21Service Manual – SC5000 04 - Control System

Drive Controller

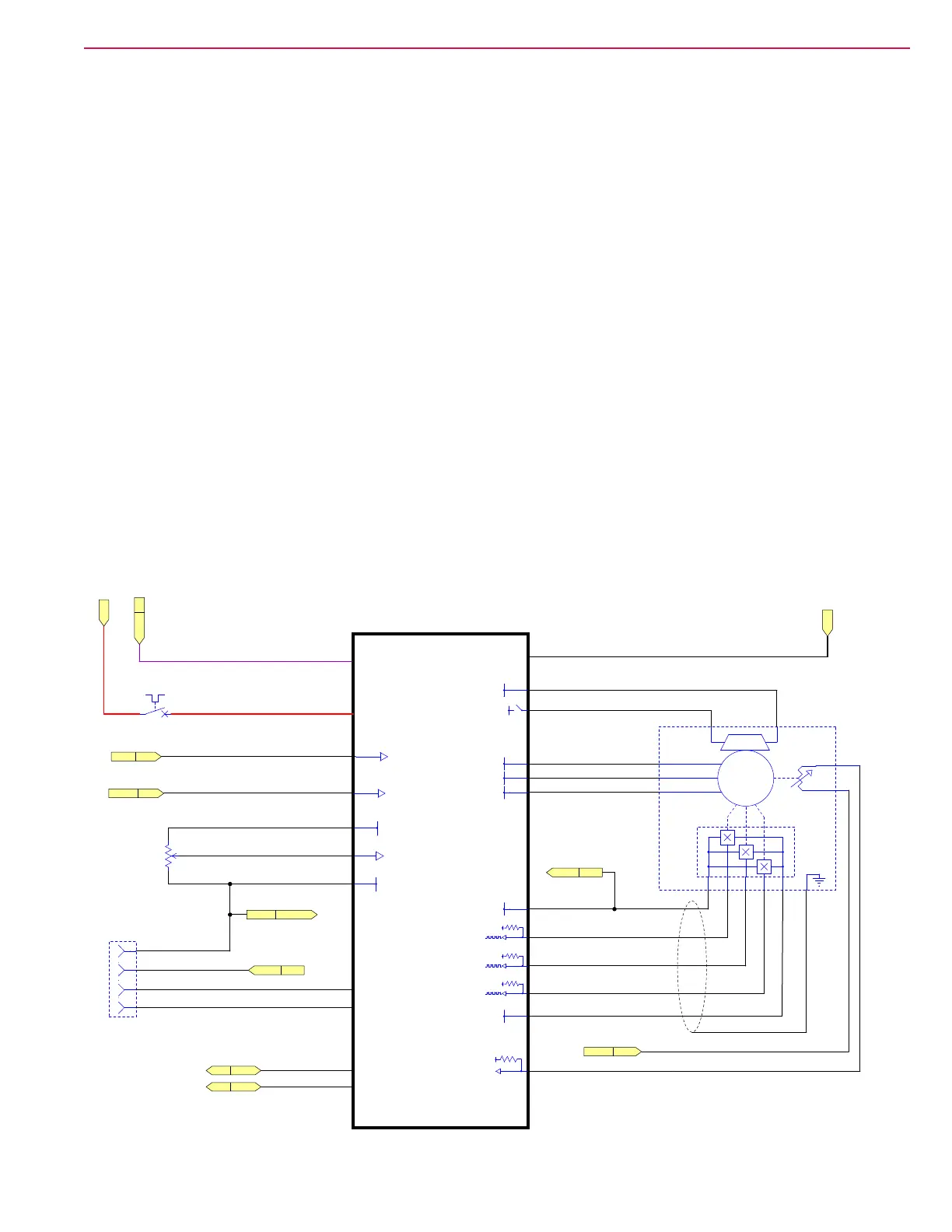

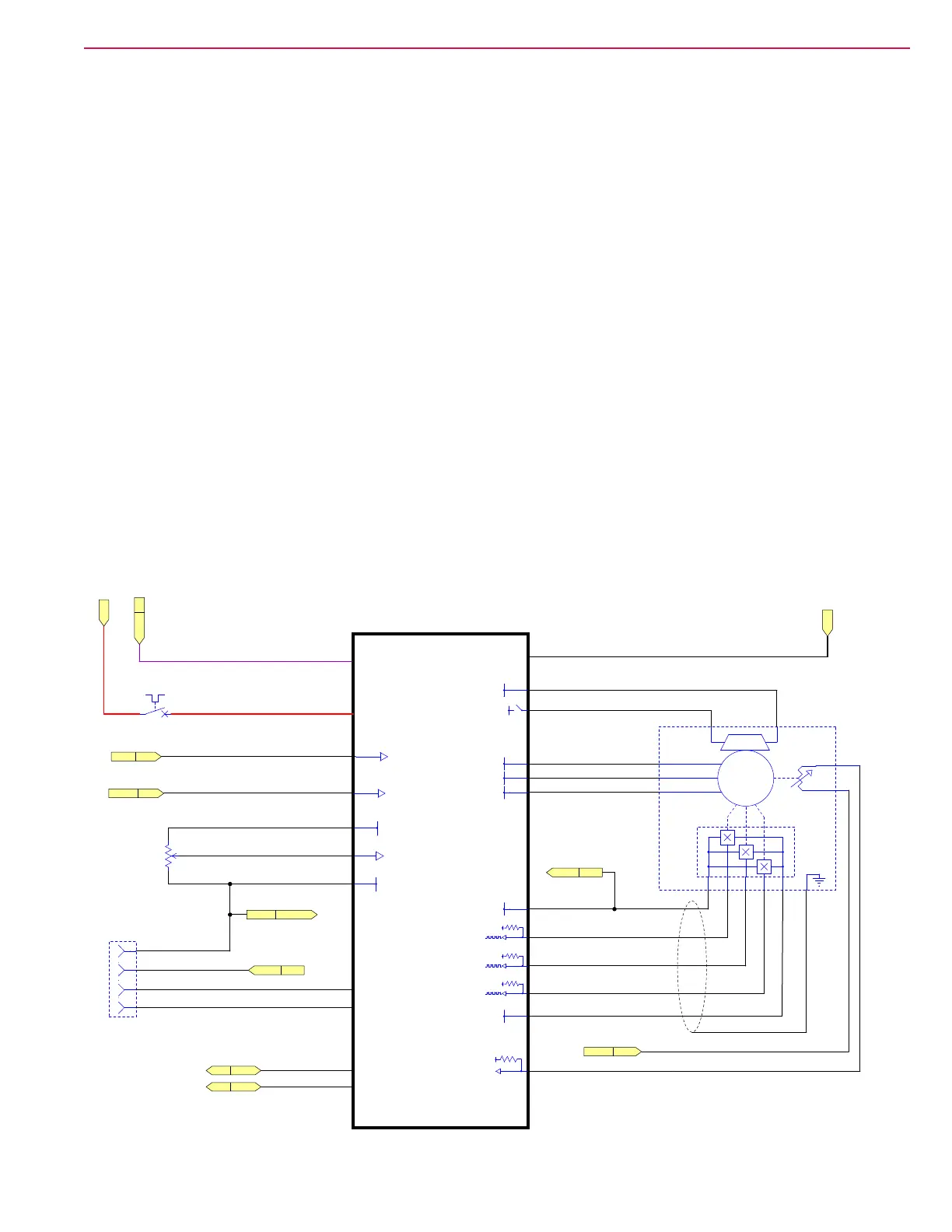

The drive controller operates and monitors the wheel motor. It generates a 3-phase Pulse Width Modulated

(PWM) power control to the wheel motor. Even though it is actually DC power, it resembles a 3-phase

system because the polarity reversals and zero-crossings resemble a 3-phase AC system. This pseudo

3-phase power permits the wheel motor to achieve full torque at near zero rpm, and very precise position

control.

In order to generate this pseudo 3-phase signal, the drive controller needs to know the exact rotational

position of the rotor inside the wheel motor. This is referred to as Remotely Commutated (i.e. brushless

motor). The motor tells the controller what its rotational position is, and which of its 3 primary windings

should be energized in order to rotate in the desired direction. This is accomplished with a set of 3 hall effect

encoders inside the motor that send pulsed timing signals back to the controller to identify its exact position.

The controller also monitors the internal temperature of the motor to protect it from damage due to

overheating.

The drive controller receives its logic power from the KSI relay, but it also has its own high-power input

through the 70 amp circuit breaker, CB2. When the main machine controller has not energized the KSI

relay, the drive controller is off. The drive controller also has 2 enabling inputs directly from the operator’s

seat switch, and the E-stop button. If either one of these switches is open, the drive is disabled, but has

power.

The drive controller receives forward and reverse direction commands from the Main Machine Controller via

the CANBus, and receives its speed control directly from the operator’s foot pedal. The drive pedal sensor

is a hall effect rotary position sensor with a PWM output that simulates the voltage output from a variable

resistor. The drive controller receives the varying voltage input from 1 to 4 volts. The low voltage 1 is

considered neutral, and as the voltage increases, so does the speed commanded by the operator.

CB2

A4

Drive Controller

Pedal

Drive

EM Brake

Motor

Wheel

[BLDC]

Programmer

Connector

X219

RED/VIO

VIO

BLU

GRY

VIO/YEL

GRY

RED/VIO

PNK/BLU

PNK/YEL

YEL

BLU/GRY

BLU/YEL

VIO

RED

RED

RED

RED

RED

VIO/ORN

GRY

VIO/GRN

RED

BLK

J5-15

J5-9

J5-8

J5-12

J5-21

J5-20

J5-19

J5-18

J5-3

J5-2

J5-22

J5-4

J5-6

J5-13

J5-10

J5-1

B+ Lug

J4-1

J4-2

B- Lug

+5V

B-

15V

15V

15V

M

3Ø

U

Vcc Gnd

H

U

H

V

H

W

V

W

1 2 3 6

3

4

Encoder

4 5

Thermistor

M10

Y1

12

1 2

C

B

A

1

2

3

4

70 AMP

KSI

DATA

CL

EM BRAKE

U1

B-

E-Stop

TEMP SENSOR1

W

I/O GND

V1

WIPER

R4

W1

15V

5V

U

36V

Seat SW

V

CAN(1) L

CAN(1) H

B-

B+

KSI MMC

CAN1HMMC

CAN1LMMC

Batt+

E-Stop MMC

Seat SW MMC

Sig Gnd Thermistor

Sig Gnd DRIVE

15V Out DRIVE

15V Out PROG

Batt-

Loading...

Loading...