.

MAINTENANCE

SERVICE PROCEDURE

REVERSE AND REPLACE THE END BITS AND CUTTING EDGES

WARNING

It is dangerous if the work equipment moves by mistake when the cutting edges and end bits are being reversed or replaced.

Set the work equipment in a stable condition, then stop the engine and lock the blade control lever securely with the work

equipment lock lever.

Reverse or replace the end bits and cutting edges before it is worn out to the blade end.

1. Raise the blade to a proper height, position a block under the frame to prevent the blade from falling.

2.

Operate the work equipment lock lever to the LOCK position.

If the cutting edge and the end bit on both sides are worn out, replace with new one.

If the mounting surface is worn, correct it before turning or replacing the end bits.

3.

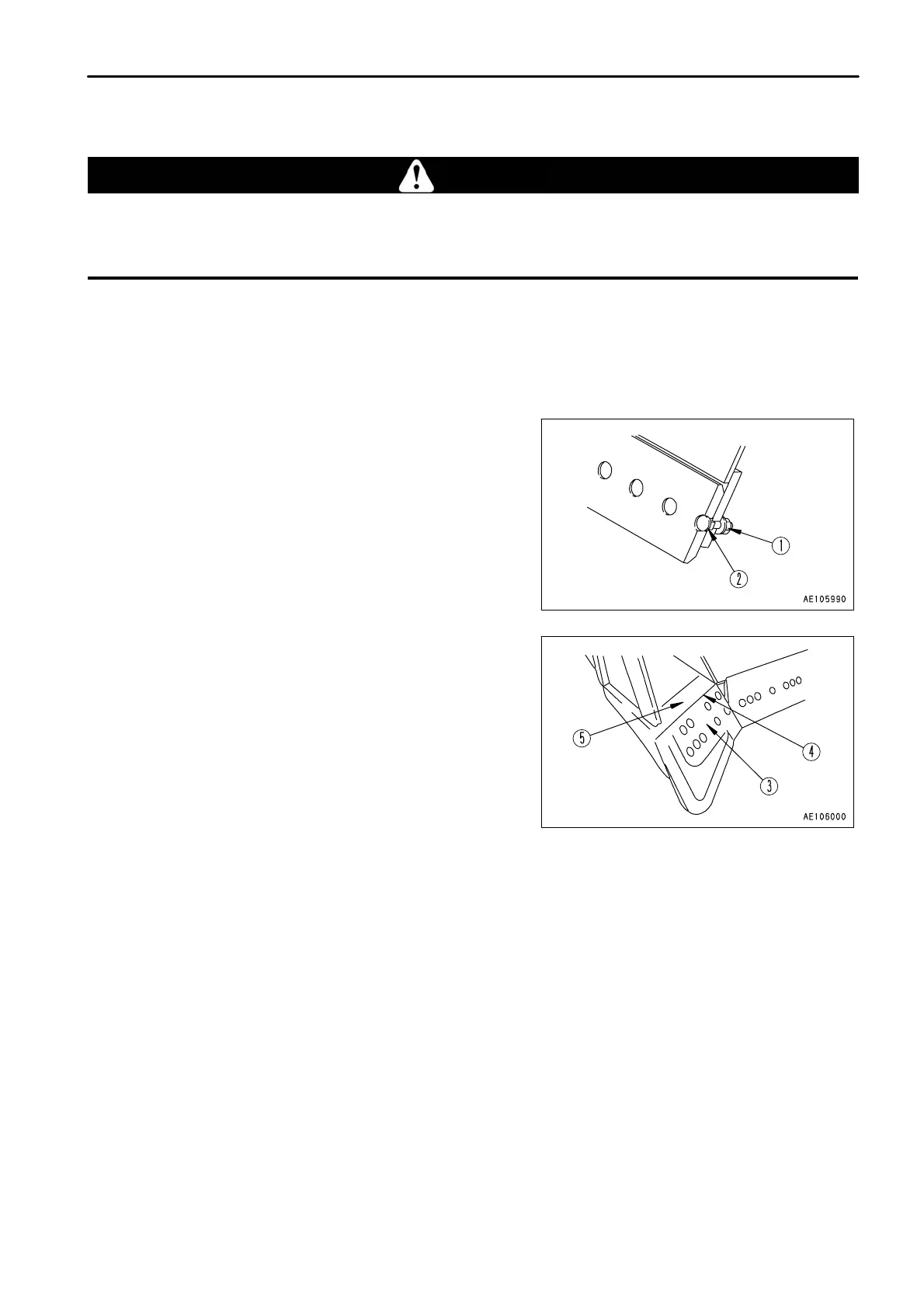

Loosen nut (1) and remove bolt (2). Then remove the cutting

edge and the end bit and clean the mounting surface.

4. Reverse or replace the cutting edge and the end bit when worn

out.

If bolt (1) and nut (2) are damaged, replace them with new ones

at the same time.

5.

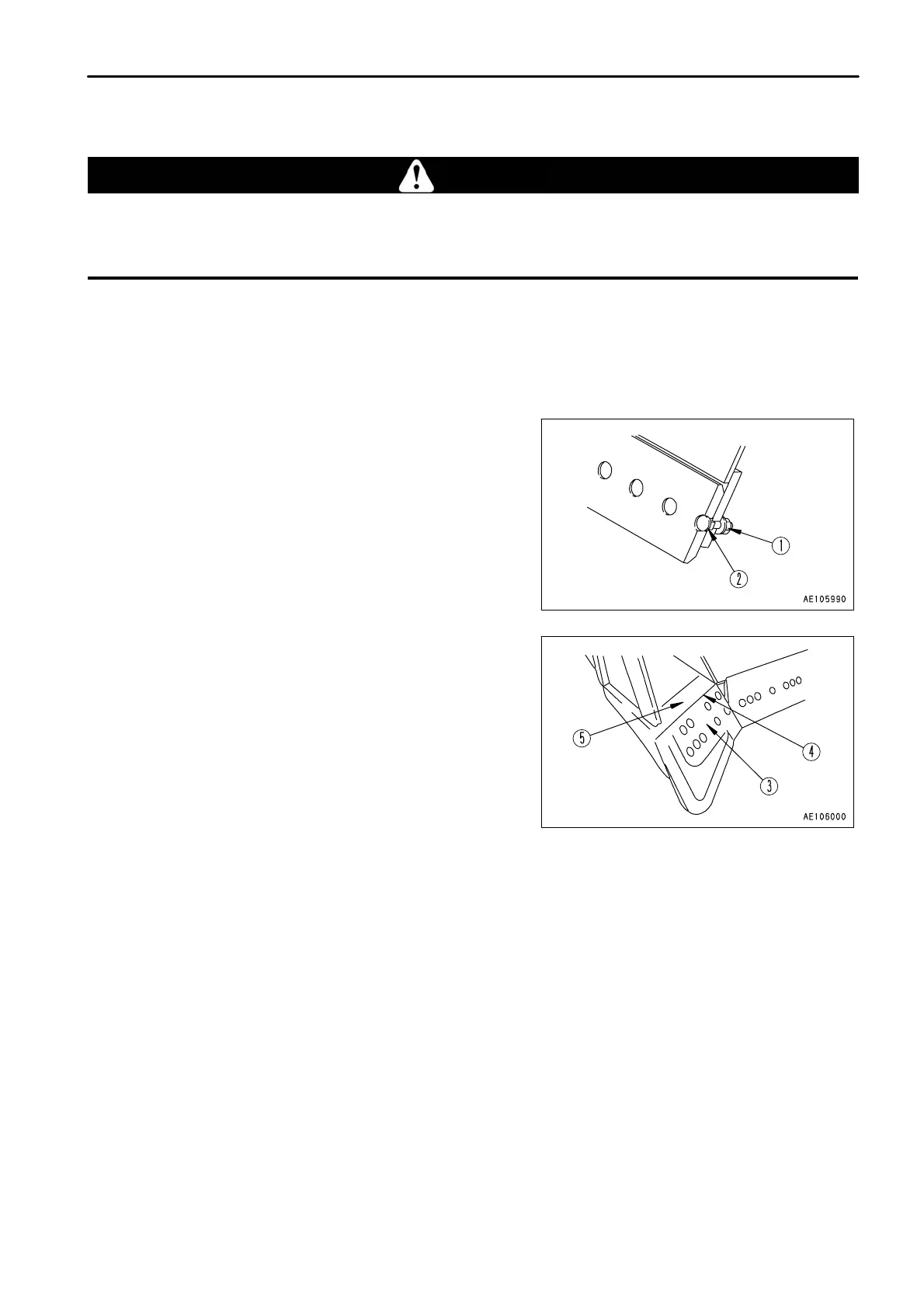

Install the edge to the blade, then tighten partially. Drop the

blade three to five times on to the ground or rock to remove any

play in bolt (2), then tighten it to the correct tightening torque.

When installing end bit (3), put top surface (4) of the end bit in

close contact with stopper (5), then tighten with the bolts.

Tightening torque: 628 ± 79 Nm (64 ± 8 kgm, 462 ± 57.9 lbft)

6. After several hours of running, retourque the nuts.

4 - 33

Loading...

Loading...