4-35

4 System Design

G5-series AC Servomotors and Servo Drives User’s Manual (with Built-in EtherCAT Communications)

4-3 Wiring Conforming to EMC Directives

4

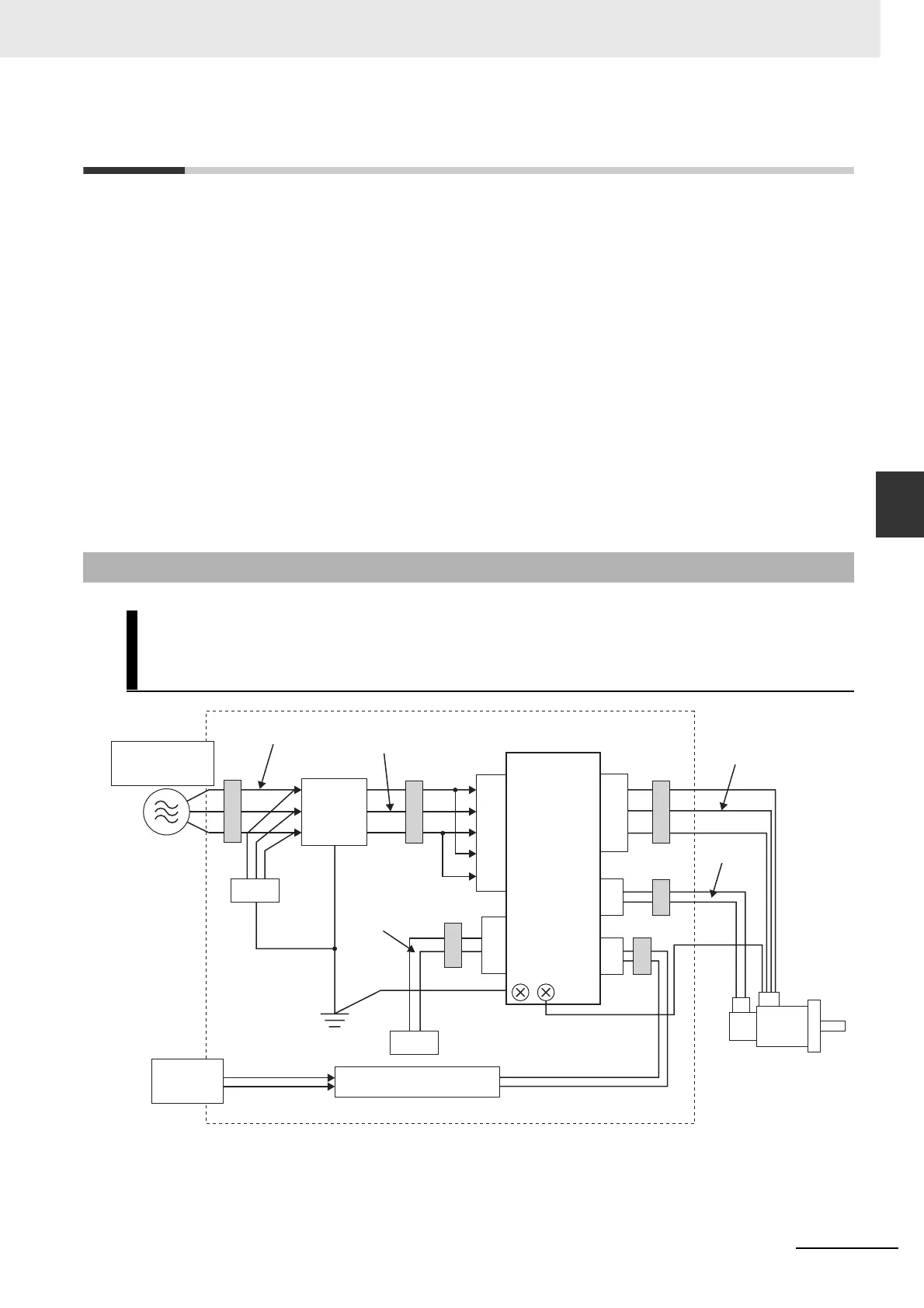

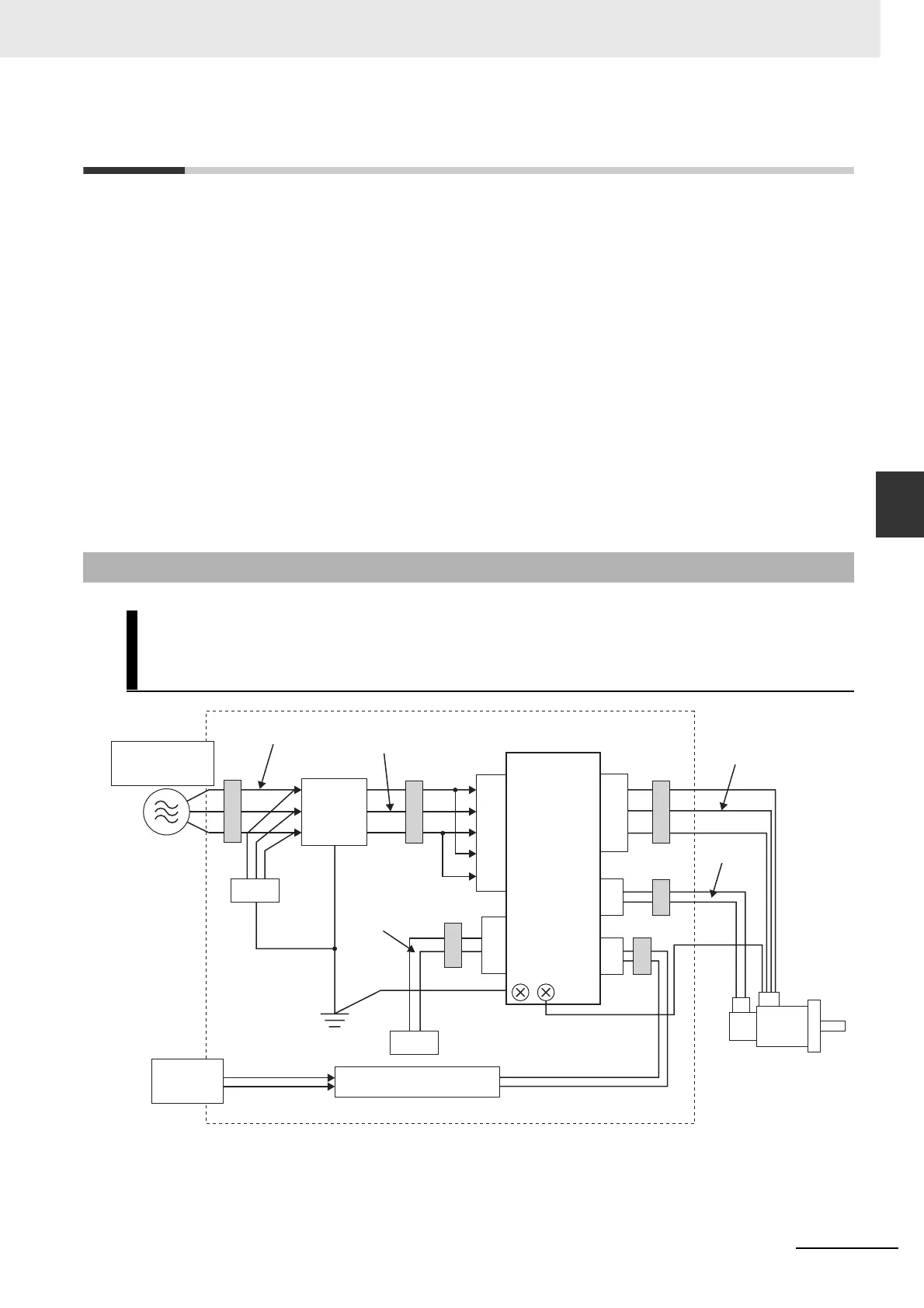

4-3-1 Wiring Method

4-3

Wiring Conforming to EMC Directives

Conformance to the EMC Directives (EN 55011 Class A Group 1 (EMI) and EN 61000-6-2 (EMS)) can

be ensured by wiring under the conditions described in this section.

These conditions are for conformance of G5-series products to the EMC directives. EMC-related

performance of these products, however, may be influenced by the configuration, wiring, and other

conditions of the equipment in which the products are installed. The EMC conformance of the system

as a whole must be confirmed by the customer.

The following are the requirements for EMC Directive conformance.

• The Servo Drive must be installed in a metal case (control panel). (The motor does not, however,

have to be covered with a metal plate.)

• Noise filters and lightening surge absorptive elements (surge absorbers) must be installed on power

supply lines.

• Braided shielded cables must be used for all I/O signal cables and encoder cables. (Use tin-plated,

mild steel wires for the shielding.)

• All cables, I/O wiring, and power lines connected to the Servo Drive must have clamp cores installed.

• The shields of all cables must be directly connected to a ground plate.

*1 Not required for single-phase models with a 100-VAC input.

Note For models with a single-phase power supply input (R88D-KNA5L-ECT/-KN01L-ECT/-KN02L-ECT/-KN04L-

ECT/-KN01H-ECT/-KN02H-ECT/-KN04H-ECT/-KN08H-ECT), the main circuit power supply input terminals

are L1 and L3.

4-3-1 Wiring Method

R88D-KNA5L-ECT/-KN01L-ECT/-KN02L-ECT/-KN04L-ECT/-KN01H-ECT/

-KN02H-ECT/-KN04H-ECT/-KN08H-ECT/-KN10H-ECT/-KN15H-ECT/

-KN20H-ECT/-KN30H-ECT/-KN50H-ECT/-KN75H-ECT/-KN150H-ECT

L1

L2

L3

L1C

L2C

1ø:100VAC

3ø:200VAC

1ø:

100VAC

SG

*1

NF

FC1 FC4

SD

FC3

FC1

CNA

CN1

CNB

CN2

U

V

W

SM

(3)

(4)

(1)

(2)

(6)

(5)

(7)

(8)

FC2

ECAT

IN

FC1

TB

Controller

Loading...

Loading...