66 Rockwell Automation Publication 193-UM015E-EN-P - October 2015

Chapter 2 Installation and Wiring

Control Circuits

The E300 relay can provide motor control logic for many different types of

motor starters (see Chapter 5

for more information on Operating Modes). By

default, the E300 relay is configured for the Overload-Network operating mode.

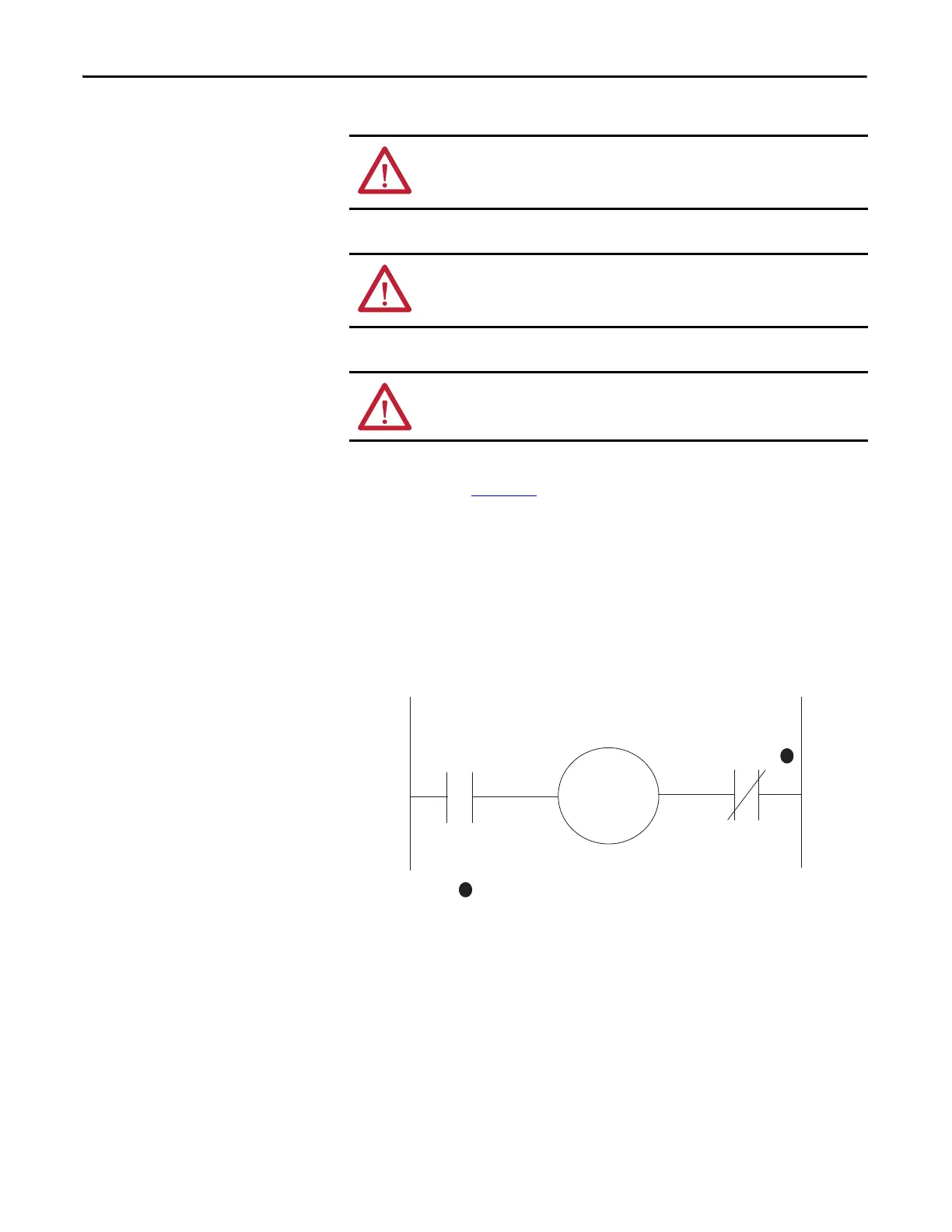

The following wiring diagrams are typical control circuits for Non-Reversing and

Reversing Motor starters that use the Overload-Network operating mode when

Relay 0 (terminals R03 and R04) is configured to be a normally closed Trip Relay.

Full-voltage Non-reversing Starter (with Network Control)

Figure 50 - NEMA Nomenclature

ATTENTION: Do not exceed the ratings of the E300 relay’s output and trip relay.

If the coil current or voltage of the contactor exceeds the overload relay’s

ratings, an interposing relay must be used.

ATTENTION: When the power is applied to the E300 relay’s A1 and A2

terminals, the N.O. relay contact that is assigned as a Trip Relay closes after

approximately 2 seconds if no trip condition exists.

ATTENTION: More control circuit protection may be required. See the

applicable electrical codes.

Relay 1

Relay 0

Configured as a

Trip Relay

R13 R14

A1

A2

M

R03

R04

1

1

Contact shown with supply voltage applied.