2 Instruction Descriptions

2-62

NJ-series Instructions Reference Manual (W502)

MC and MCR

* The number is automatically registered by the Sysmac Studio. You do not need to set it.

Master control is used to stop processing or place in an equivalent status all POUs in a specified region

of a program. You can use master control to easily control the execution conditions for a relatively long

segment of processing.

The region in the program for which master control is applied is called the master control region. You

place the MC instruction at the start of the master control region and the MCR instruction at the end.

When the value of the master control input In changes to FALSE, the outputs for all LD instructions that

are connected to the left bus bar in the master control region are forced to change to FALSE. This is

called a master control reset.

When master control is reset, the POUs that follow the LD instructions, as a rule, operate as if the exe-

cution condition is FALSE. There are, however, some POUs that operate differently. This is explained

later.

MC: Marks the starting point of a master control region and resets the master control region.

MCR: Marks the end point of a master control region.

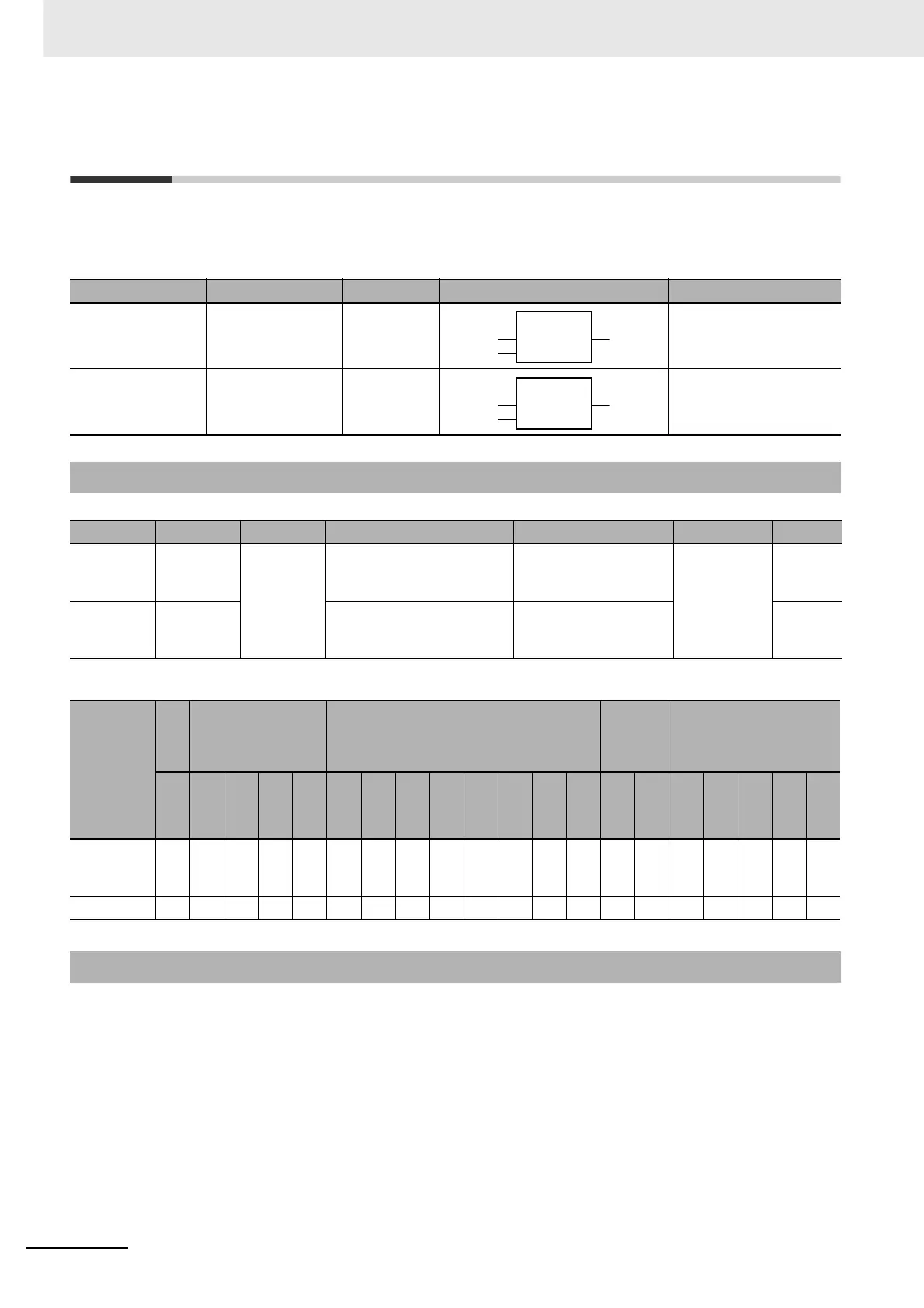

Instruction Name FB/FUN Graphic expression ST expression

MC Master Control

Start

--- None

MCR Master Control End --- None

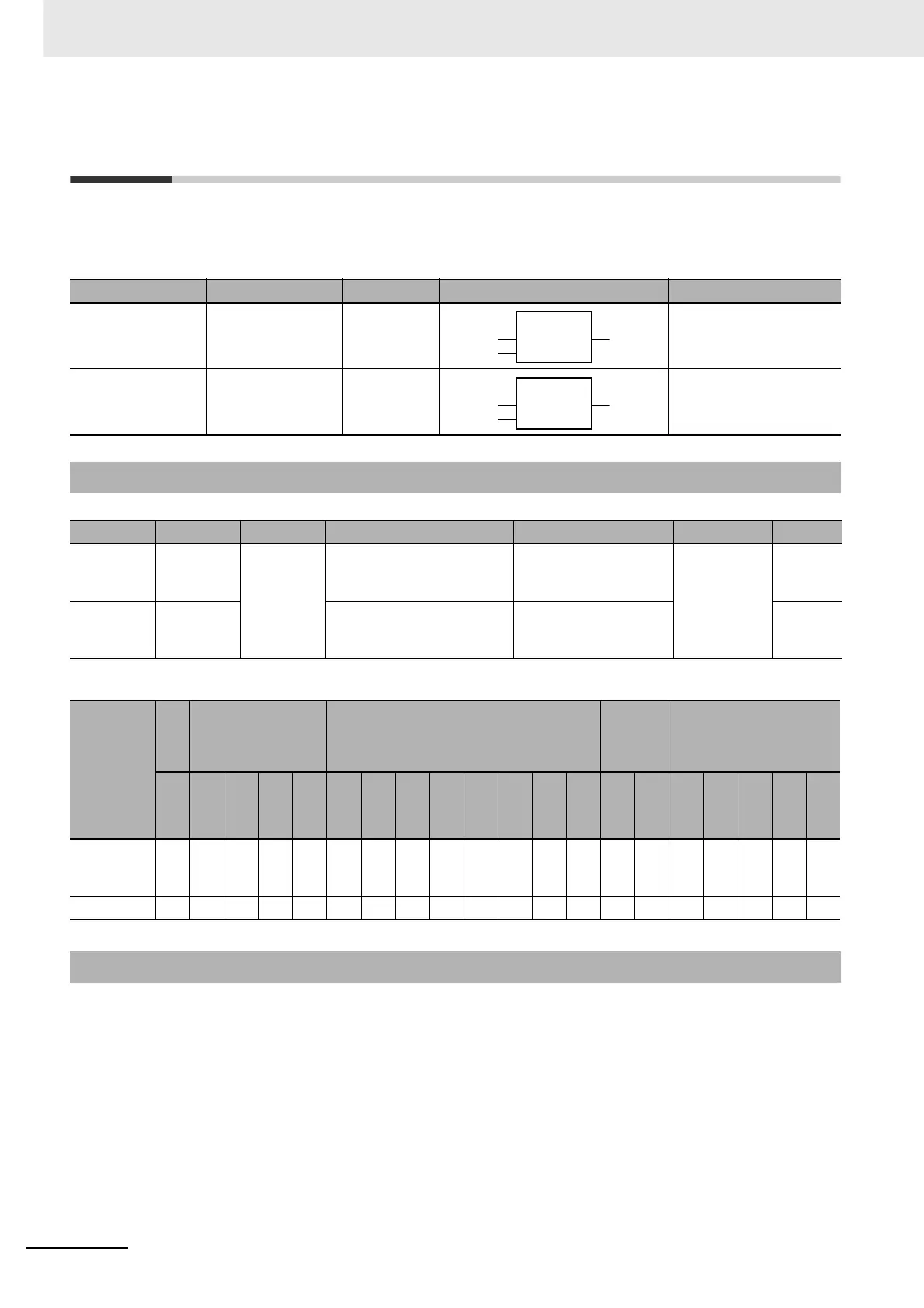

Variables

Name Meaning I/O Description Valid range Unit Default

In (MC

instruction

only)

Master

control

input

Input

FALSE: Resets the master

control region.

Depends on data type.

---

TRUE

MCNo Master

control

number

Master control number 0 to 14* 1

Boolean

Bit strings Integers

Real

numbers

Times, durations,

dates, and text strings

BOOL

BYTE

WORD

DWORD

LWORD

USINT

UINT

UDINT

ULINT

SINT

INT

DINT

LINT

REAL

LREAL

TIME

DATE

TOD

DT

STRING

In (MC

instruction

only)

OK

MCNo OK

Function

MC

In ENO

MCNo

MCR

EN ENO

MCNo

Loading...

Loading...