.

MAINTENANCE

SERVICE PROCEDURE

EVERY 250 HOURS SERVICE

LUBRICATING

1. Lower the work equipment to the ground, then stop the engine.

2.

Using a grease pump, pump in grease through the grease fittings shown by arrows.

3.

After greasing, wipe off any old grease that was pushed out.

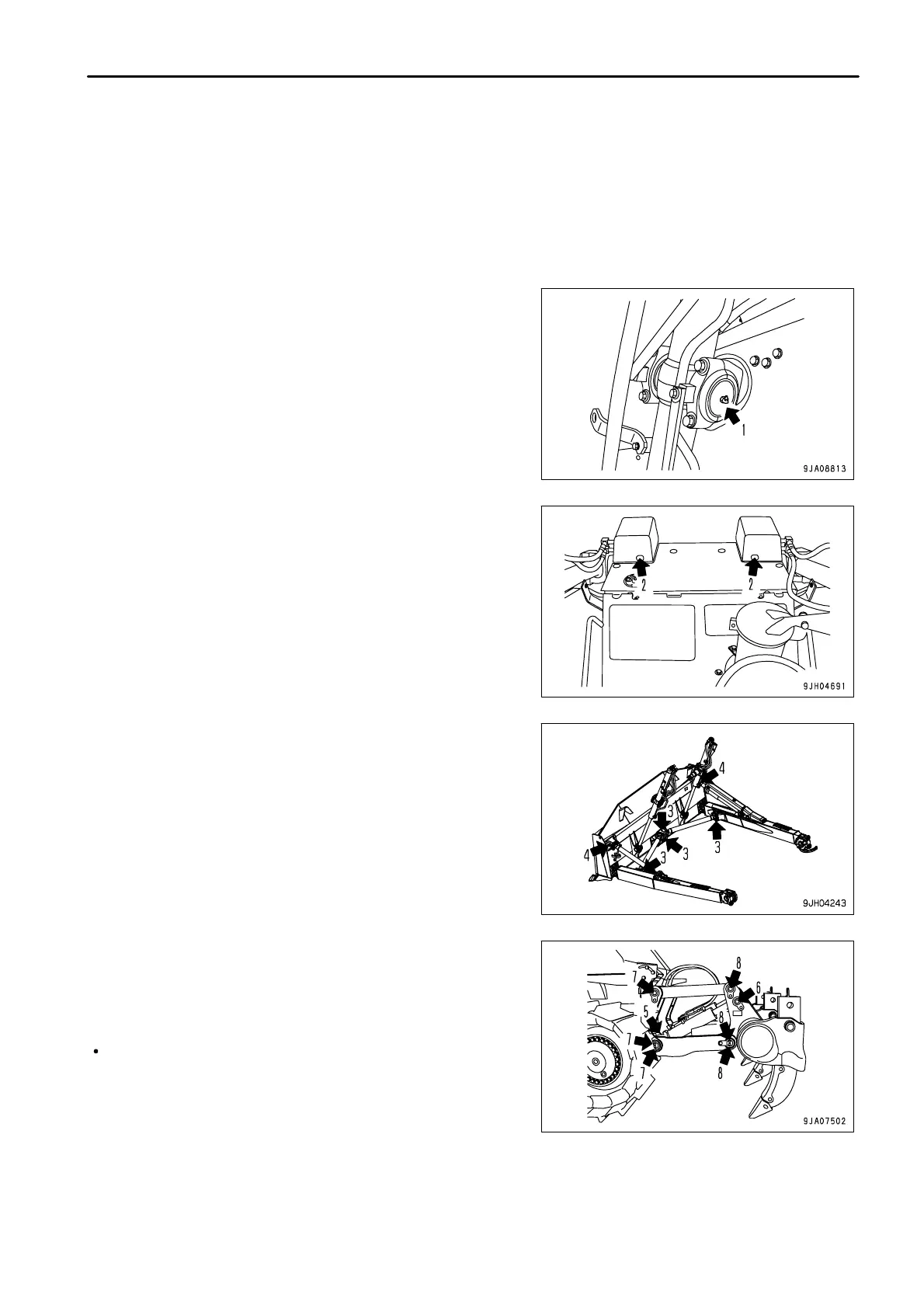

(1) Blade lift cylinder support yoke (4 places)

REMARK

These are at the front and rear of the left and right cylinders.

(2) Blade lift cylinder support shaft (2 places)

(3) Blade arm ball joint (4 places)

(4) Brace screw (2 places)

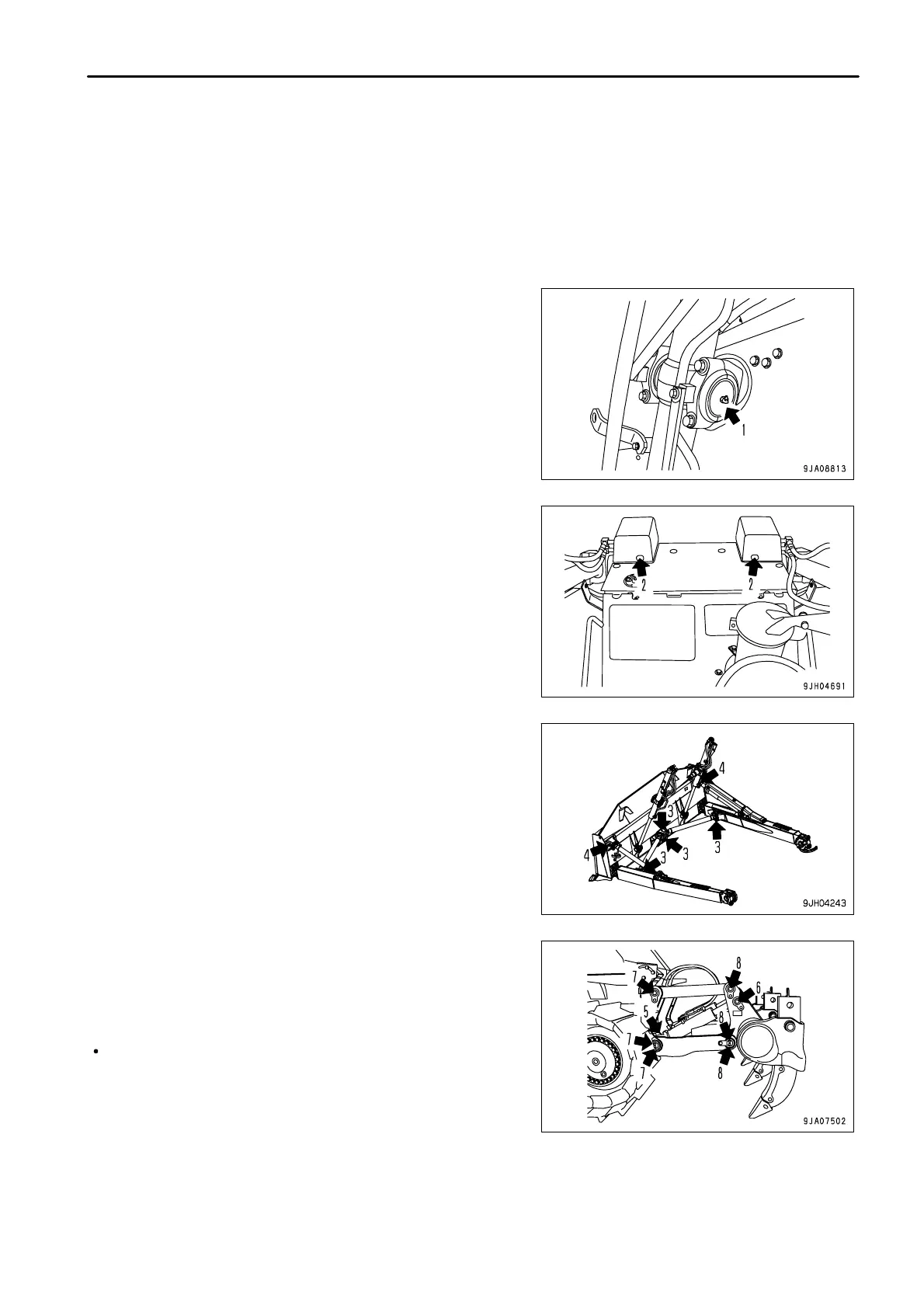

(5) Ripper lift cylinder bottom pin (2 places)

(6) Ripper lift cylinder rod end pin (2 places)

(7) Ripper arm pin (front) (6 places)

(8) Ripper arm pin (rear) (6 places)

(5) - (8) indicate the greasing points for the fixed multi-shank

ripper specification.

4 - 45

Loading...

Loading...