Parameter

structure

Keypad and

format

Advanced

parameter

descriptions

Serial comms

speed reference is enabled). If the drive is disabled this parameter will show 0.0.

as selected with Pr

3.26

{

Fb01,

0.71

}. Pr

3.02

{

di05,

0.40

} shows the level of the speed feedback selected for the speed controller. Display filtering is

active when this parameter is viewed with one of the drive keypads. The value held in the drive parameter (accessible via comms or an Solutions

Module) does not include this filter, but is a value that is obtained over a sliding 16 ms period to limit the ripple seen in this parameter value. The

speed feedback value includes encoder quantization ripple given by the following equation:

Ripple in Pr

3.02

{

Fb01,

0.71

} = 60 / 16 ms / (ELPR x 4)

The

16

ms

sliding

window

filter

is

always

applied

to

the

value

shown

in

Pr

3.02

{Fb01,

0.71},

but

this

sliding

window

filter

is

not

normally

applied

to

the

actual

speed

feedback

used

by

the

speed

controller

or

the

drive

encoder

reference

system

(Pr

3.43

to

Pr

3.46).

The user may

apply a filter to the speed controller input and the drive encoder reference system input if required by setting Pr

3.42

to the required filter time. The

encoder ripple seen by the speed controller is given by:

Encoder speed ripple = 60 / Filter time / (ELPR x 4)

If Pr

3.42

is set to zero (no filter) the ripple seen by the speed controller and drive encoder reference system is given by:

Encoder speed ripple = 60 / 250 µs / (ELPR x 4)

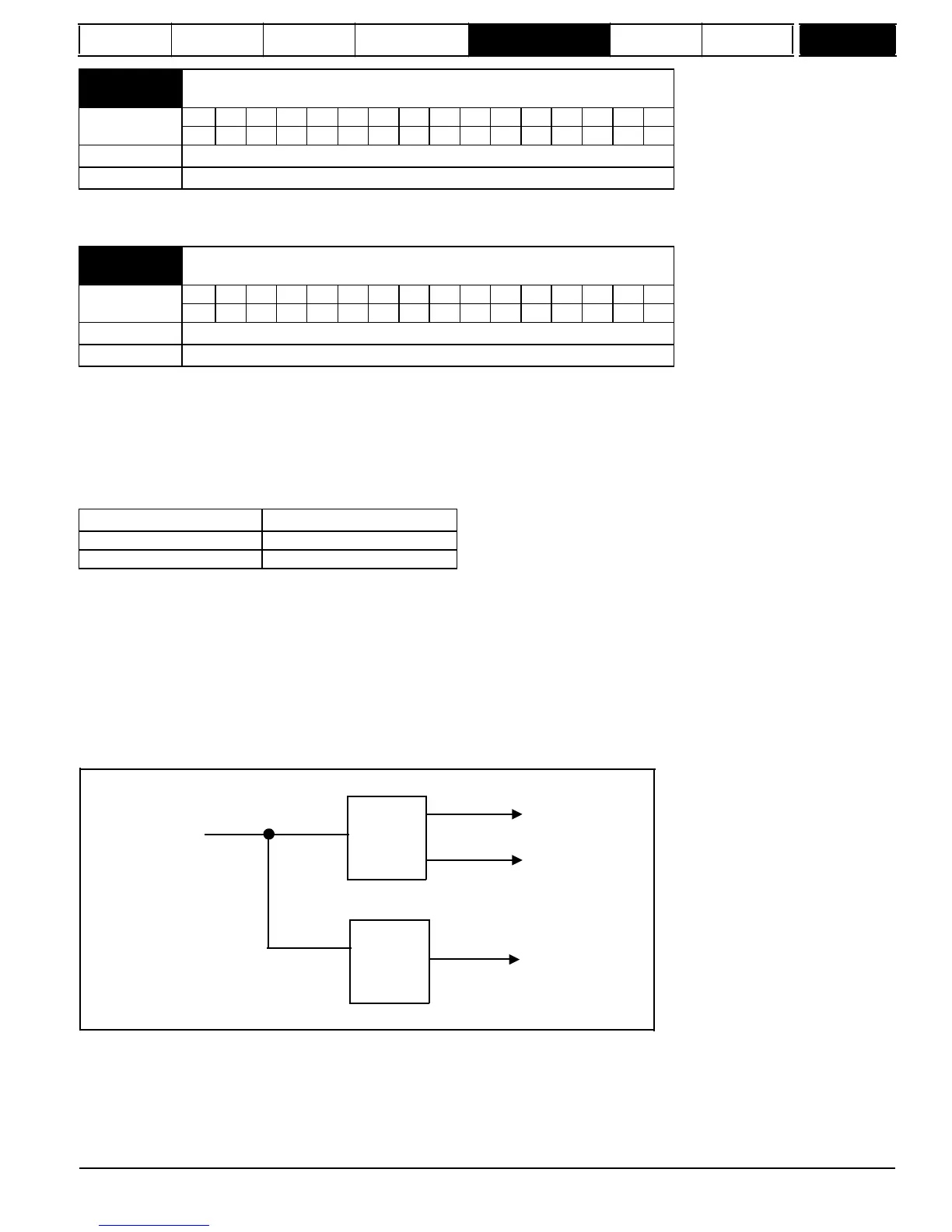

From the drive

encoder port

Filter

defined

by Pr

3.42

16ms

filter

Speed

controller

Drive encoder

reference

system

Pr

3.02

and

Pr

3.27

The diagram above shows the filter arrangement. It should be noted that the same filtering is provided at the speed controller input and for Pr

3.02

{

di05,

0.40

} when the feedback is obtained from an Solutions Module, but the variable length window filter is controlled by Pr

x.19

.

It is not advisable to set the speed feedback filter too high unless it is specifically required for high inertia applications with high controller gains

because the filter has a non-linear transfer function. It is preferable to use the current demand filters (see Pr

4.12

or Pr

4.23

) as these are linear first

order filters that provide filtering on noise generated from both the speed reference and the speed feedback. It should be noted that any filtering

included within the speed controller feedback loop, either on the speed feedback or the current demand, introduces a delay and limits the maximum

bandwidth of the controller for stable operation.

Mentor MP Advanced User Guide

43

Issue Number: 4

www.onxcontrol.com

3.01

Loading...

Loading...