78Service Manual – SC5000 14 - Wheel System, Non-Traction

Removal and Installation

Rear Wheel Bearings and Seal

The rear wheel bearings are sealed and do not require

lubrication. Severely worn bearings may be detected

by wheel wobble or grinding sounds. A less obvious

symptom of bearing failure is when the wheel easily

freewheels when spun by hand with the machine

elevated off the ground. A good sealed bearing should

have a slight but smooth resistance to freewheel.

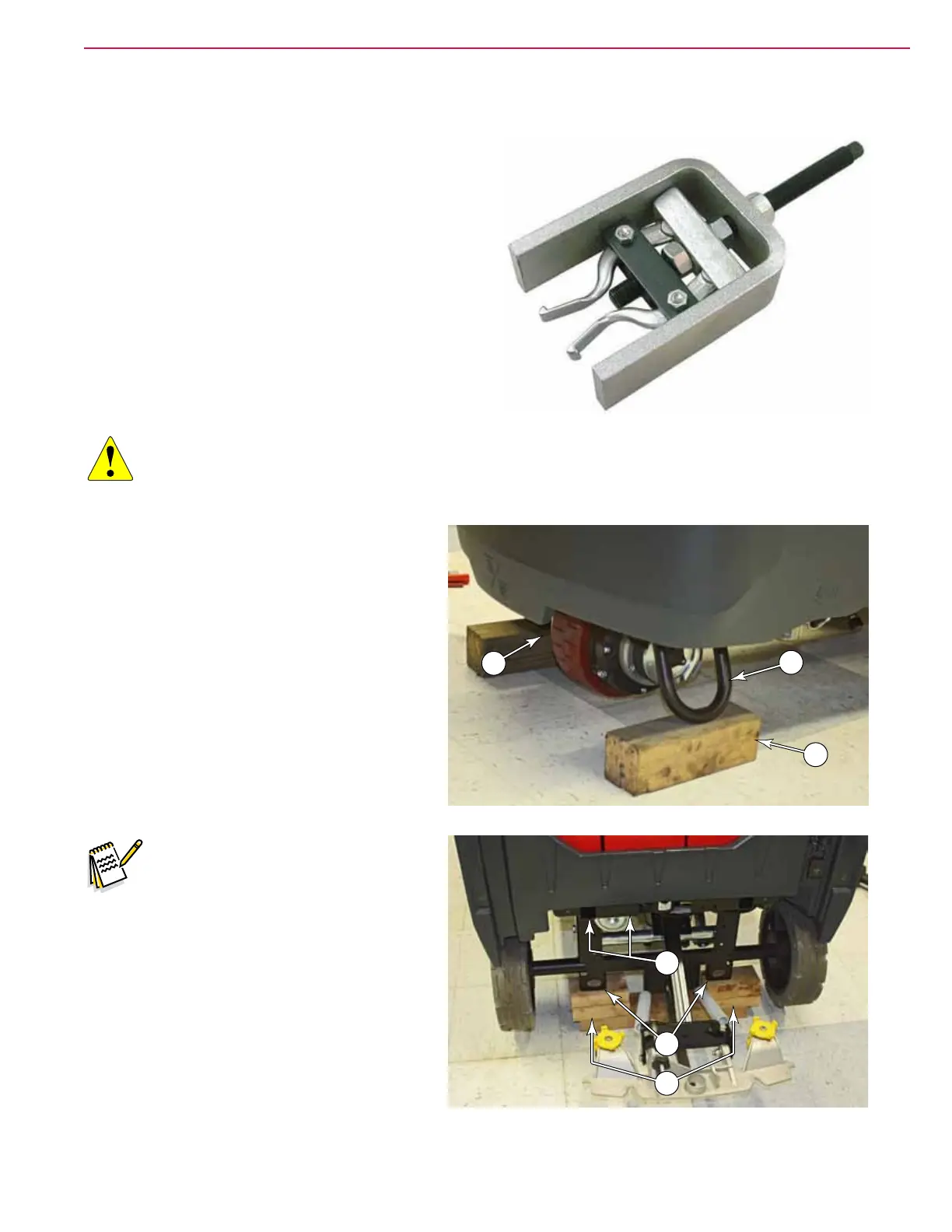

The wheel bearings are pressed into the wheel hub. To

complete this procedure, you will need a bearing puller

and a press. There are many different types of bearing

pullers that will operate on the internal bore of a bearing

(35mm in this case). As one example, a pilot bearing

puller is shown to the right.

WARNING: Never work under a machine without safety

stands or blocking to support the machine.

− Never jack the rear of the machine without

rst stabilizing the front of the machine.

1. To reduce the weight of the machine, drain

both the recovery and solution tanks.

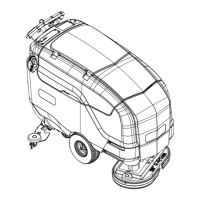

2. Using the lifting point (A) located on the

right anti-tip hoop, raise the front of the

machine, and place support blocks (C) under

both anti-tip hoops (B).

• Failure to stabilize the front of the

machine can result in the machine being

unstable when the rear end is lifted.

Note: The machine is shown with

the recovery tank and squeegee

removed for clarity. It is not

necessary to remove them for this

procedure.

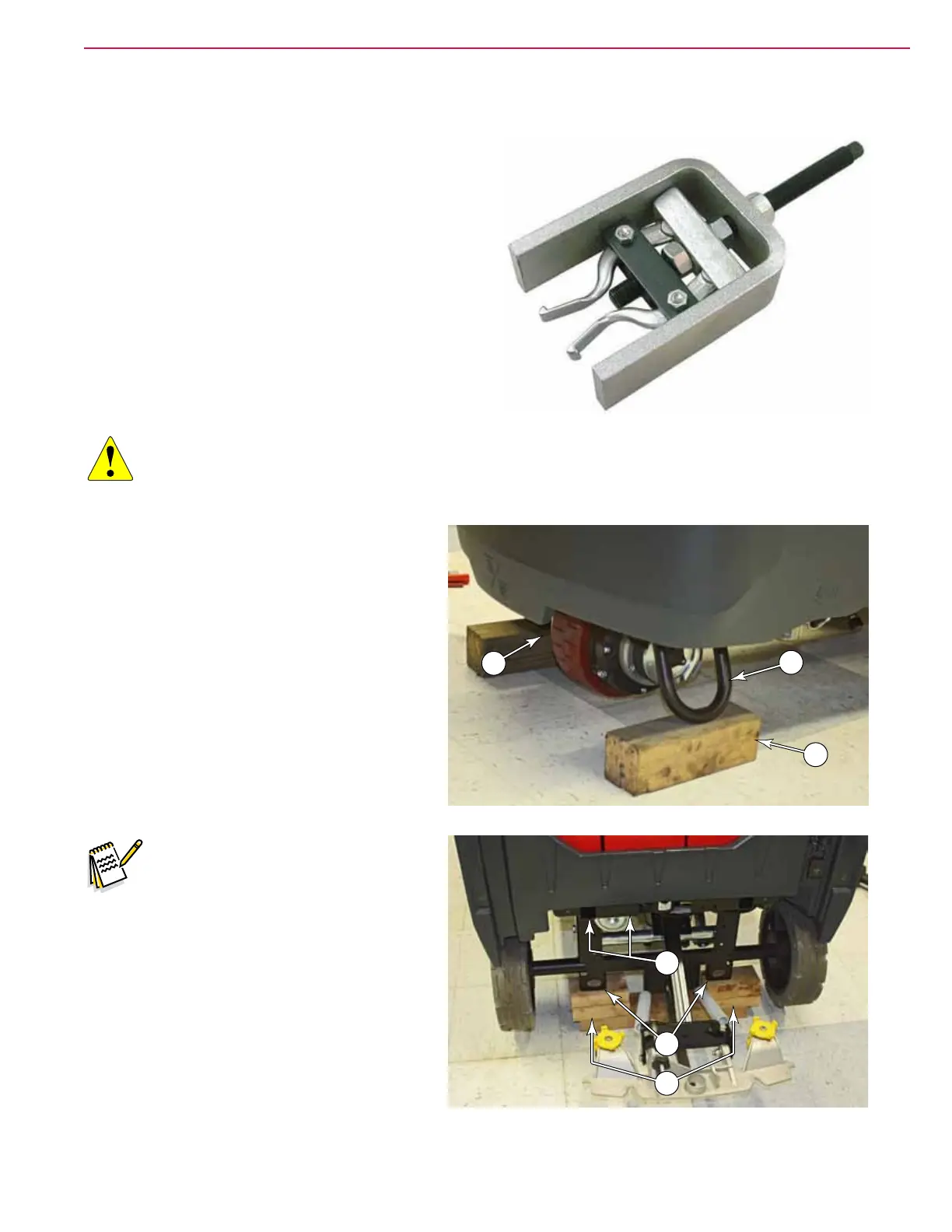

3. Using the left side of the chassis, as close to

the center as possible (D), raise the rear of

the machine, and place blocks (F) under the

tie-down eyelets (E).

B

C

A

E

F

D

Loading...

Loading...