16 ENGINE 126

304539-10

– Check the sealing area of the cylinder head for distortion using a straight edge and

the special tool.

Feeler gauge (59029041100) ( p. 253)

Cylinder/cylinder head - distortion of

sealing area

≤ 0.10 mm (≤ 0.0039 in)

» If the measured value does not equal the specified value:

– Change the cylinder and piston.

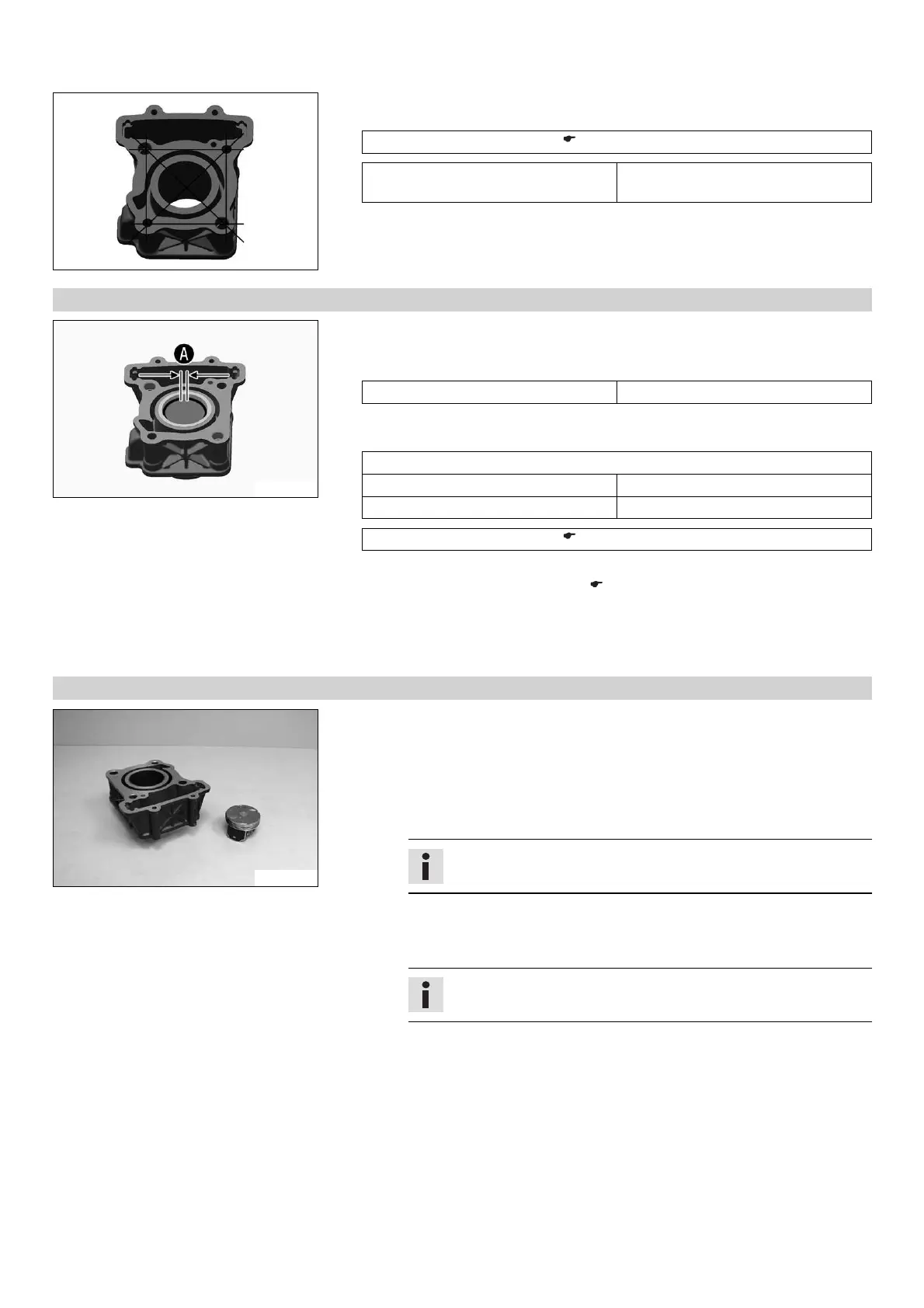

16.4.12 Checking the piston ring end gap (125 Duke)

304519-10

– Remove the piston ring from the piston.

– Place the piston ring in the cylinder and align it with the piston.

Guideline

Under the upper edge of the cylinder 20 mm (0.79 in)

– Measure end gap A with the special tool.

Guideline

Piston ring end gap

Compression ring ≤ 0.40 mm (≤ 0.0157 in)

Oil scraper ring ≤ 0.80 mm (≤ 0.0315 in)

Feeler gauge (59029041100) ( p. 253)

» If the end gap is more than the specified value:

– Check/measure the cylinder. ( p. 125)

» If the cylinder wear is within the tolerance range:

– Change the piston ring.

– Mount the piston ring with the marking facing toward the piston head.

16.4.13 Checking/measuring the piston (125 Duke)

304550-10

– Check the piston bearing surface for damage.

» If the piston bearing surface is damaged:

– Change the piston and, if necessary, the cylinder.

– Check that the piston rings can move easily in the piston ring grooves.

» If the piston ring is stiff:

– Clean the piston ring groove.

Tip

Use an old piston ring to clean the piston ring groove.

– Check the piston rings for damage.

» If the piston ring is damaged:

– Change the piston ring.

Info

Mount the piston ring with the marking facing upward.

– Check the piston pin for discoloration or signs of wear.

» If the piston pin has strong discoloration/signs of wear:

– Change the piston pin.

– Insert the piston pin into the connecting rod and check the bearing for play.

» If the piston pin bearing has too much play:

– Change the connecting rod and the piston pin.

Loading...

Loading...