground, there will be no machine

brake.

3. Disconnect the main battery connector under

the operator’s seat.

4. Lift the machine at the lifting point (A) until

the drive wheel is slightly off the ground,

and then place blocks (C) under the anti-tip

hoops (B).

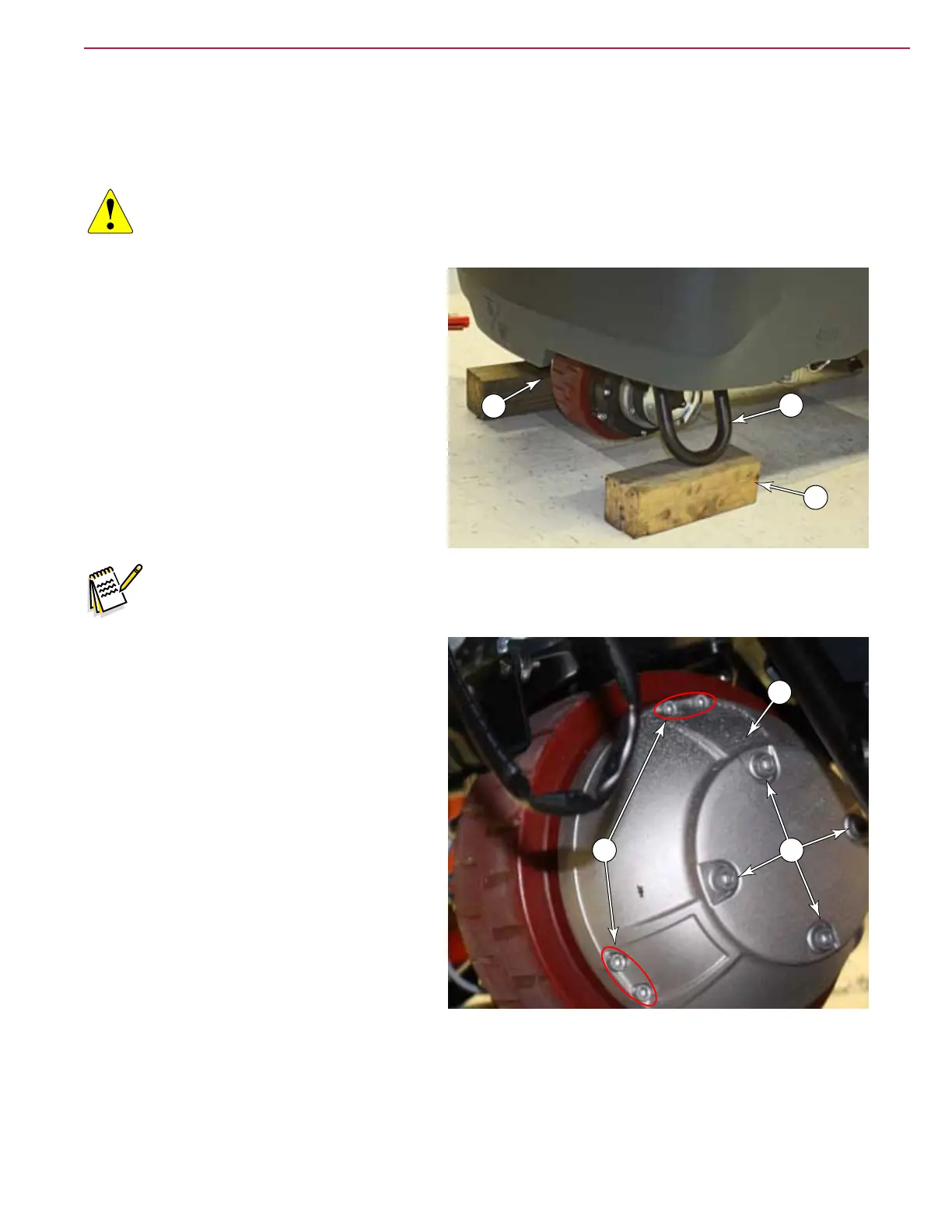

Note: The drive hub screws may contain thread locking compound. The best method for releasing

locking compound is to apply mild heat to the screws. The compound begins to loosen up at

just over 150°F (65°C). If you need to apply heat, make sure to remove the plastic cover.

5. As necessary, apply a mild heat to the 4

screws (E) that secure the hub (D) to the

drive disk (G, shown later). It doesn’t take

a lot of heat nor high temperature. The

goal is just to warm the threads to around

150°F (65°C) to soften the thread locking

compound.

6.

7. While each screw is still warm from heating,

use a 6mm hex key to loosen the 4 screws

(E). A low-power impact driver may be

helpful, but use caution to not sheer the

screws or cam out the heads.

8. Using a 5mm hex key, remove the six screws

(F) that secure the drive hub to the wheel

rim. (The hub is lightly pressed to the drive

disk (G), and will come loose later.)

B

C

A

EF

D

Loading...

Loading...