8.2 Inspection

306 SIEPYEUOQ2A01A AC Drive Q2A Technical Manual

8.2 Inspection

Power electronics have limited life and can show changes in performance and deterioration of performance after

years of use in usual conditions. To help prevent these problems, it is important to do preventive maintenance and

regular inspection, and replace parts on the drive.

Drives contain different types of power electronics, for example power transistors, semiconductors, capacitors,

resistors, fans, and relays. The electronics in the drive are necessary for correct motor control.

Follow the inspection lists in this chapter as a part of a regular maintenance program.

• Examine the drive one time each year at a minimum.

• The operating conditions, environmental conditions, and use conditions will have an effect on the examination

frequency for connected equipment.

• Examine the drive more frequently if you use the drive in bad conditions or in these conditions:

– High ambient temperatures

– Frequent starting and stopping

– Changes in the AC power supply or load

– Too much vibration or shock loading

– Dust, metal dust, salt, sulfuric acid, or chlorine atmospheres

– Unsatisfactory storage conditions.

DANGER! Electrical Shock Hazard. Do not examine, connect, or disconnect wiring on an energized drive. Before servicing,

disconnect all power to the equipment and wait for the time specified on the warning label at a minimum. The internal capacitor

stays charged after the drive is de-energized. The charge indicator LED extinguishes when the DC bus voltage decreases

below 50 Vdc. When all indicators are OFF, remove the covers before measuring for dangerous voltages to make sure that the

drive is safe. Failure to obey will cause death or serious injury.

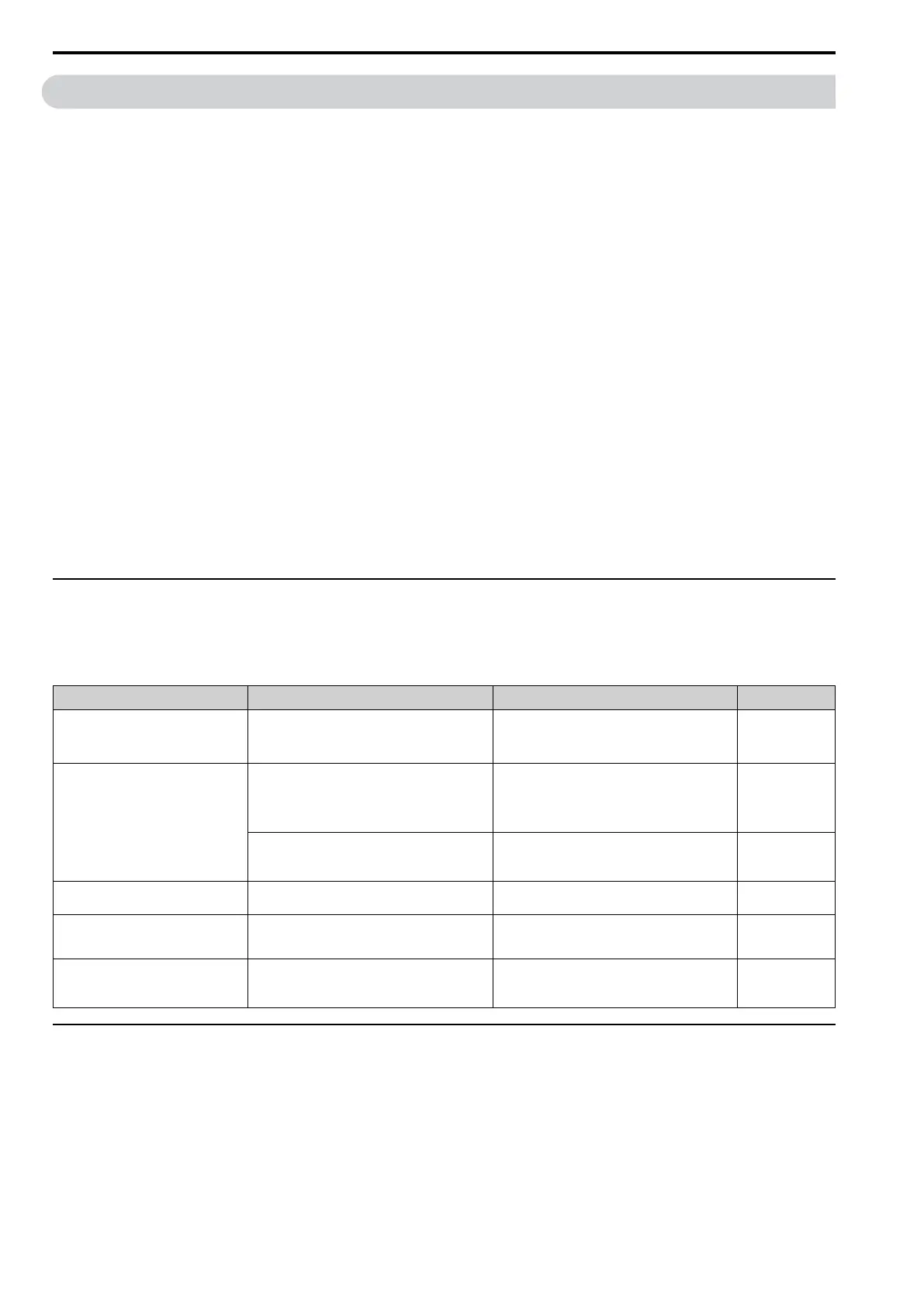

◆ Recommended Daily Inspection

Examine the items in the following table each day to make sure that the components do not wear out or fail. Make

a copy of this checklist and put a check mark in the “Checked” column after each inspection.

Table 8.1 Daily Inspection Checklist

Inspection Area Inspection Points Corrective Action Checked

Motor

Examine for unusual oscillation or noise coming from

the motor.

• Check the load coupling.

• Measure motor vibration.

• Tighten all loose components.

Cooling System

Examine for unusual heat from the drive or motor and

visible discoloration.

• Check for a load that is too heavy.

• Tighten loose screws.

• Check for a dirty heatsink or motor.

• Check the ambient temperature.

Examine the cooling fans, circulation fans, and circuit

board cooling fans.

• Check for a clogged or dirty fan.

• Use the performance life monitor to check for

correct fan operation.

Surrounding Environment

Make sure that the installation environment is

applicable.

Remove the source of contamination or correct

unsatisfactory environment.

Load

Make sure that the drive output current is not more

than the motor or drive rating for an extended period

of time.

• Check for a load that is too heavy.

• Check the correct motor parameter settings.

Power Supply Voltage Examine main power supply and control voltages.

• Correct the voltage or power supply to agree with

nameplate specifications.

• Verify all main circuit phases.

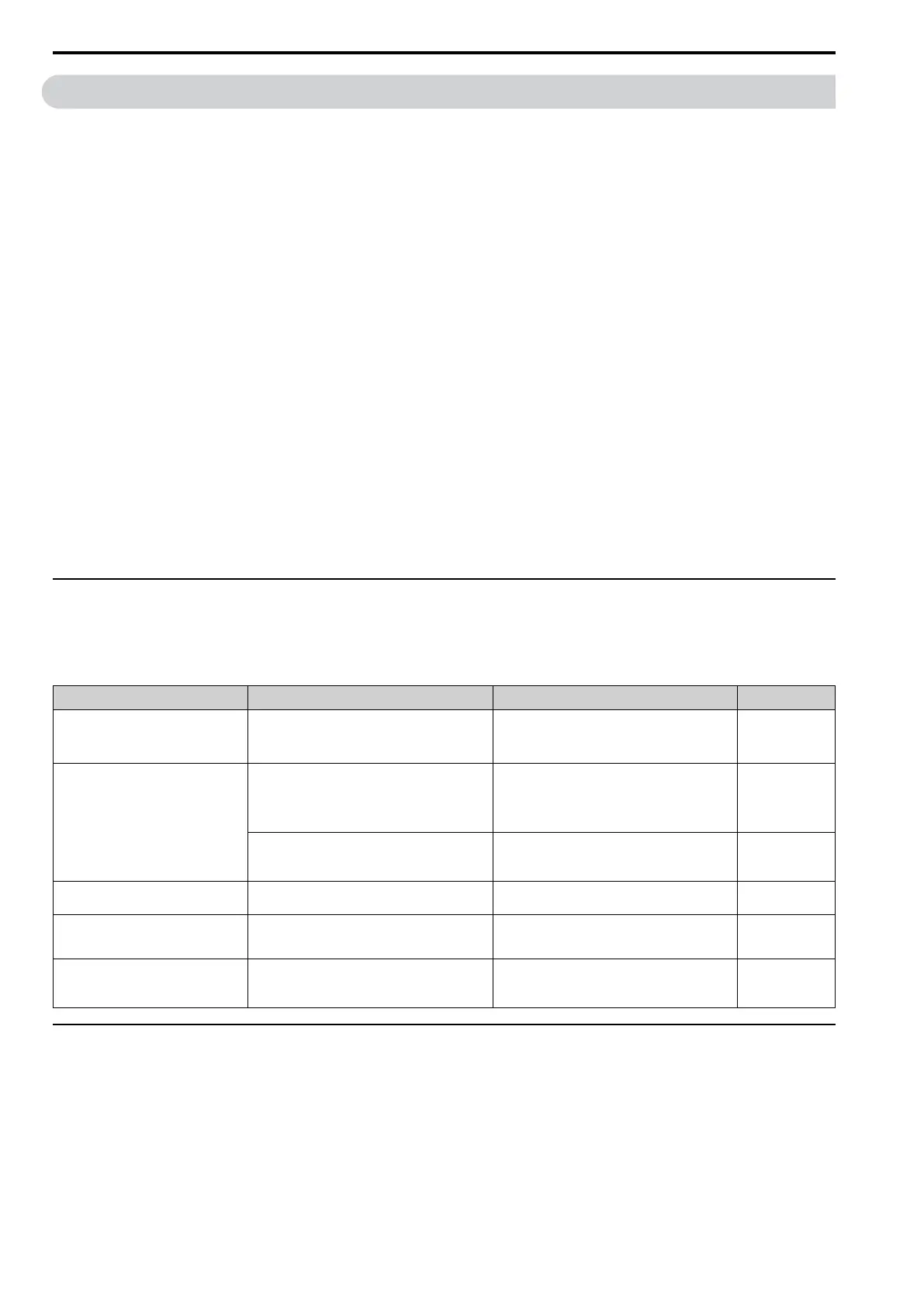

◆ Recommended Periodic Inspection

Examine the items in the following tables one time each year at a minimum. The operating conditions,

environmental conditions, and use conditions will have an effect on the examination frequency for connected

equipment. You must use your experience with the application to select the correct inspection frequency for each

drive installation. Periodic inspections will help to prevent performance deterioration and product failure. Make a

copy of this checklist and put a check mark in the “Checked” column after each inspection.

Loading...

Loading...