16 ENGINE 158

» If there is damage or wear:

– Replace the freewheel gear and/or the bearing.

– Check toothing 4 of the starter motor for damage and wear.

» If there is damage or wear:

– Replace the starter motor.

– Replace the O-ring 5 of the starter motor.

– Clamp the minus (negative) cable of a 12 Volt power supply to the starter motor housing. Briefly connect the positive cable of the

power supply to the starter motor connection.

» If the starter motor does not turn when you close the power circuit:

– Replace the starter motor.

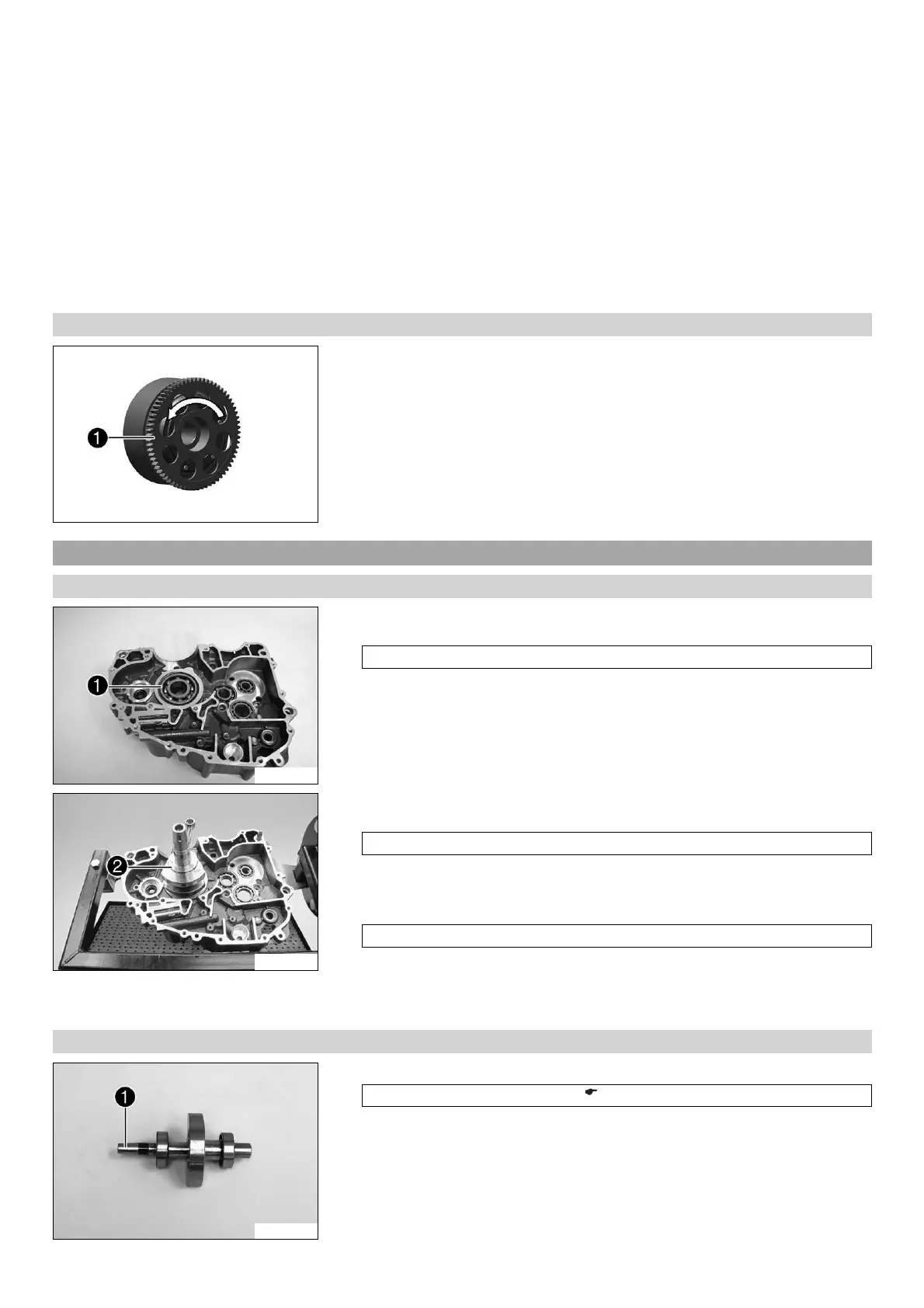

16.4.58 Checking the freewheel (200 Duke)

304255-10

– Insert freewheel gear 1 into the freewheel hub by turning the freewheel gear clock-

wise; do not wedge!

– Check the locking action of the freewheel gear.

» If the freewheel gear does not turn clockwise or if it does not lock counterclock-

wise:

– Replace the freewheel.

16.5 Assembling the engine

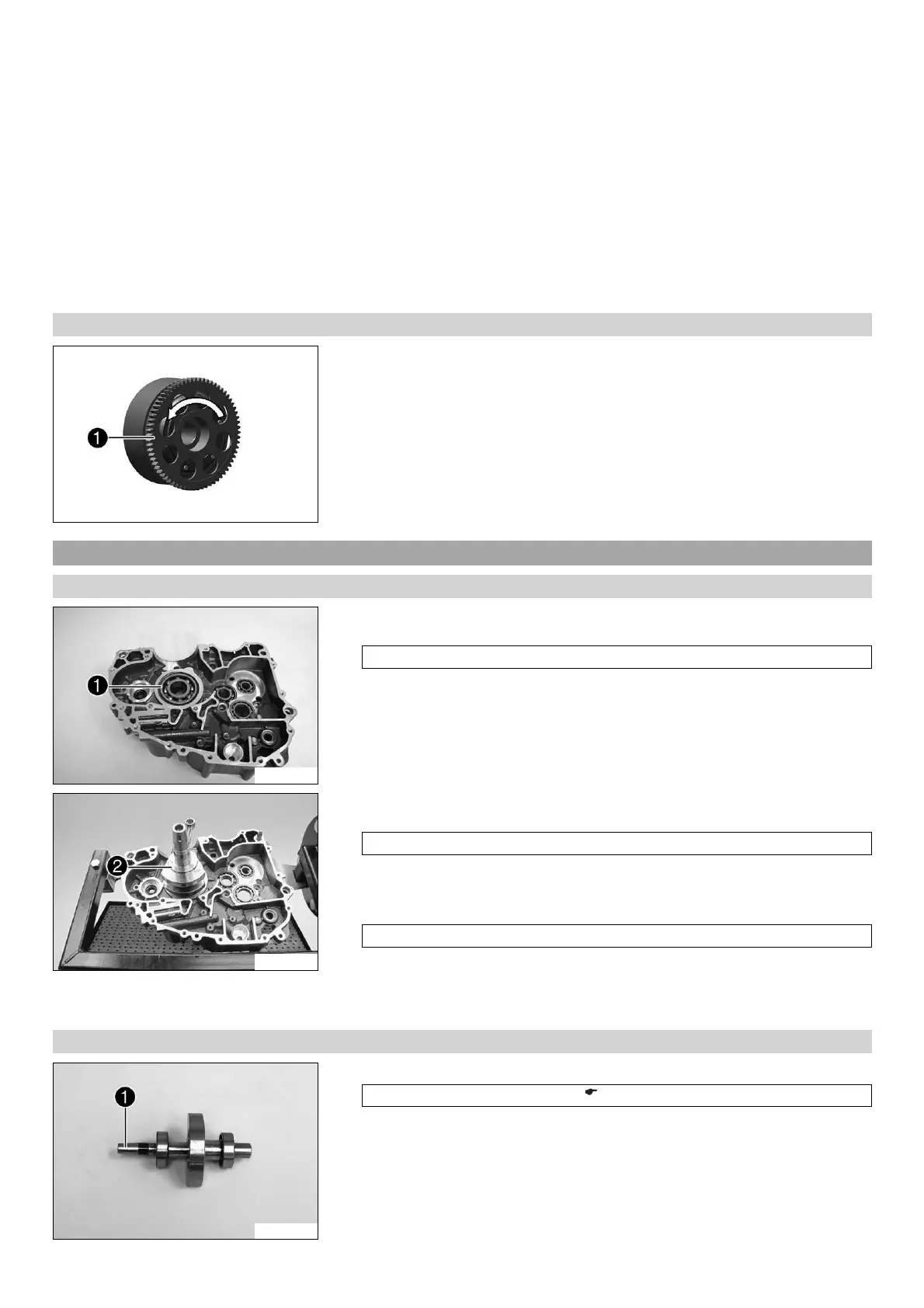

16.5.1 Installing the crankshaft (125 Duke)

304801-10

– Warm the engine case section in an oven.

Guideline

150 °C (302 °F)

– Mount main bearing 1.

304802-10

– Heat the main bearing.

Guideline

150 °C (302 °F)

– Slide crankshaft 2 into the bearing seat.

– Heat the left main bearing.

Guideline

150 °C (302 °F)

– Mount the main bearing on the crankshaft.

– Cool the main bearing.

– Oil the bearing.

16.5.2 Installing the balancer shaft (125 Duke)

304503-10

– Mount special tool 1.

Mounting sleeve (90129005000) ( p. 256)

Loading...

Loading...