179Service Manual – SC5000 34 - Scrub System, Disc

Scrub Control

Scrub pressure is controlled by monitoring the motor amperage from both brush motors. If the combined

brush motor current is below its target amperage, the deck is lowered slightly to increase brush pressure. If

the combined amperage is above the target amperage, the deck is raised slightly. Additionally, if either one

of the motors is operating above its maximum allowed amperage, the deck is raised.

The motor amperage is sampled every 250ms, but adjustments are made only at 45 second intervals to lter

out minor variations in the oor. The instantaneous amperage readings are averaged for the 45 second

interval.

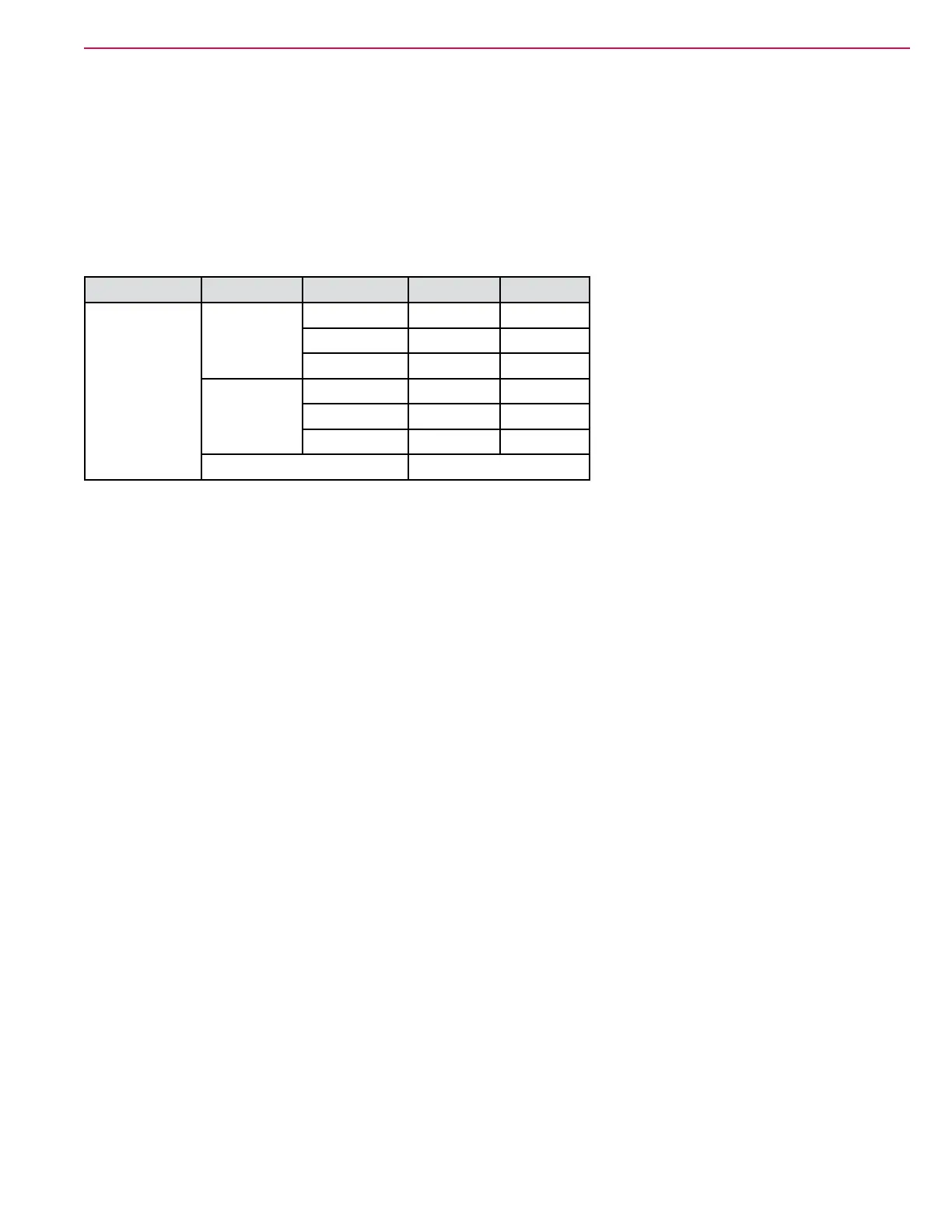

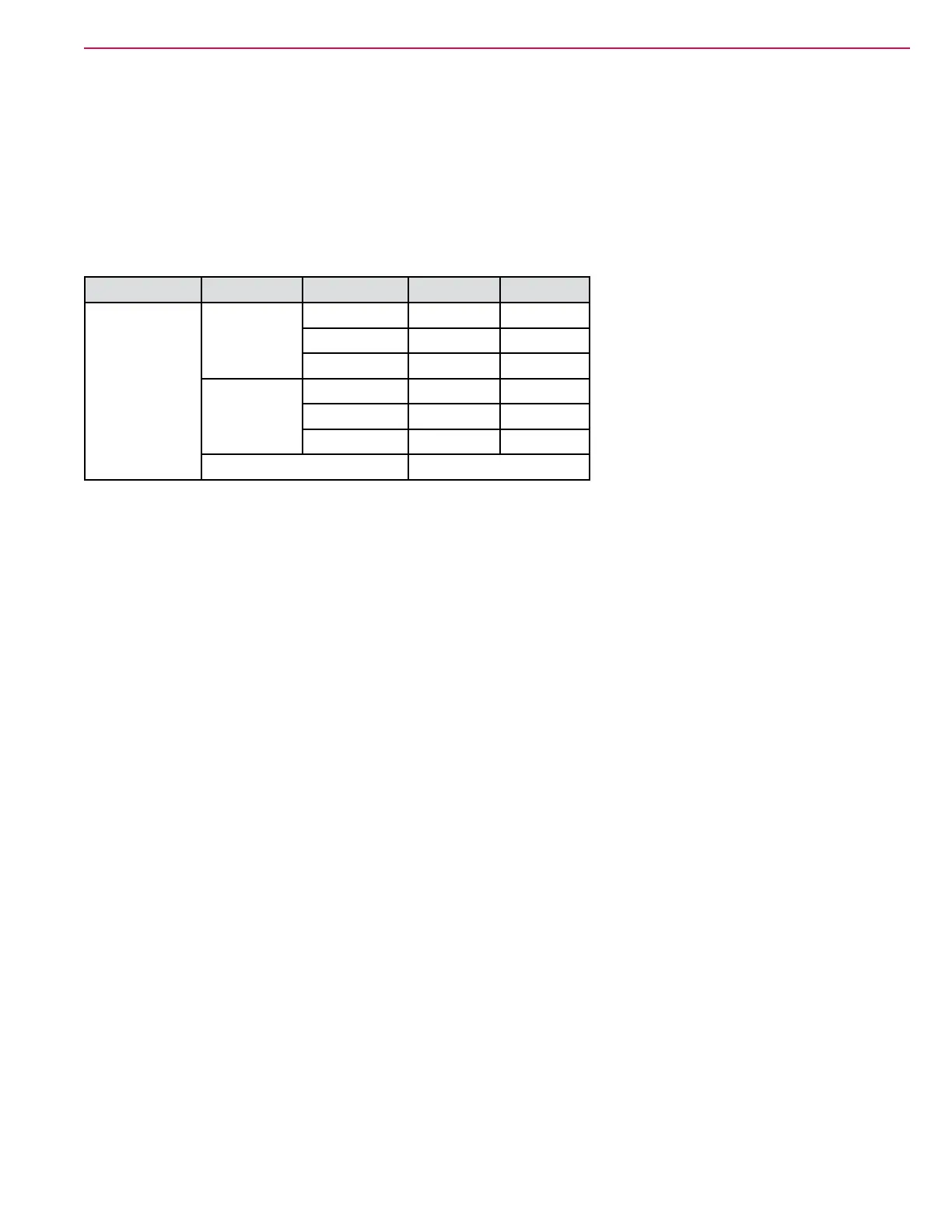

Deck Type Floor Type Scrub Level Min Amps Max Amps

34D

860D

Standard

Low 20 30

High 30 40

Extreme 40 50

Smooth

Low 15 25

High 25 35

Extreme 35 45

Individual Motor Max 25

Operational Mode Prerequisites

Before the main controller can activate any of the operational modes, it must rst check that the appropriate

prerequisites are met.

• Scrub System Outputs

– Brush Motors M1 and M2 or Deck Actuator M7 (seat switch must be closed to enter scrub mode)

◦ No scrub system fault (brush motors and actuator motor)

◦ No recovery system fault (vac motors and squeegee)

◦ Throttle command not equal to zero

◦ No Estop inhibit

◦ No impact lockout inhibit

◦ No low voltage cut out inhibit (rst or second stage)

◦ No RTF inhibit

Loading...

Loading...