.

OPERATION

OPERATION

INSPECTION AND REPAIR

Frequent inspection and prompt repair will reduce repair costs.

The following items for inspection will serve as a guide to maintenance service of each undercarriage part. Perform

periodical inspection and contact the Komatsu distributor in your area when machine has approached repairable

limits and reversing limits.

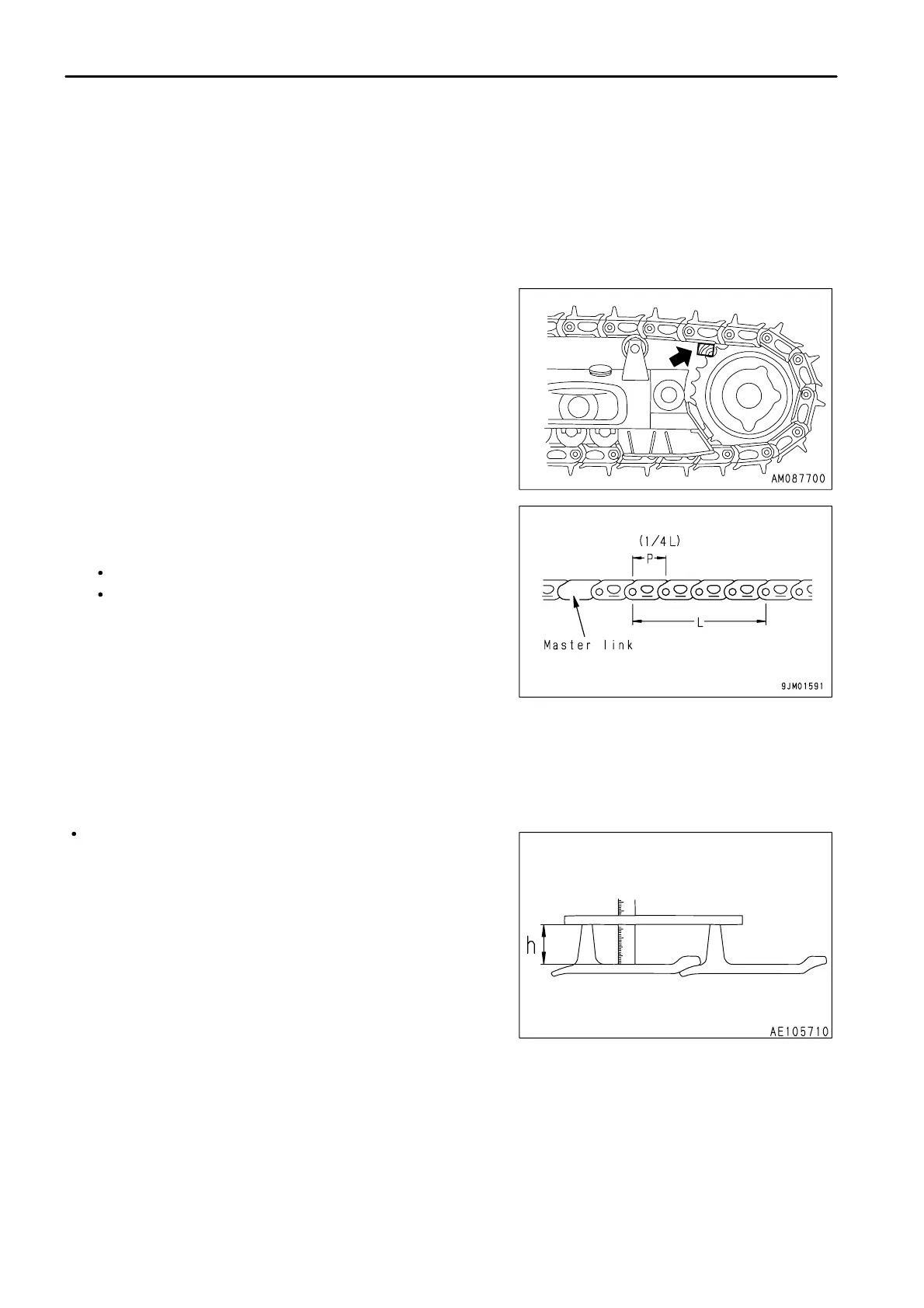

MEASURING LINK PITCH

1.

Insert a wooden block between track shoe and sprocket to take

up the slack in track shoes.

2.

Measure pitch length of 4 links in stretched portion at least 2

links away for master pin. Of length obtained, 1/4 is the link

pitch.

Basic link pitch (P): 216.3 mm (8.5 in)

Link pitch limit for turning bushing: 219.3 mm (8.6 in)

There is no link window on the master link.

REMARK

The measured value under decimal of link pitch is different from the

basic value depending upon the precision of measure or the

tolerance of product even if it isn't worn out.

Don't judge it's worn out too soon, do it with the trend of measured

value after that.

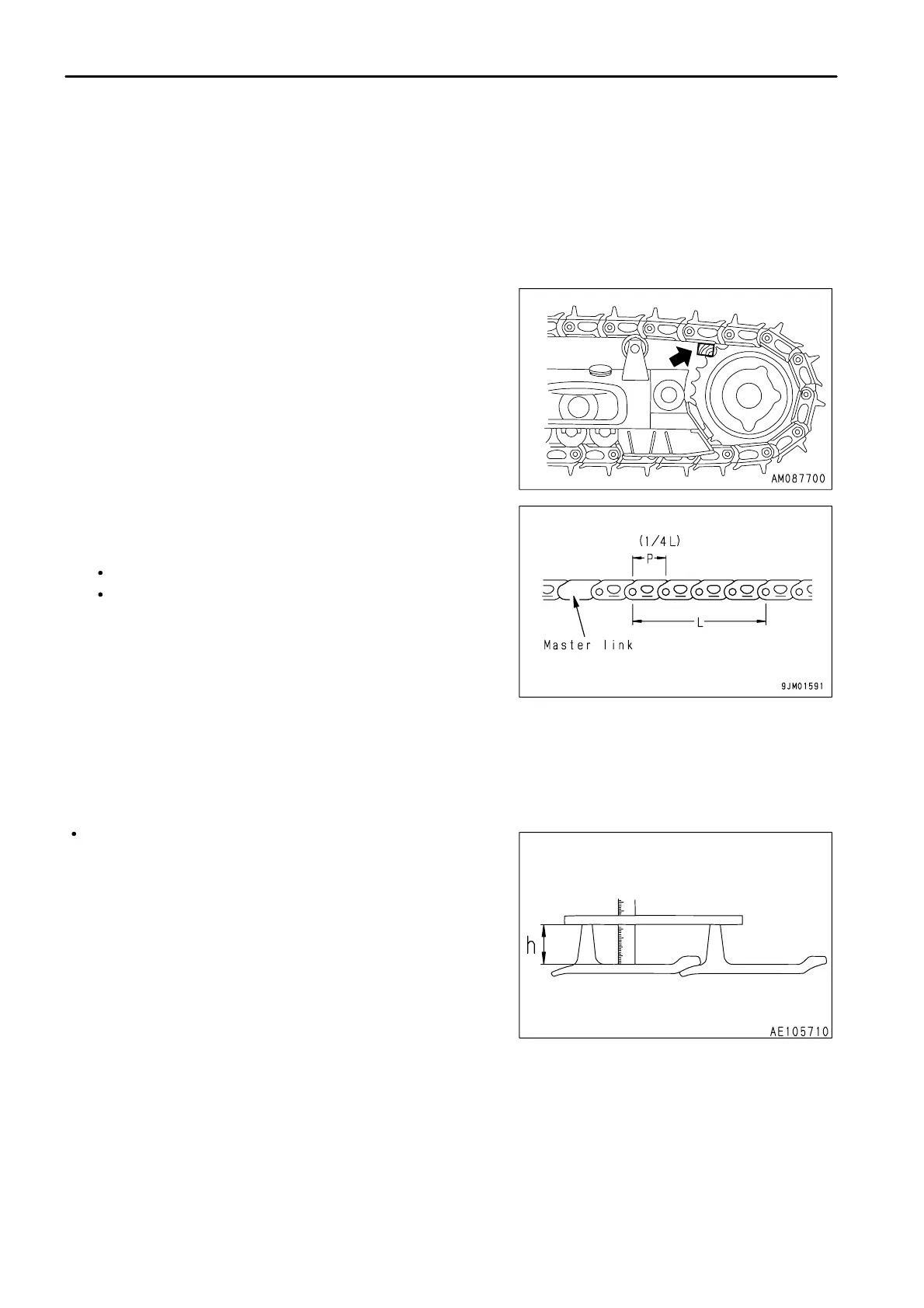

MEASURING HEIGHT OF GROUSER

After taking up slack in track shoes, measure height at center of

shoe as shown below.

Standard height (h): 72 mm (2.8 in)

Repair limits: 25 mm (1.0 in)

3 - 128

Loading...

Loading...