.

OPERATION

OPERATION

ADJUSTING BRACE

WARNING

If maintenance is carried out with the engine running, always have one worker sitting in the operator's seat while another worker

carries out the maintenance. Both workers must mutually confirm the safety during the operation.

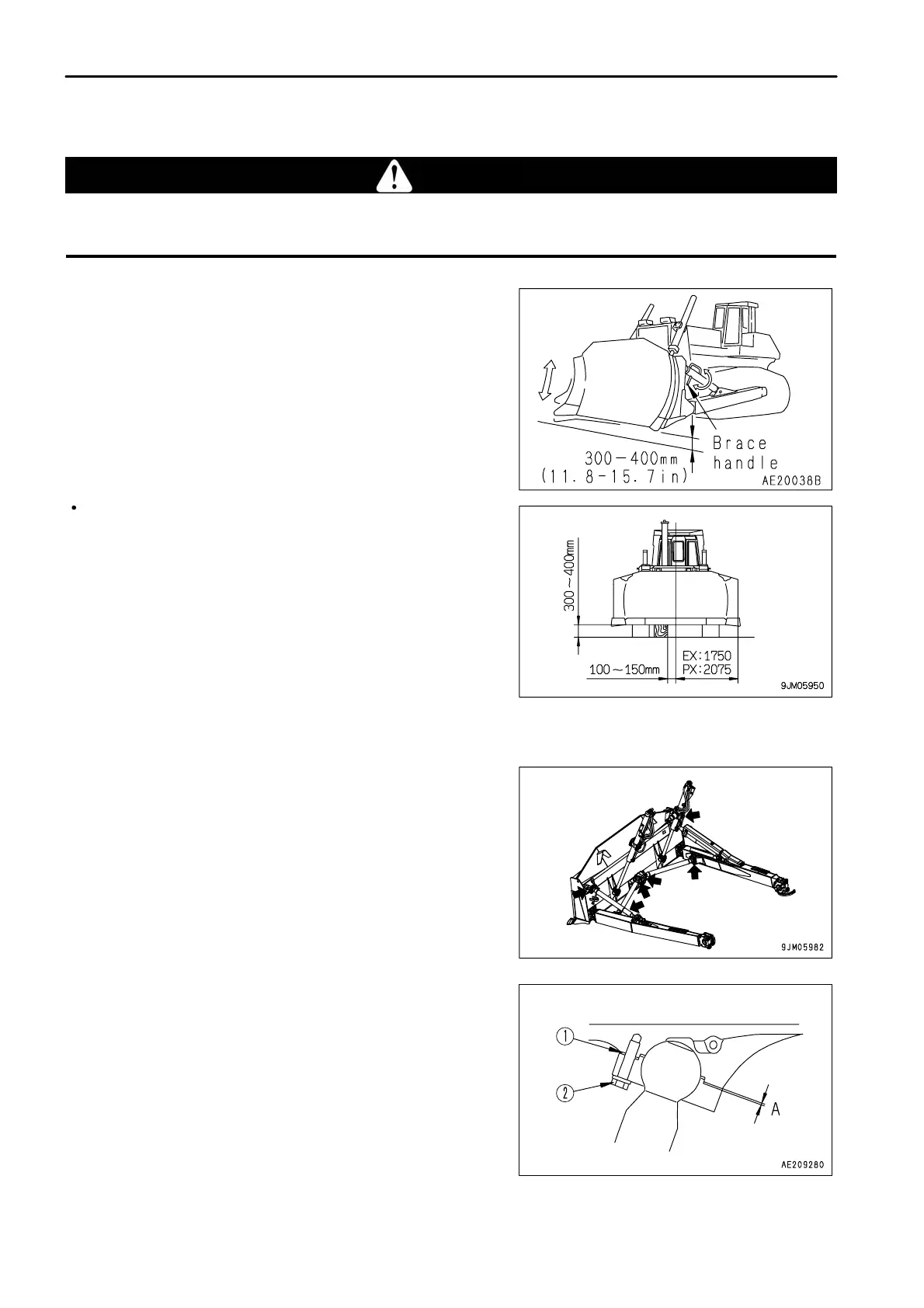

Start the engine, then use fine operation of the blade control lever

to tilt to the left and right. Move the blade up and down while

rotating the brace handle. This makes the adjustment operation

easier.

When extending the brace

It is easy to carry out the adjustment if the blade is set on top of a

block and the brace handle is turned.

REMARK

When operated in this way, the blade is tilted, so the handle

gradually becomes heavier. When this happens, return the blade

from the tilt position to the horizontal position and turn the handle

again according to the procedure given above.

SHIM ADJUSTMENT

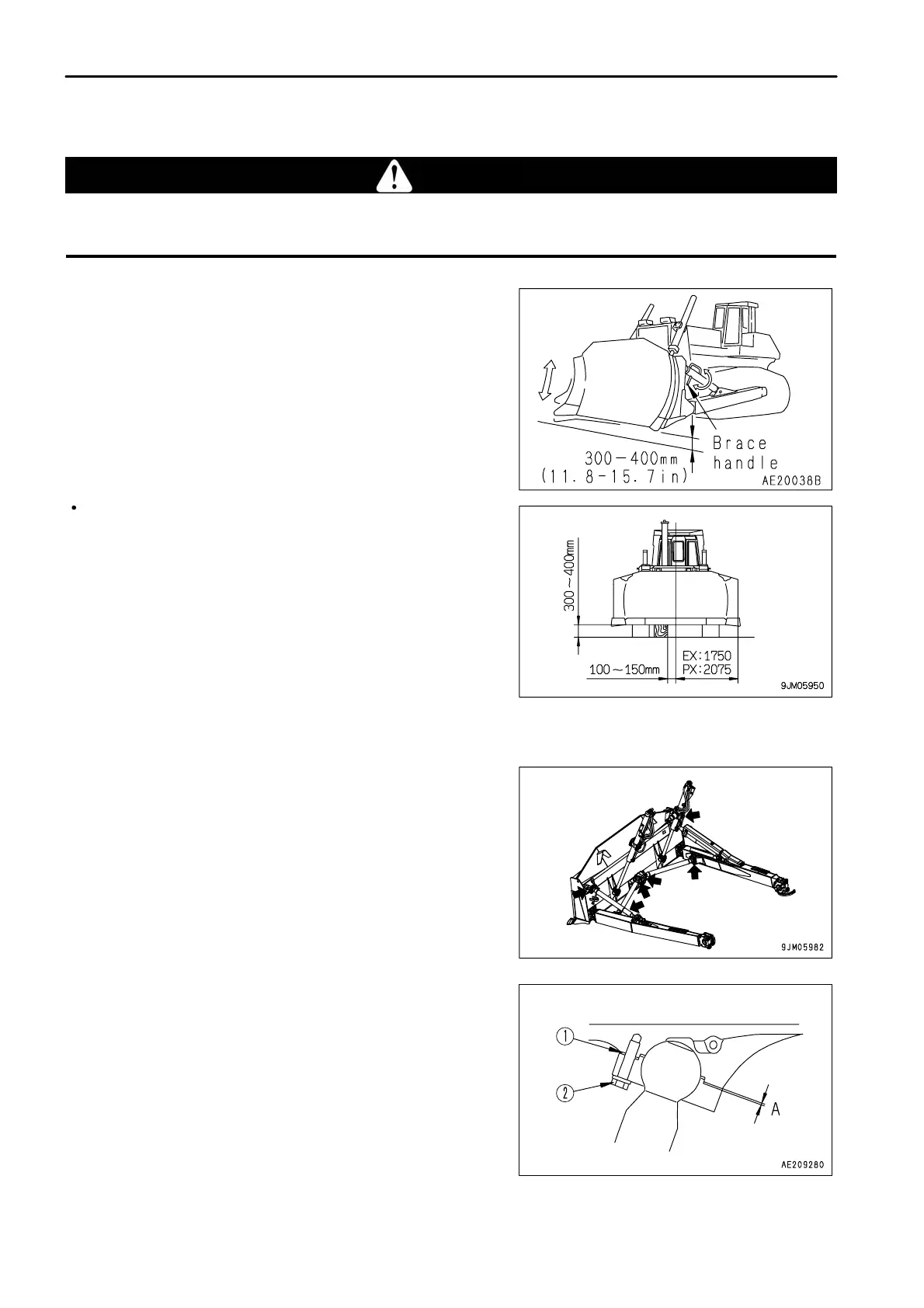

Adjust the thickness of shim so that the ball joint play (6 points) in

the axial direction (shown by the arrow) does not exceed 1 mm

(0.04 in).

1. Remove shim (1) and tighten bolts (2) to eliminate the ball joint

play.

2.

Measure clearance "A" and remove bolts (2).

3. Adjust the thickness of shim (1) to (A + 0.5) - (A + 1) mm, then

tighten bolt (2).

4.

Confirm that ball joint can move smoothly after tightening bolts.

3 - 122

Loading...

Loading...