Engine Mechanical: 1D-29

Cylinder Head and Related Parts Inspection

B705H11406014

Cylinder Head Distortion

1) Decarbonize the combustion chambers.

2) Check the gasket surface of the cylinder head for

distortion. Use a straightedge and thickness gauge.

Take clearance readings at several places. If

readings exceed the service limit, replace the

cylinder head.

Special tool

: 09900–20803 (Thickness gauge)

Cylinder head distortion

Service limit: 0.05 mm (0.002 in)

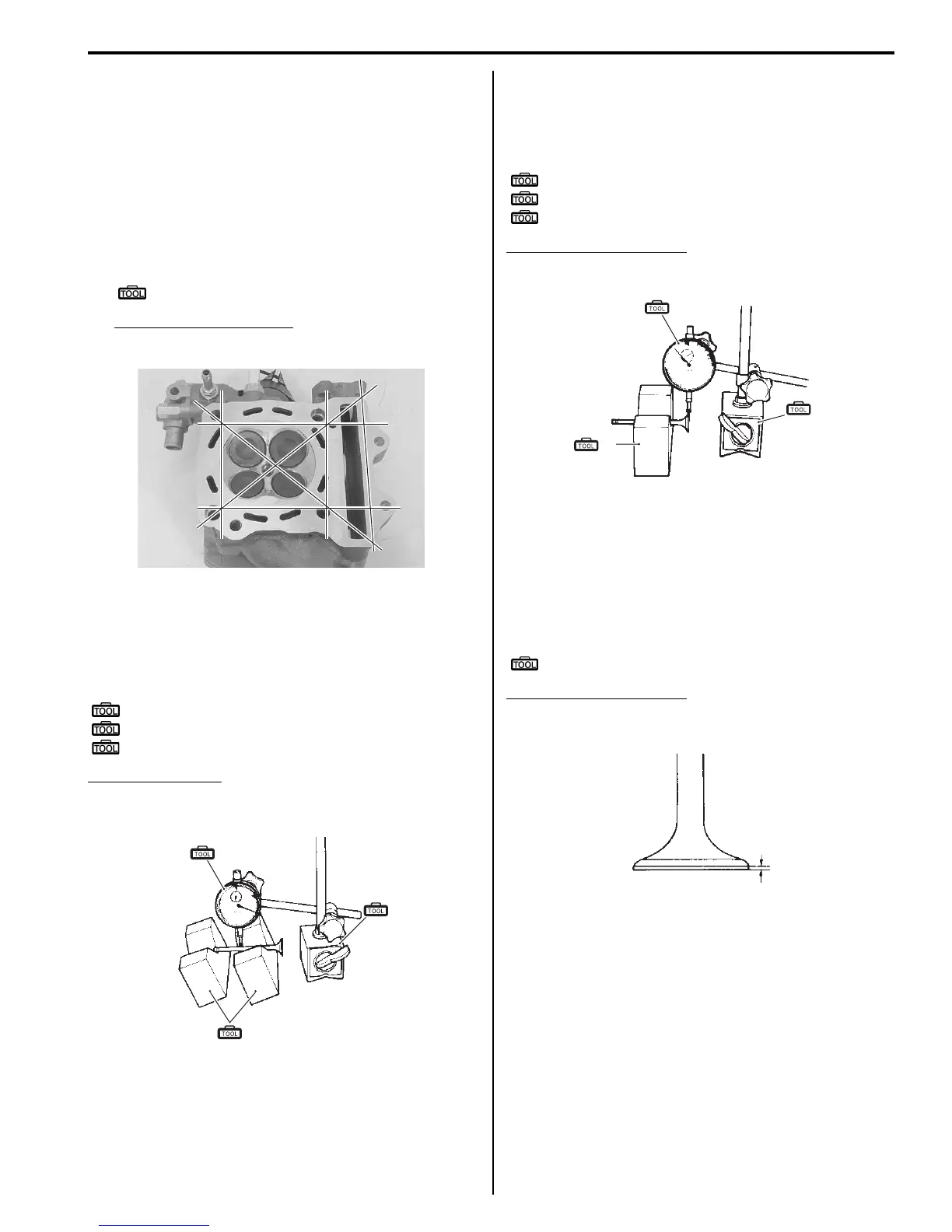

Valve Stem Runout

Support the valve using V-blocks, as shown, and check

its runout using the dial gauge. If the runout exceeds the

service limit, replace the valve.

Special tool

(A): 09900–20606 (Dial gauge (1/100 mm))

(B): 09900–20701 (Magnetic stand)

(C): 09900–21304 (V-block (100 mm))

Valve stem runout

Service limit: 0.05 mm (0.002 in)

Valve Head Radial Runout

Place the dial gauge at a right angle to the valve head

face and measure the valve head radial runout. If it

measures more than the service limit, replace the valve.

Special tool

(A): 09900–20606 (Dial gauge (1/100 mm))

(B): 09900–20701 (Magnetic stand)

(C): 09900–21304 (V-block (100 mm))

Valve head radial runout

Service limit: 0.03 mm (0.001 in)

Valve Face Wear

Visually inspect each valve face for wear. Replace any

valve with an abnormally worn face. The thickness of the

valve face decreases as the face wears. Measure the

valve face “a”. If it is out of specification replace the

valve with a new one.

Special tool

: 09900–20102 (Vernier calipers)

Valve face thickness “a”

Service limit: 0.5 mm (0.02 in)

I705H1140056-02

(A)

(C)

(B)

I649G1140231-02

(A)

(B)

(C)

I649G1140232-02

“a”

I649G1140233-01

Loading...

Loading...