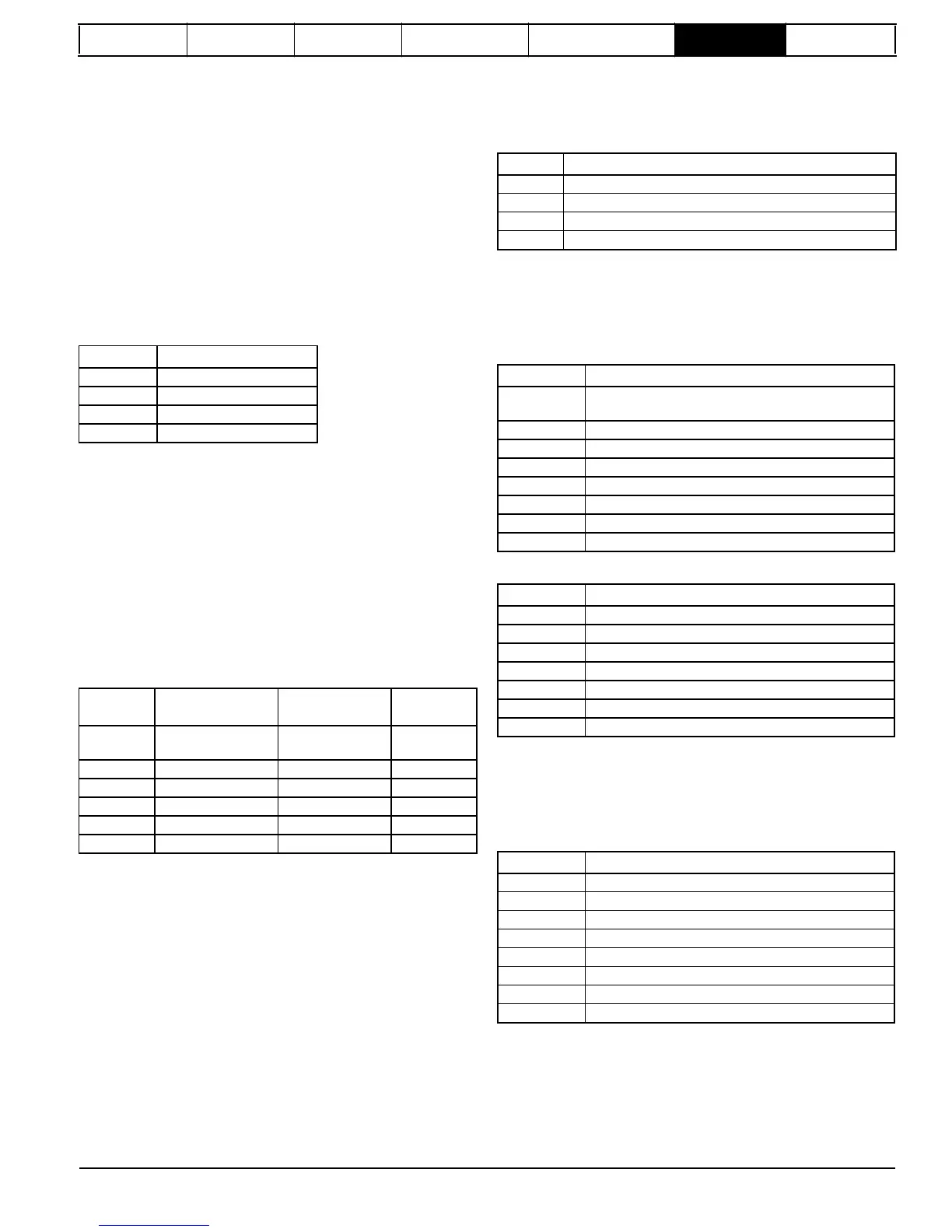

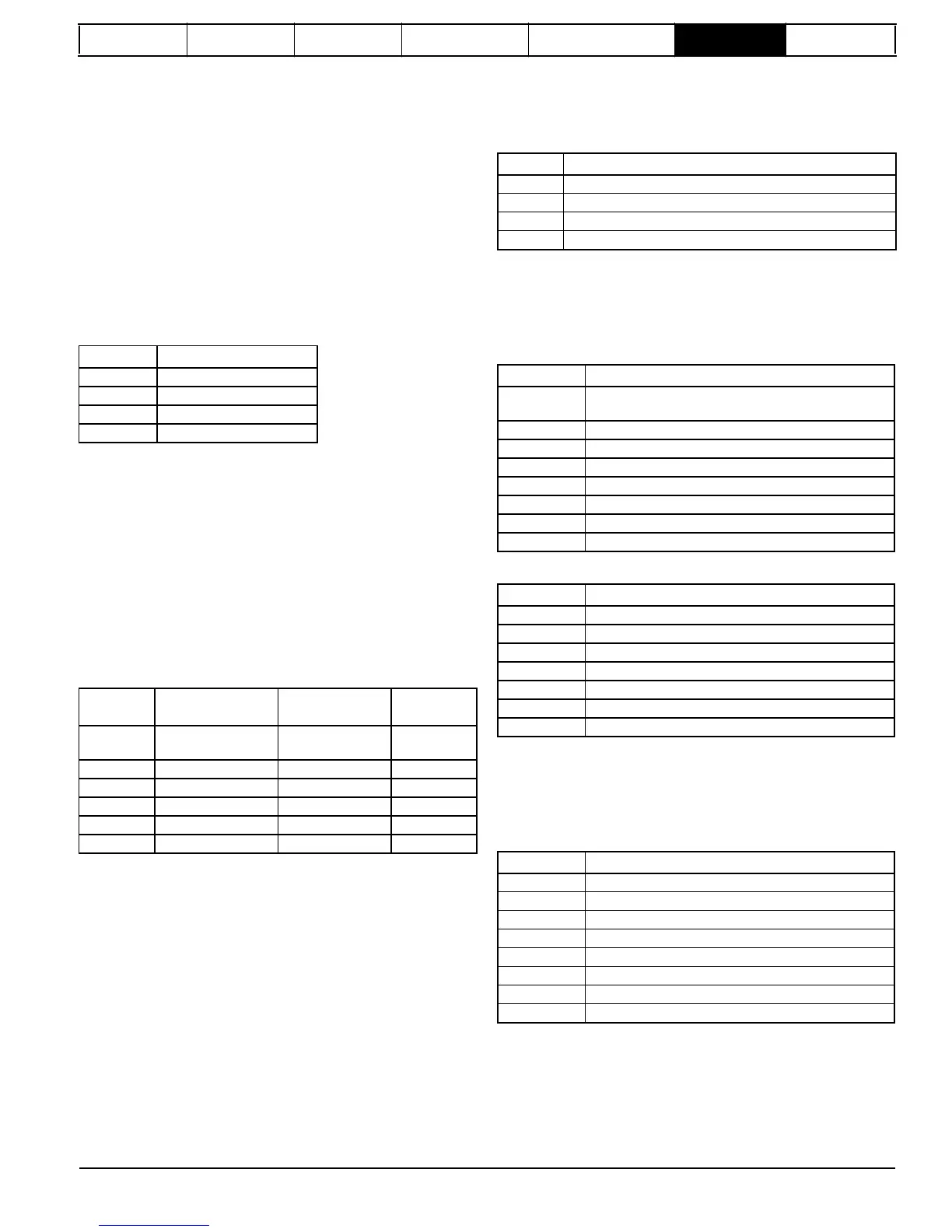

format

Advanced parameter

descriptions

Serial

comms

6.2.2

Slave

address

The first byte of the frame is the slave node address. Valid slave node

addresses are 1 through 247 decimal. In the master request this byte

indicates the target slave node; in the slave response this byte indicates

the address of the slave sending the response.

Global

addressing

Address zero addresses all slave nodes on the network. Slave nodes

suppress the response messages for broadcast requests.

6.2.3

MODBUS

registers

The MODBUS register address range is 16bit (65536 registers) which at

the protocol level is represented by indexes 0 through 65535.

PLC

registers

Modicon PLCs typically define 4 register 'files' each containing 65536

registers. Traditionally, the registers are referenced 1 through 65536

rather than 0 through 65535. The register address is therefore

register files can be considered to map onto a single register address

space. However, specific function codes are defined in MODBUS to

support access to the "coil" registers.

All standard CT drive parameters are mapped to register file '4' and the

coil function codes are not required.

CT

parameter

mapping

All CT products are parameterized using the #menu.param notation.

Indexes 'menu' and 'param' are in the range 0 through 99. The

#menu.param is mapped into the MODBUS register space as menu*100

+ param.

To correctly map the parameters at the application layer, the slave

device increments the received register address. The consequence of

6.2.6

Function

codes

The function code determines the context and format of the message

data. Bit 7 of the function code is used in the slave response to indicate

an exception.

FC03

Read

multiple

Read a contiguous array of registers. The slave imposes an upper limit

on the number of registers, which can be read. If this is exceeded the

slave will issue an exception code 2.

Writes a value to a single 16bit register. The normal response is an echo

of the request, returned after the register contents have been written.

The register address can correspond to a 32bit parameter but only 16

bits of data can be sent.

The MODBUS protocol specification defines registers as 16bit signed

integers. All CT devices support this data size.

Refer to the section 6.2.7 Extended data types on page 208 for detail on

accessing 32bit register data.

6.2.4

Data

consistency

All CT devices support a minimum data consistency of one parameter

(16bit or 32bit data). Some devices support consistency for a complete

multiple register transaction.

6.2.5

Data

encoding

MODBUS RTU uses a 'big-endian' representation for addresses and

data items (except the CRC, which is 'little-endian'). This means that

when a numerical quantity larger than a single byte is transmitted, the

MOST significant byte is sent first. So for example

16 - bits

0x1234

would be

0x12

0x34

32 - bits

0x12345678

would be

0x12

0x34

0x56

0x78

Mentor MP Advanced User Guide

207

Issue Number: 4

www.onxcontrol.com

Byte

Loading...

Loading...