Startup Procedure and

Test Run

4

4.8 Fine Tuning during Test Runs (Adjust the Control Function)

SIEPYEUOQ2A01A AC Drive Q2A Technical Manual 159

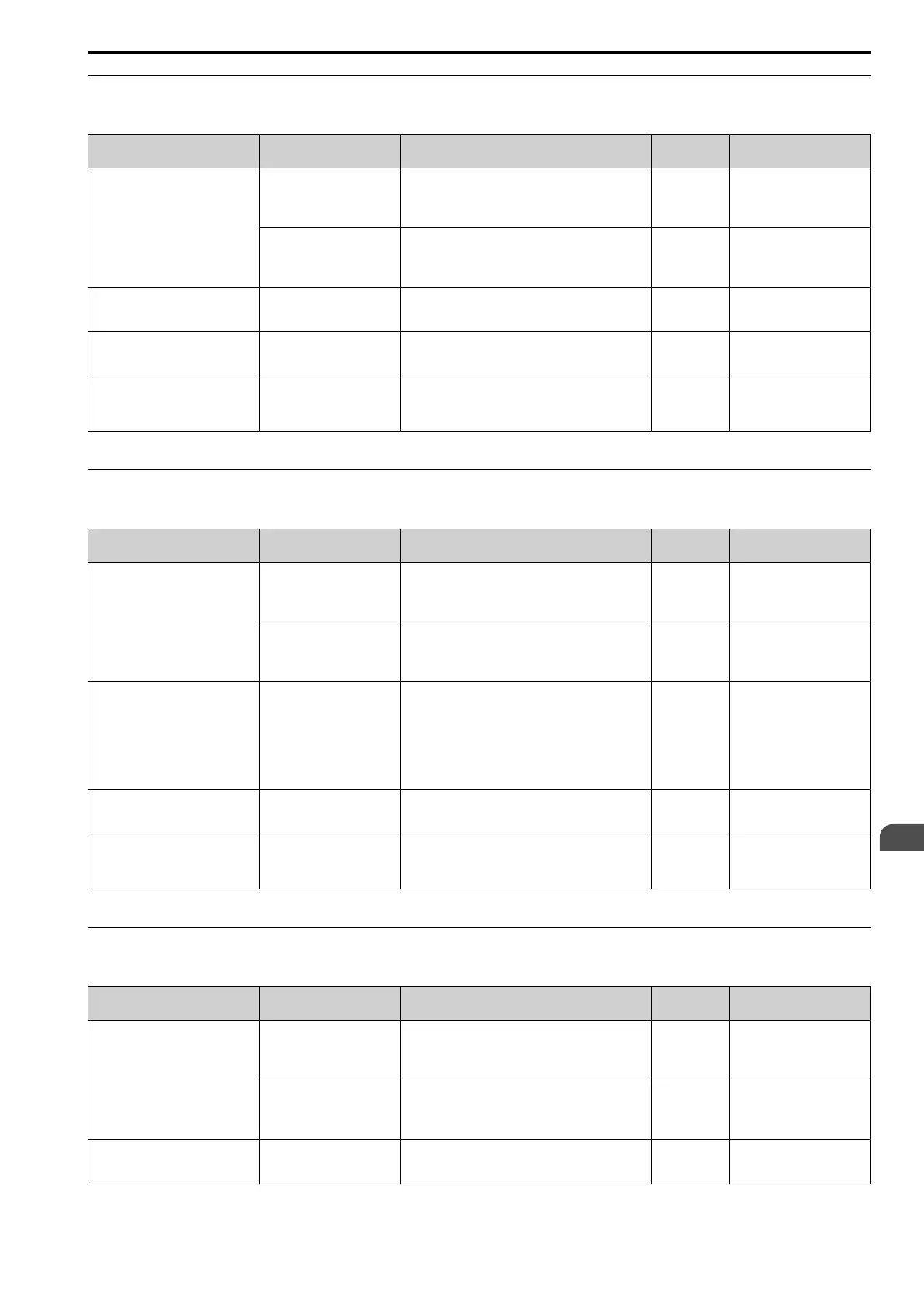

◆ Advanced Open Loop Vector Control Method for PM

Table 4.22 Parameters for Fine Tuning the Drive (Advanced Open Loop Vector Control Method for PM)

Issue Parameter Number Solution Default

Setting

Recommended Setting

• Torque or speed response are

slow.

• Hunting or oscillation

• High speed

C5-01 [ASR PGain 1]

• Low speed

C5-03 [ASR PGain 2]

• If torque or speed response are slow, increase the

setting value in increments of 5.00.

• If hunting or oscillation occur, decrease the setting

value.

10.00 5.00 - 30.00

*1

• High speed

C5-02 [ASR ITime 1]

• Low speed

C5-04 [ASR ITime 2]

• If torque or speed response are slow, decrease the

setting value.

• If hunting or oscillation occur, increase the setting

value.

0.500 s 0.300 to 1.000 s

*1

The drive cannot find ASR

proportional gain or integral time for

low speed or high speed.

C5-07 [ASR Gain Switch

Frequency]

Change the ASR proportional gain and ASR integral

time to conform to the output frequency.

0.0 %

0.0% to maximum rotation

speed

Hunting or oscillation C5-06 [ASR Delay Time]

If the rigidity of the machine is unsatisfactory and

vibration is possible, increase the setting value in

increments of 10 ms.

16 ms 16 to 35 ms

*1

Step-out

E1: V/F PARAMETER

MOTOR 1parameters, E5: PM

MOTOR SETTINGS

parameters

Refer to the motor nameplate or test report and set E1:

V/F PARAMETER MOTOR 1 or E5: PM MOTOR

SETTINGS parameters correctly.

- -

*1 The best values for a no-load operation are different than the best values for actual loading operation.

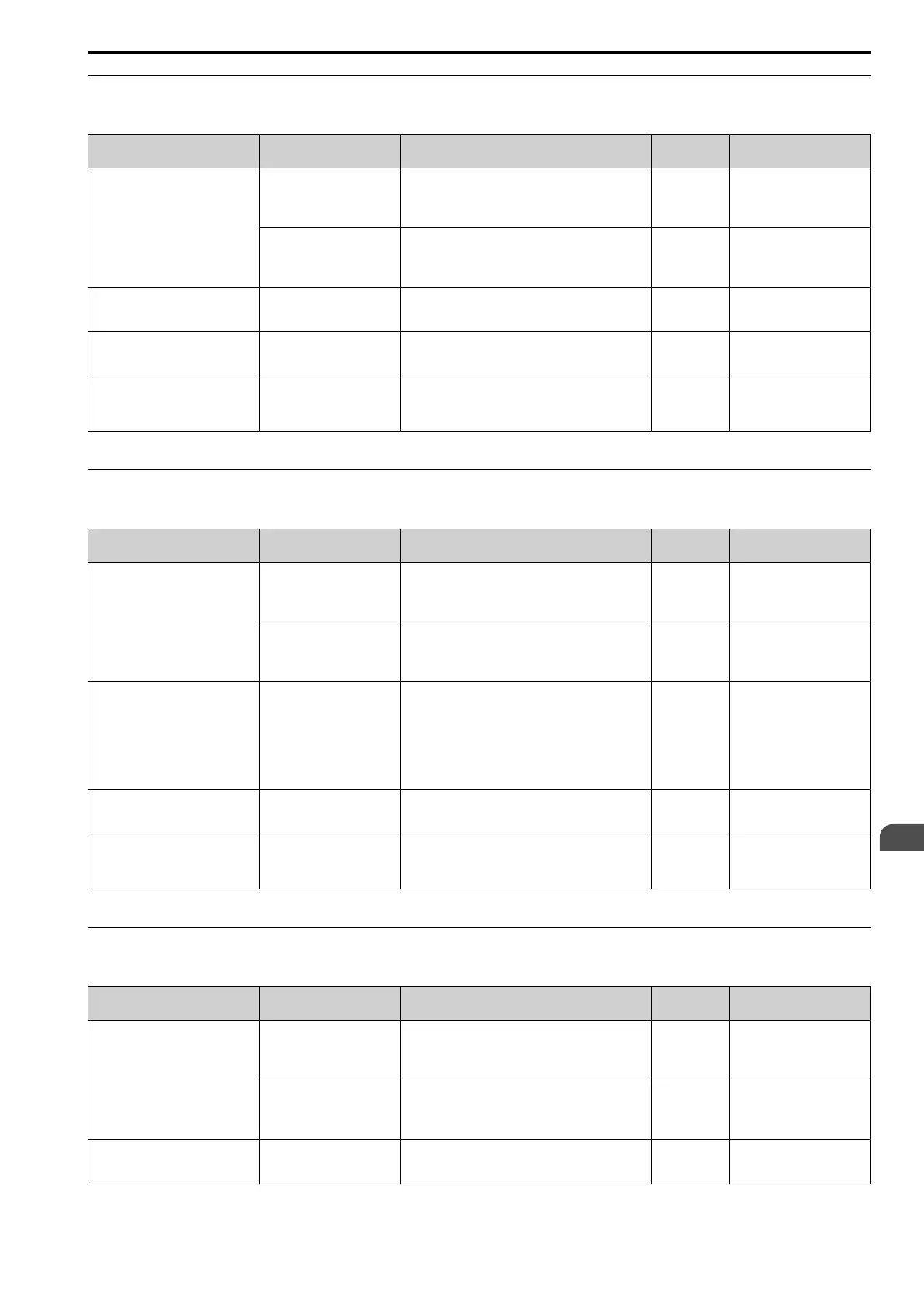

◆ Closed Loop Vector Control Method for PM

Table 4.23 Parameters for Fine Tuning the Drive (Closed Loop Vector Control Method for PM)

Issue Parameter Number Solution Default

Setting

Recommended Setting

• Torque or speed response are

slow.

• Hunting or oscillation

• High speed

C5-01 [ASR PGain 1]

• Low speed

C5-03 [ASR PGain 2]

• If torque or speed response are slow, increase the

setting value in increments of 5.00.

• If hunting or oscillation occur, decrease the setting

value.

20.00 10.00 - 50.00

*1

• High speed

C5-02 [ASR ITime 1]

• Low speed

C5-04 [ASR ITime 2]

• If torque or speed response are slow, decrease the

setting value.

• If hunting or oscillation occur, increase the setting

value.

0.500 s 0.300 to 1.000 s

*1

The drive cannot find speed response

for low speed or high speed.

• C5-07 [ASR Gain Switch

Frequency]

• High speed

C5-01 [ASR PGain 1]

C5-02 [ASR ITime 1]

• Low speed

C5-03 [ASR PGain 2]

C5-04 [ASR ITime 2]

Change the ASR proportional gain and ASR integral

time to conform to the output frequency.

0.0 %

0.0% to maximum rotation

speed

Hunting or oscillation C5-06 [ASR Delay Time]

If the rigidity of the machine is unsatisfactory and

vibration is possible, increase the setting value in

increments of 10 ms.

4 ms 4 to 20 ms

*1

Step-out

E1: V/F PARAMETER

MOTOR 1parameters,

E5: PM MOTOR SETTINGS

parameters

Refer to the motor nameplate or test report and set E1:

V/F PARAMETER MOTOR 1 or E5: PM MOTOR

SETTINGS parameters correctly.

- -

*1 The best values for a no-load operation are different than the best values for actual loading operation.

◆ EZ Open Loop Vector Control Method

Table 4.24 Parameters for Fine Tuning the Drive (EZ Open Loop Vector Control Method)

Issue Parameter Number Solution Default

Setting

Recommended Setting

• Torque or speed response are

slow.

• Hunting or oscillation

• High speed

C5-01 [ASR PGain 1]

• Low speed

C5-03 [ASR PGain 2]

• If torque or speed response are slow, increase the

setting value in increments of 5.00.

• If hunting or oscillation occur, decrease the setting

value.

10.00 10.00 - 50.00

*1

• High speed

C5-02 [ASR ITime 1]

• Low speed

C5-04 [ASR ITime 2]

• If torque or speed response are slow, decrease the

setting value.

• If hunting or oscillation occur, increase the setting

value.

0.500 s 0.300 to 1.000 s

*1

The drive cannot find ASR

proportional gain or integral time for

low speed or high speed.

C5-07 [ASR Gain Switch

Frequency]

Change the ASR proportional gain and ASR integral

time to conform to the output frequency.

0.0%

0.0% to maximum rotation

speed

Loading...

Loading...