Troubleshooting

7

7.4 Faults

SIEPYEUOQ2A01A AC Drive Q2A Technical Manual 257

Code Name Causes Possible Solutions

The PG option card or the encoder on the motor

side is damaged.

Repair the wiring and re-energize the drive, then replace the PG

option card or the encoder if the problem continues.

Note:

• The drive detects this error if it does not detect a Z pulse during one motor rotation.

• Do a Fault Reset to clear the fault.

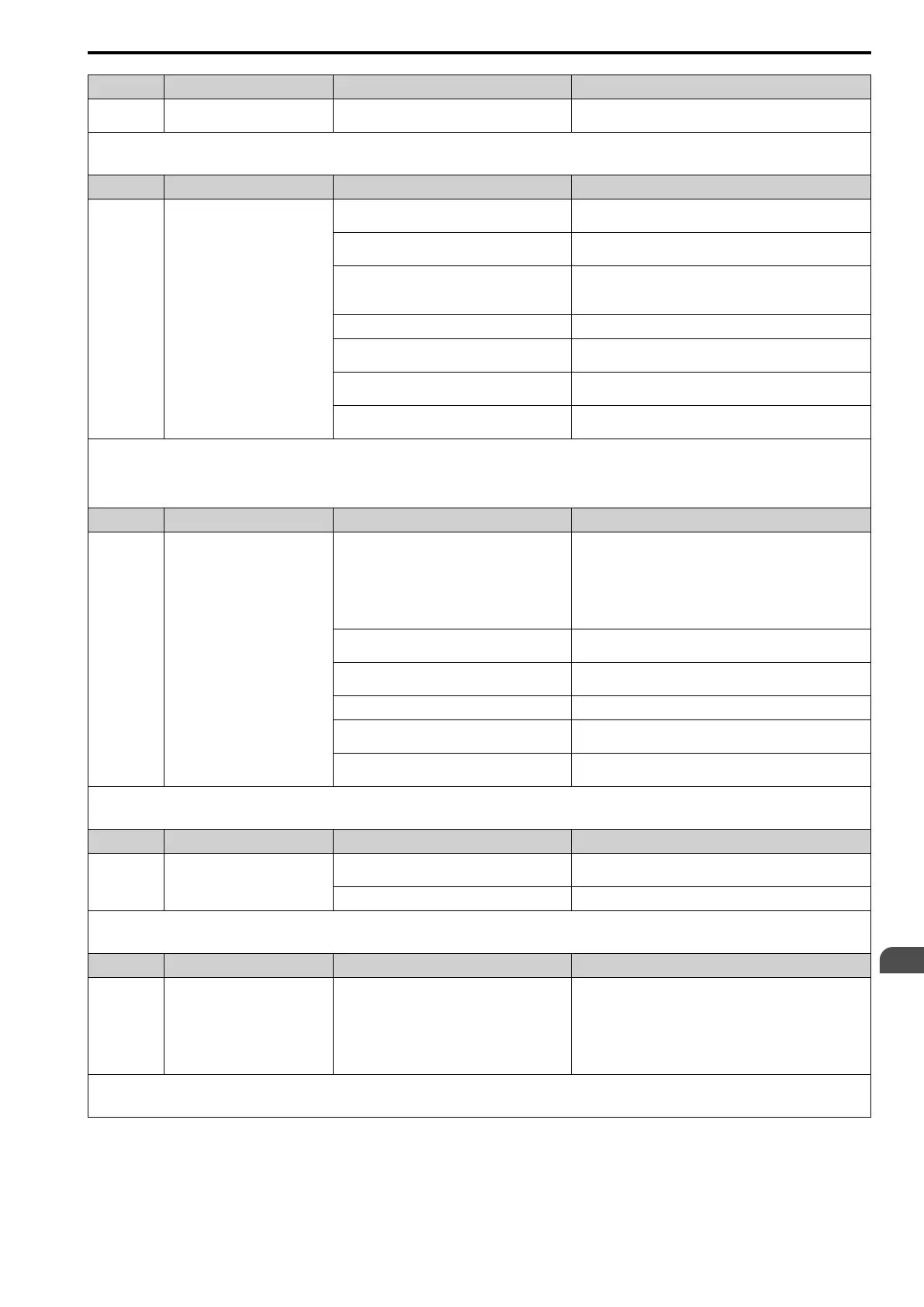

Code Name Causes Possible Solutions

dv3 Inversion Detection

E5-11 [Enc ZPulse Offset] is set incorrectly. Correctly set the value for Δθ to E5-11 as specified by the values

on the motor nameplate.

There is a new encoder or the motor rotation

direction changed.

Do Z Pulse Offset Tuning.

An external force on the load side rotated the motor. • Make sure that the motor is rotating in the correct direction.

• Find and repair problems on the load side that cause the motor

to rotate from the load side.

Noise interference along the encoder cable. Correctly ground the shielded wire of the encoder cable.

The encoder cable is disconnected or incorrectly

wired.

Examine for wiring errors or disconnected wires in the encoder

cable, and repair problems.

The setting for F1-05 [Enc1 Rotat Selection] is the

opposite of the direction of motor rotation.

Correctly connect the motor wiring for each phase (U, V, W).

The PG option card or the encoder on the motor

side is damaged.

Repair the wiring and re-energize the drive, then replace the PG

option card or the encoder if the problem continues.

Note:

• The drive detects this error if:

–the torque reference and acceleration are in opposite directions.

–the speed reference and actual motor speed are more than 30% different for the number of times set to F1-18 [Dev3 Mode Selection].

• Do a Fault Reset to clear the fault.

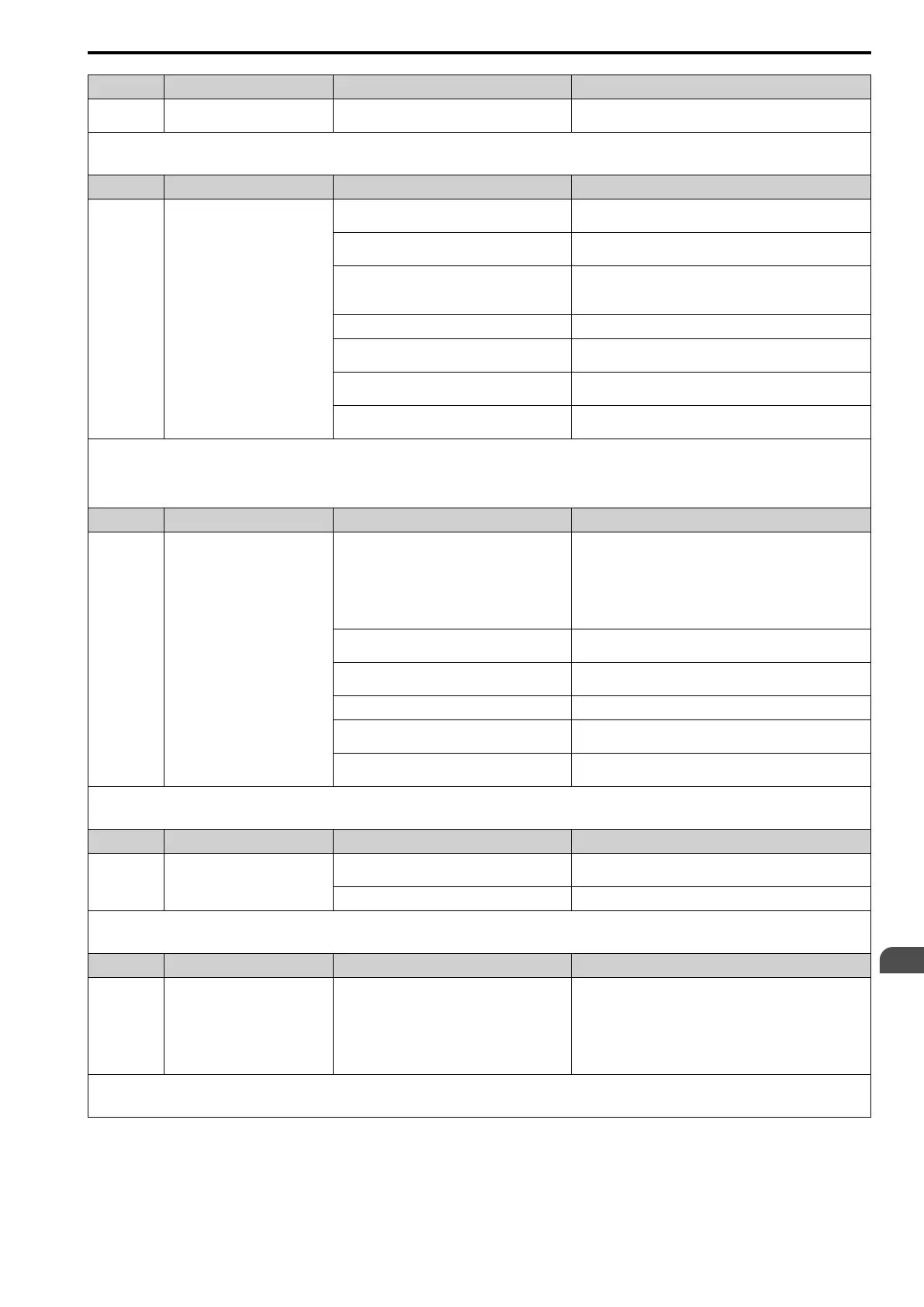

Code Name Causes Possible Solutions

dv4 Inversion Prevention Detection

An external force on the load side moved the motor. • Make sure that the motor is rotating in the correct direction.

• Find and repair problems on the load side that cause the motor

to rotate from the load side.

• Disable detection of this fault for applications that rotate the

motor from the load side in the opposite direction of the speed

reference. The drive will not detect this fault if F1-19 = 0

[Dev4 Mode Selection = Disabled].

E5-11 [Enc ZPulse Offset] is set incorrectly. Correctly set the value for Δθ to E5-11 as specified by the values

on the motor nameplate.

There is a new encoder or the motor rotation

direction changed.

Do Z Pulse Offset Tuning.

Noise interference along the encoder cable Correctly ground the shielded wire of the encoder cable.

The encoder cable is disconnected or incorrectly

wired.

Examine for wiring errors or disconnected wires in the encoder

cable, and repair problems.

The PG option card or the encoder on the motor

side is damaged.

Repair the wiring and re-energize the drive, then replace the PG

option card or the encoder if the problem continues.

Note:

• The drive detects this error if the pulses in the opposite direction of the speed reference are more than the value set in F1-19.

• Do a Fault Reset to clear the fault.

Code Name Causes Possible Solutions

dv7 Polarity Judge Timeout

There is a disconnection in the motor coil winding. Measure the motor line-to-line resistance and replace the motor if

a coil is disconnected.

The screws on the drive output terminals are loose. Tighten the terminal screws to the correct tightening torque.

Note:

• The drive detects this error if it cannot detect polarity in a pre-set length of time.

• Do a Fault Reset to clear the fault.

Code Name Causes Possible Solutions

E5

MECHATROLINK Watchdog

Timer Err

The drive detected a watchdog circuit exception

while it received data from the controller.

Examine the MECHATROLINK cable connection. If this error

occurs frequently, examine the wiring and decrease the effects of

electrical interference as specified by these manuals:

• MECHATROLINK-II Installation Guide (MECHATROLINK

Members Association, manual number MMATDEP011)

• MECHATROLINK-III Installation Guide (MECHATROLINK

Members Association, manual number MMATDEP018)

Note:

• Do a Fault Reset to clear the fault.

• If the drive detects this fault, it will operate the motor as specified by the stop method set in F6-25 [MLII Watchdog Error Sel].

Loading...

Loading...