16 ENGINE 133

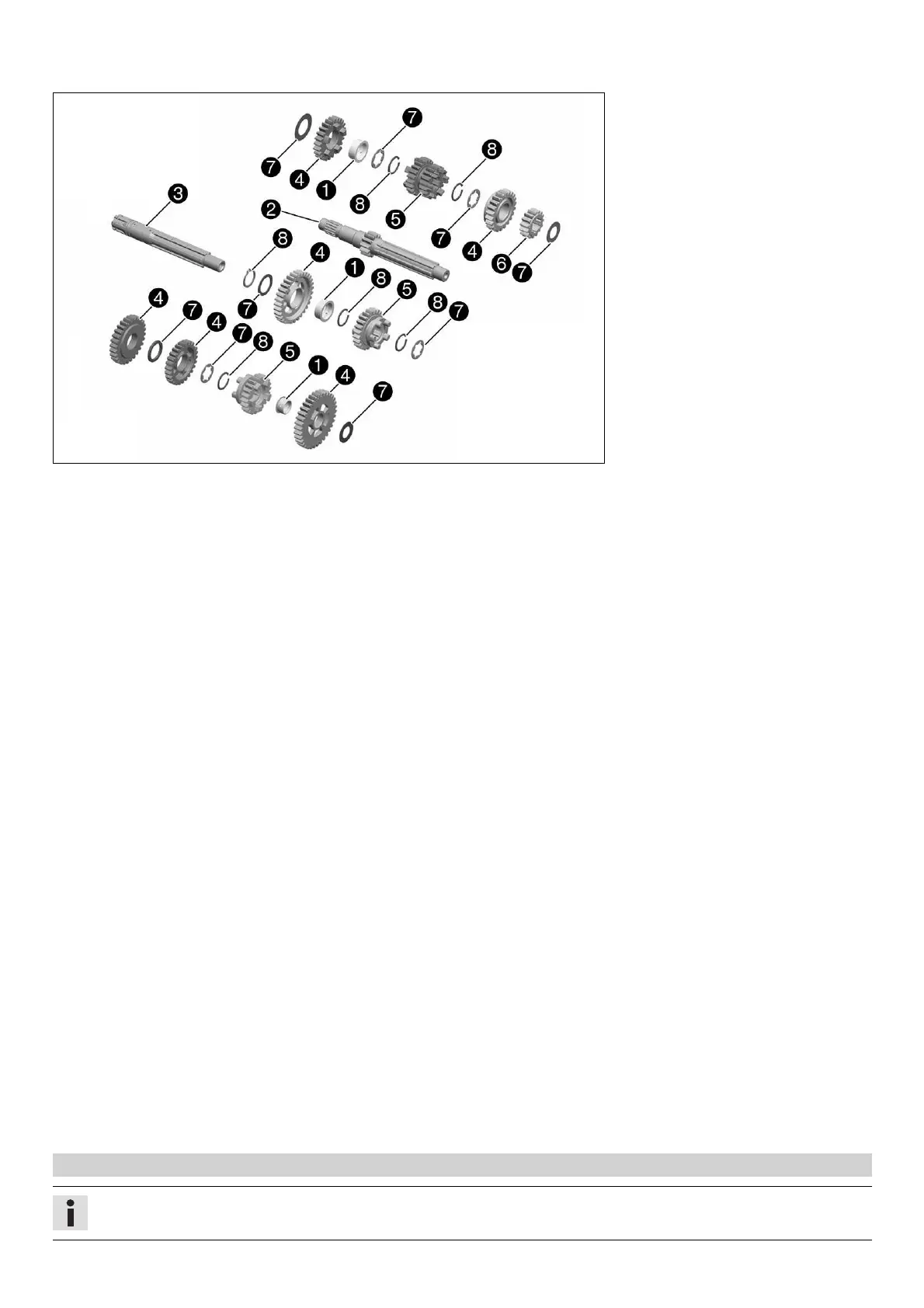

305902-10

– Check collar bushings 1 for damage and wear.

» If there is damage or wear:

– Change the collar bushings.

– Check the pivot points of main shaft 2 and countershaft 3 for damage and wear.

» If there is damage or wear:

– Change the main shaft and/or countershaft.

– Check the tooth profiles of main shaft 2 and countershaft 3 for damage and wear.

» If there is damage or wear:

– Change the main shaft and/or countershaft.

– Check the pivot points of idler gears 4 for damage and wear.

» If there is damage or wear:

– Change the gear wheel pair.

– Check the shift dogs of idler gears 4 and sliding gears 5 for damage and wear.

» If there is damage or wear:

– Change the gear wheel pair.

– Check the tooth faces of idler gears 4, sliding gears 5, and fixed gear 6 for damage and wear.

» If there is damage or wear:

– Change the gear wheel pair.

– Check the tooth profiles of sliding gears 5 for damage and wear.

» If there is damage or wear:

– Change the gear wheel pair.

– Check sliding gears 5 for smooth operation in the profile of main shaft 2.

» If the sliding gear does not move easily:

– Change the sliding gear or the main shaft.

– Check sliding gears 5 for smooth operation in the profile of countershaft 3.

» If the sliding gear does not move easily:

– Change the sliding gear or the countershaft.

– Check stop disks 7 for damage and wear.

» If there is damage or wear:

– Change the stop disk.

– Use new lock rings 8 with every repair.

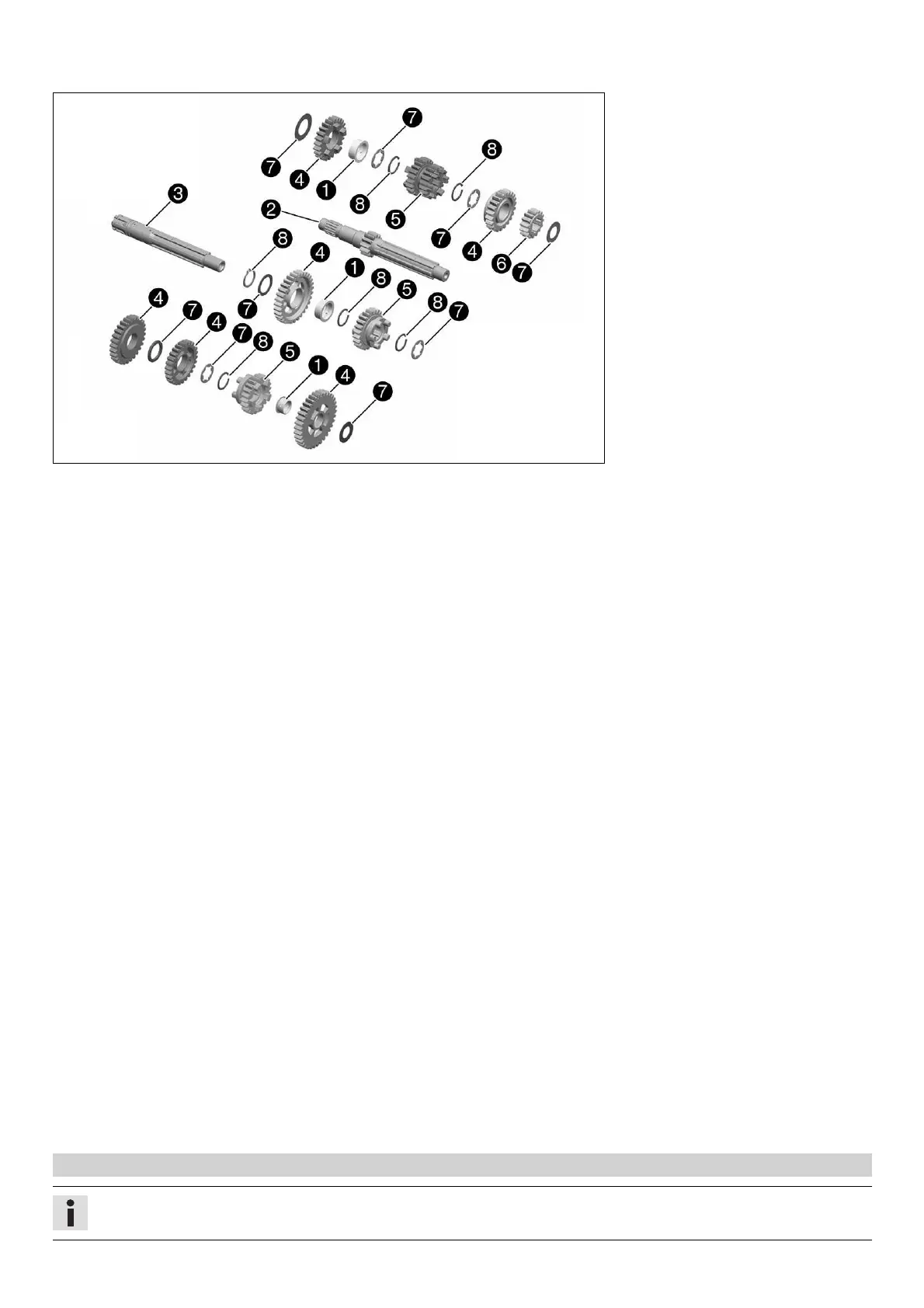

16.4.24 Assembling the main shaft (125 Duke)

Info

Use new lock rings in every repair job.

Loading...

Loading...