2000-OSM, F1 2-9

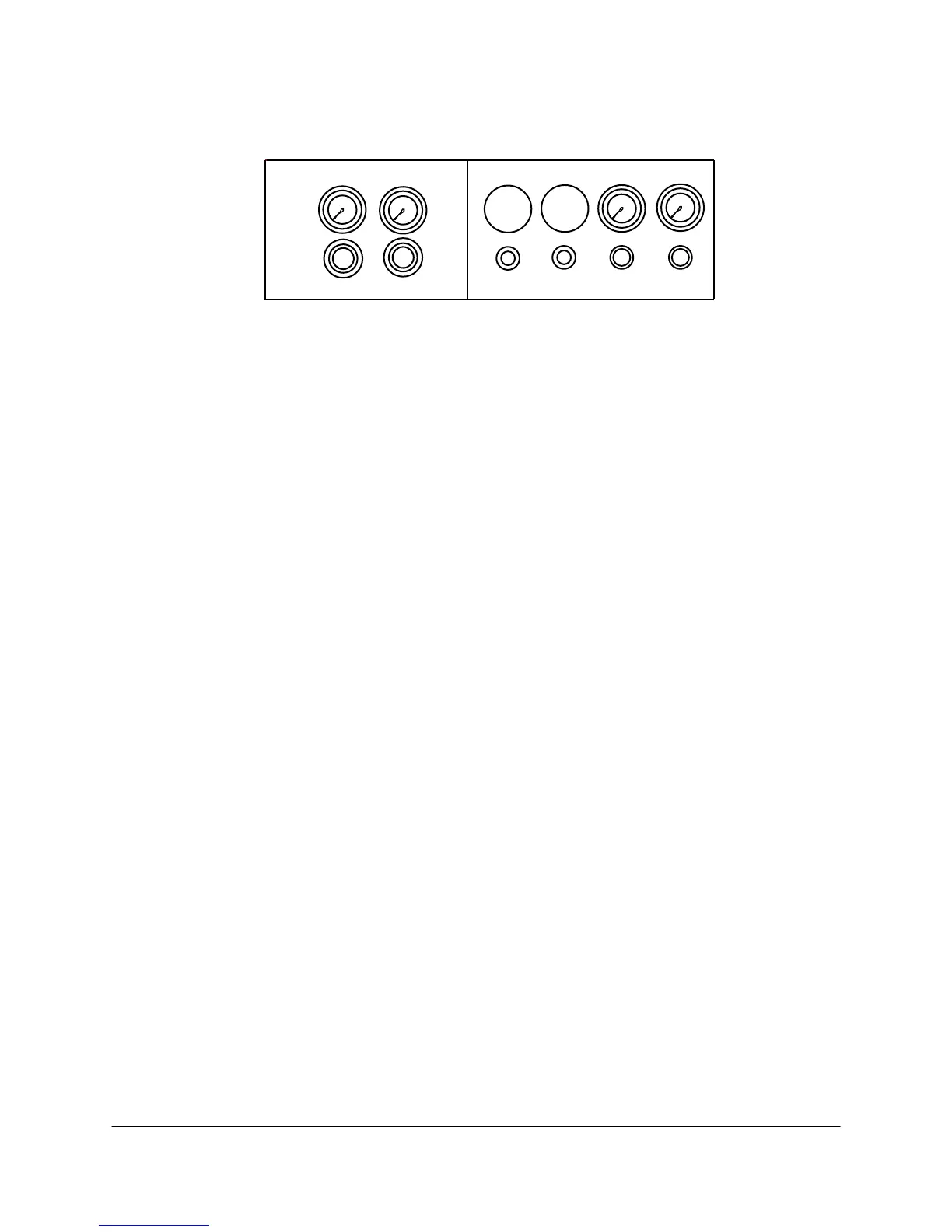

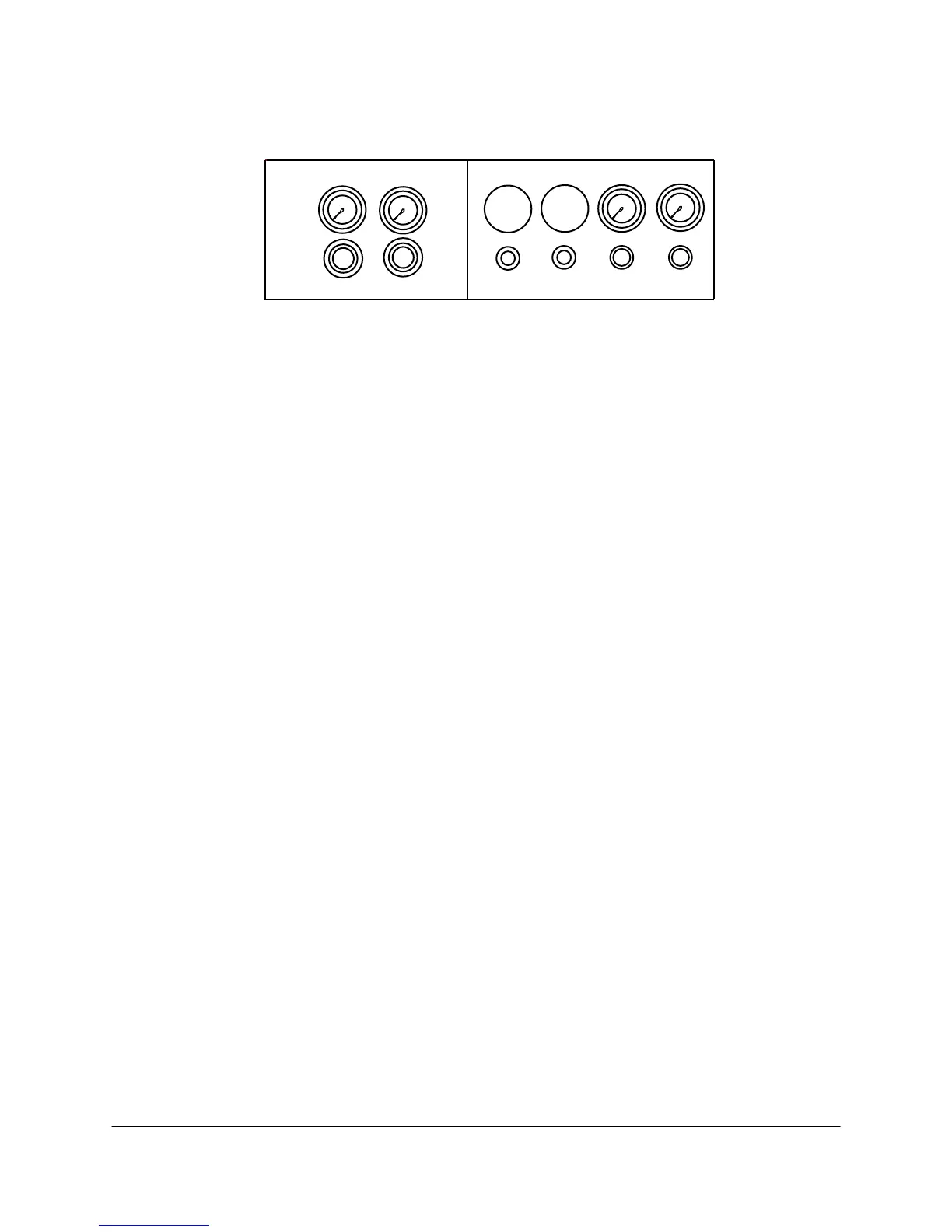

5. Refer to Figure 2-4 (when EPC is installed, the Pressure Control Panel will be blank). The purge

air and heater air pressures should be as specified on the label below the corresponding

regulator.

Purge Air Panel Pressure Control Panel

Figure 2-4. ANALYZER ADJUSTMENTS

6. Turn on carrier gas at its source.

7. Refer to the Data Package to ensure that the specified carrier gas is provided at the specified

pressure to each CARRIER inlet.

8. At the external circuit breaker or switch turn the power ON.

9. For EPC-equipped analyzers, refer to the Manual Pressure Control Mode screen. Verify that

carrier and gas pressures are the same as those specified in the Data Package. If necessary,

adjust each set point (SP) until it is the same as the Data Package value.

10. If the analyzer has mechanical regulators, verify from the Pressure Control Panel gauge that

carrier and pressures are the same as that specified in the Data Package. If necessary, adjust

each regulator until its gauge value is the same as the Data Package value.

11. Verify any other gases in the same manner as Carrier #1.

12. If a leak occurs during start-up, perform the leak check described in "Leak Check."

13. Allow sufficient time for oven warm-up. The oven should stabilize at the temperature indicated in

the Data Package. If adjustments are required, adjust the Digital Temperature Controller as

described in "DIGITAL TEMPERATURE CONTROLLER" in Section 4.

14. Proceed to "MATCHING COLUMN FLOWS."

Leak Check

If a leak occurs during initial turn-on, perform a simple leak check on the analyzer section as follows:

1. Plug all carrier gas vents and pressurize to 30 psig. Shut off the carrier supply.

2. Note pressure drop-off on the carrier supply and column pressure gauges. A visual decline is

excessive.

3. Starting at the inlet to the detector and working back to the carrier gas supply, plug the exit of

each valve or column to locate the leak.

4. Use “Snoop®“ or other suitable leak detection solution to check for leaks.

Loading...

Loading...