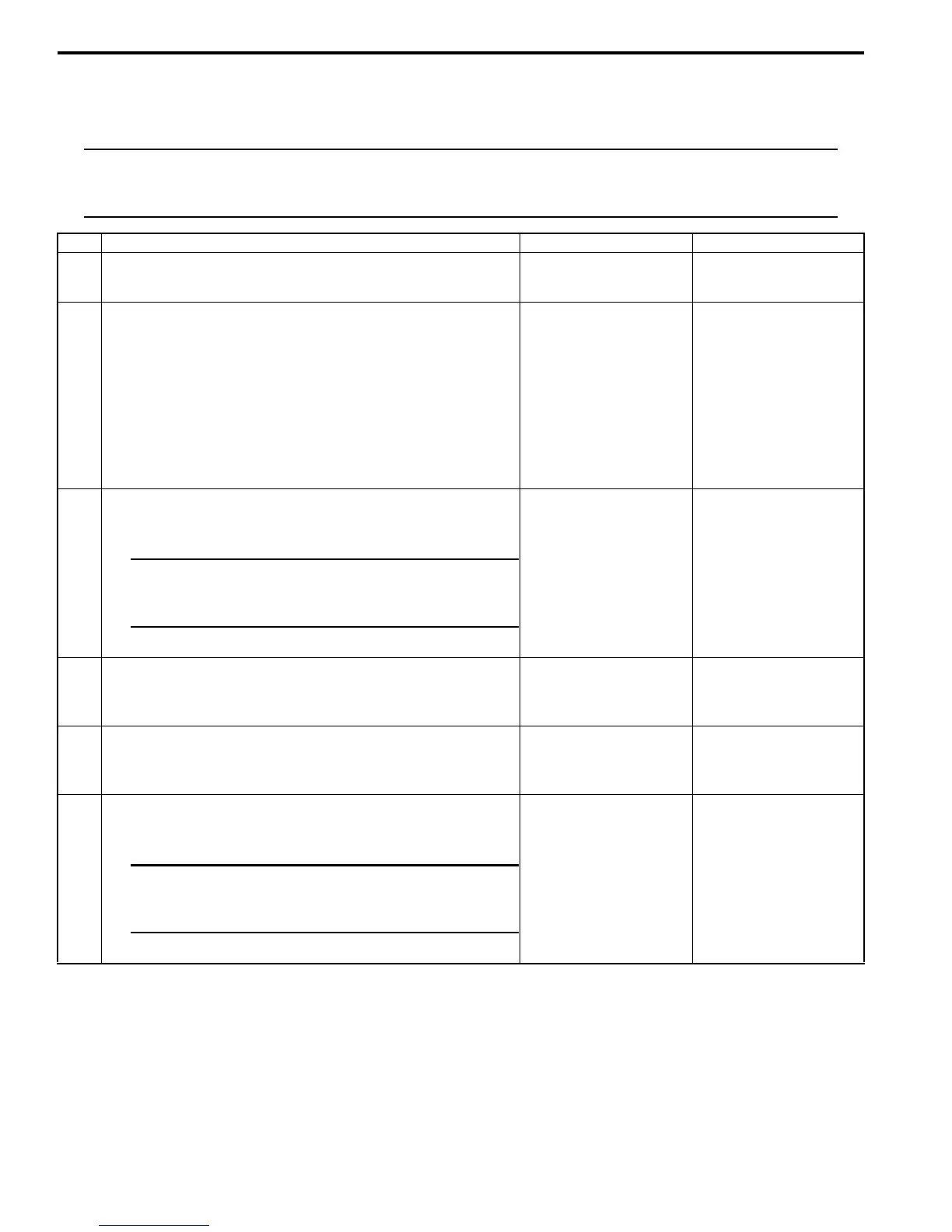

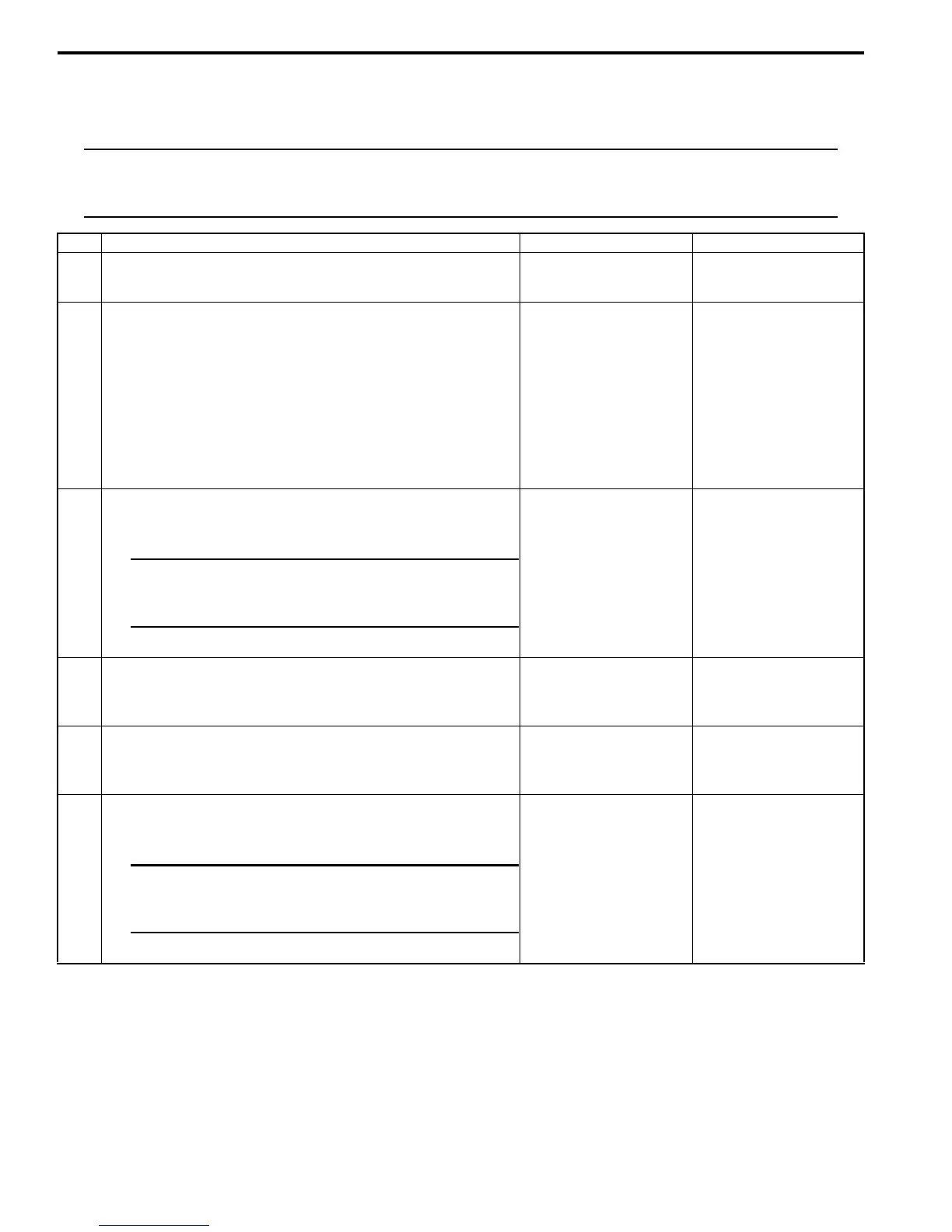

1H-4 Ignition System:

No Spark or Poor Spark

B705H11804001

Troubleshooting

NOTE

Make sure the engine stop switch is in the “RUN” position and side-stand is in up-right position.

Grasp the front or rear brake lever. Make sue the fuse is not blown and the battery is fully-charged

before diagnosing.

Step Action Yes No

1 Check the ignition system couplers for poor connections.

Is there connection in the ignition system couplers?

Go to step 2. Poor connection of

couplers.

2 Measure the battery voltage between input lead wires (O/W

and W) at the ECM with the ignition switch in the “ON”

position.

Is the voltage OK?

Go to Step 3. • Faulty ignition switch.

• Faulty turn signal/

side-stand relay.

• Faulty engine stop

switch.

• Broken wire harness

or poor connection of

related circuit

couplers.

3 Measure the ignition coil primary peak voltage. Refer to

“Ignition Coil Inspection (Page1H-5)”.

NOTE

This ignition coil primary peak voltage

inspection method is applicable only with the

multi-circuit tester and the peak volt adaptor.

Is the peak voltage OK?

Go to step 4. Go to step 5.

4 Inspect the spark plug. Refer to “Spark Plug Inspection and

Cleaning in Section 0B (Page0B-4)”.

Is the spark plug OK?

Go to Step 5. Faulty spark plug.

5 Inspect the ignition coil. Refer to “Ignition Coil Inspection

(Page1H-5)”.

Is the ignition coil(-s) OK?

Go to step 6. Faulty ignition coil(-s).

6 Measure the CKP sensor peak voltage and its resistance.

Refer to “CKP Sensor Inspection (Page1H-6)”.

NOTE

The CKP sensor peak voltage inspection is

applicable only with the multi-circuit tester and

peak volt adaptor.

Is the peak voltage and resistance OK?

•Faulty ECM.

• Poor connection of

ignition couplers.

• Faulty CKP sensor.

• Metal particles or

foreign material being

stuck on the CKP

sensor and rotor tip.

Loading...

Loading...