P/N 960-100189RA_Rev. A {EDP #148850} © 2009, Japan CashMachine Co., Limited

Calibration and Testing VEGA™ Series BankNote Validator Section 6

10. Once the White Reference Paper adjustment of

the Validation Sensor is complete, the Front

Panel LED will slowly blink at a Blue Color rate.

11. Make sure the adjustment is complete by verify-

ing the Blue

LED blink rate, and remove the

White Reference Paper from the Transport

Section. To remove the White Reference Paper,

rev

erse the paper loading procedure described in

Reference Paper Usage

on page 6-5

of this

Section.

12. Set the Black Reference Paper in place (

See Ref-

erence Paper Usage

on page 6-5

of this Section).

13. Set DIP Switch Block No. 2, Switch #3 ON.

This action performs the Validation Sensor’s

adjus

tments using the Black Reference Paper.

(Keep DIP Switch Block No.2, Switches #1, #2

& #3 ON until receiving Screen instruction to

turn them OFF).

14. Once the Black Reference Paper adjustment of

the

Validation Sensors are complete, the Front

Panel LED will slowly blink at a Purple Color

rate.

15. Make sure the adjustment is complete by verify-

ing the Pu

rple LED blink rate, and remove the

Black Reference Paper from the Transport

Section. To remove the Black Reference Paper,

rev

erse the paper loading procedure described in

Reference Paper Usage

on page 6-5

of this Sec-

tion.

16. Set DIP Switch Block No. 2, Switch #4 ON.

This action re-performs the Validation Sensor’s

Non-Paper adjustment. (Keep DIP Switch Block

No.

2, Switches #1, #2, #3 & #4 ON until

receiving a Screen instruction

to turn them OFF).

17. Once the Validation Sensor’s Non-Paper adjust-

ment is complete, the Front Panel LED will

slowly blink at a Gr

een Color rate.

18. Set DIP Switch Block No. 2, Switch #5 ON.

This action performs the Edge Sensor’s Non-

Pap

er adjustment. (Keep DIP Switch Block No.

2, Switches #1, #2, #3, #4 & #5 ON until receiv-

ing a Screen instruction t

o turn them OFF).

19. Once the Edge Sensor’s non-paper adjustment is

compl

ete, the Front Panel LED will slowly blink

at a Yel lo w Color rate.

20. Set DIP Switch Block No. 2, Switches #1, #2, #3,

$4

& #5 OFF to write these adjustment result into

the VEGA Unit’s EEPROM Memory.

21. Once the data writing procedure is complete, the

Front Panel LED will blink at a Green Color

rate.

22. Turn the VEGA Units power switch OFF.

This completes the Calibration Paper adjustment

Procedure.

Performance Tests

The VEGA Unit provides Self-diagnostic Perfor-

mance Tests to be performed by the User. The

following content information provides a summary

of

the VEGA Performance Tests available for use.

P

ERFORMANCE

T

EST

P

REPARATION

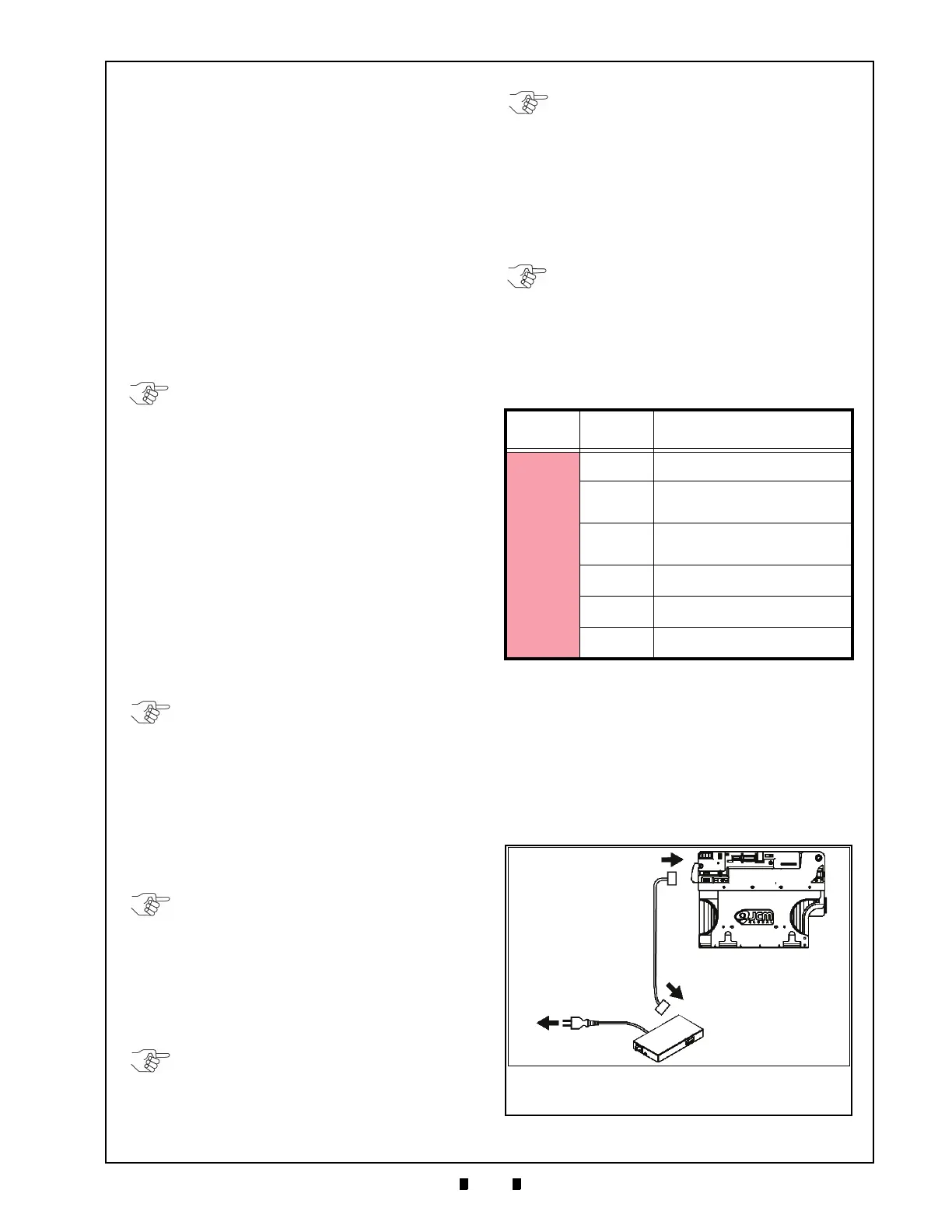

Figure 6-83 illustrates the VEGA Tool and Harness

Cable interconnections required to perform these

pro

cedures.

NOTE: While the adjustment process is

active, the Blue LED will momentarily flash

at high rate of speed.

NOTE: While the adjustment process is

active, the Front Panel LED will flash a

Purple Color at a high rate of speed.

NOTE: During the adjustment process, the

Front Panel LED will flash a Green Color at

a high rate of speed.

NOTE: While writing the data to EEPROM,

the Front Panel LED will flash a Yellow

Color at a high of rate speed.

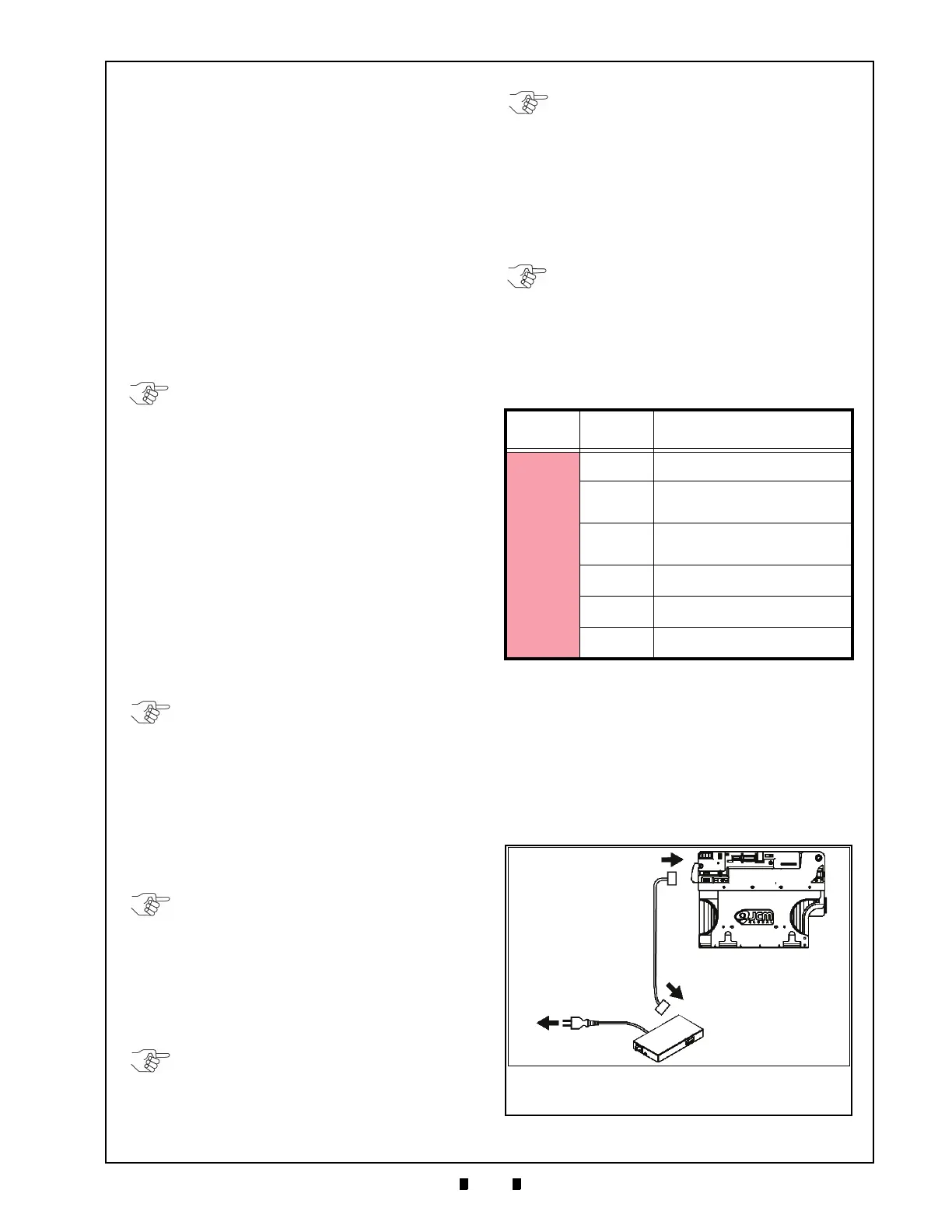

Table 6-1 Red Blink Rate Error

LED Colors

Blink

Sequenc

e

Error Indication

Red

1 Blink

The Entrance Sensor adjustment has

failed.

2 Blinks

The Entrance Sensor adjustment

using White Reference Paper has

failed.

3 Blinks

The Validation Sensor adjustement

using Black Reference Paper has

failed.

4 Blinks

The Validation Sensor’s Non-Paper

adjustment has failed.

5 Blinks

The Edge Sensor adjustment has

failed.

6 Blinks

The EEPROM data writing process

has failed.

NOTE: If EEPROM data writing fails, all

previous adjustment data will be lost which

may disable performance of the VEGA

Unit!

NOTE: If the adjustment of ANY Sensor

fails, the Front Panel LED will blink RED.

If this error occurs, ensure that the

procedures were correctly performed, and

then re-perform them again. Refer to Table

6-1 for detail explanations of each RED

Color Blink sequence indication.

Figure 6-83 Tool and Harness Interconnections

Interface Connector

Power Supply

To A C Po w e r

c

a

b

Receptacle

a) VEGA Unit

b) Power Supply (e.g., UAC, MIB232, etc)

c) Harness

Loading...

Loading...