.

MAINTENANCE

SERVICE PROCEDURE

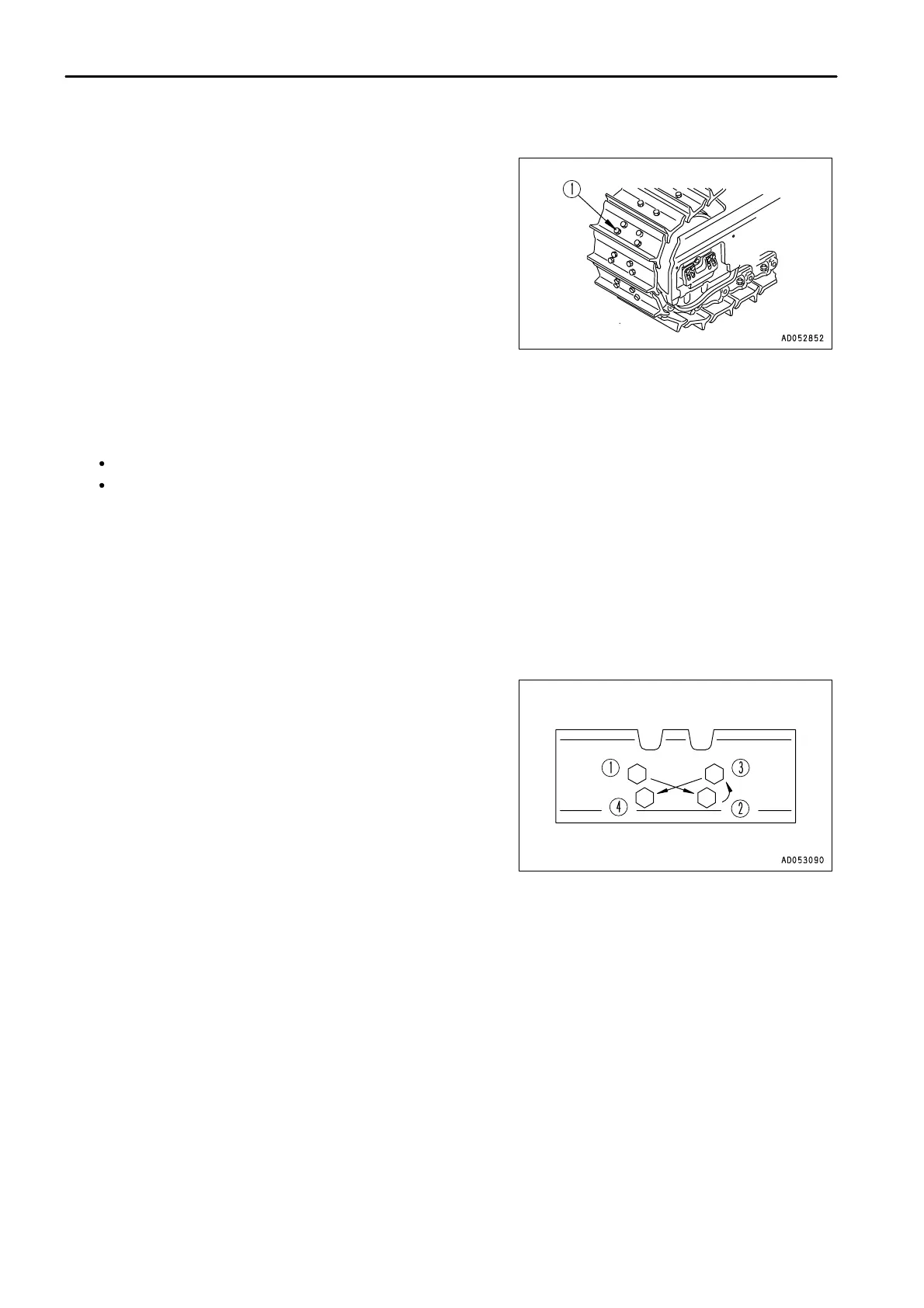

CHECK AND TIGHTEN TRACK SHOE BOLTS

If the machine is used with track shoe bolts (1) loose, they will

break, so tighten any loose bolts immediately.

METHOD OF TIGHTENING SHOE BOLT

1.

First, tighten to the tightening torque below, then check that the nut and shoe are in close contact with the link

mating surface.

D85EX: 343 ± 39 Nm (35 ± 4 kgm, 253.2 ± 28.9 lbft)

D85PX: 539 ± 49 Nm (55 ± 5 kgm, 253.2 ± 28.9 lbft)

2.

After checking, tighten a further 120° ± 10°.

METHOD OF TIGHTENING MASTER LINK CONNECTING BOLT

1.

First tighten to a tightening torque of 343 ± 39 Nm (35 ± 4 kgm, 253 ± 29 lbft) then check that the link contact

surfaces are in close contact.

2.

After checking, tighten a further 160° to 180°.

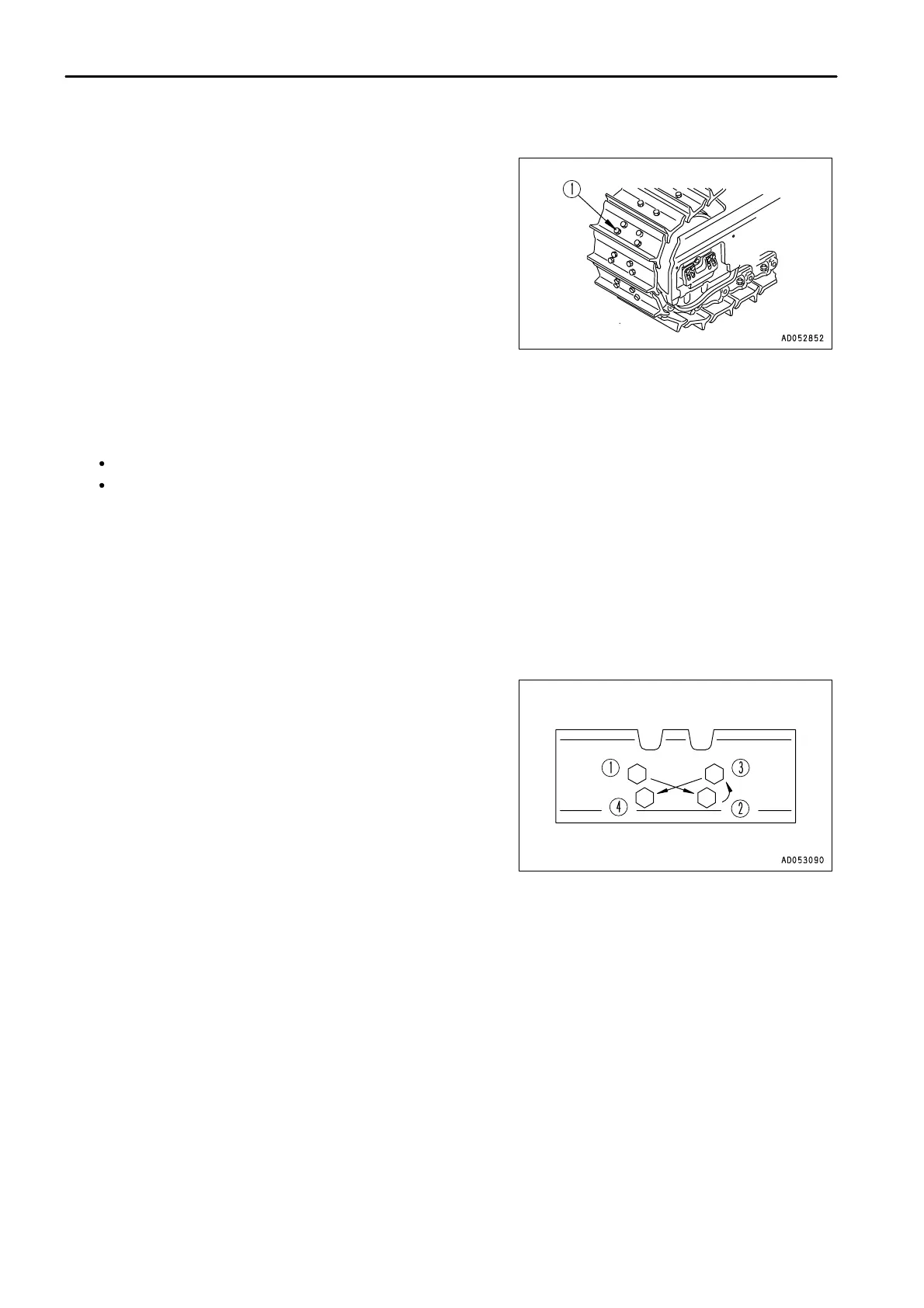

ORDER FOR TIGHTENING

Tighten the bolts in the order shown in the diagram on the right.

4 - 30

Loading...

Loading...