Engine Mechanical: 1D-51

Cam Chain Tensioner Inspection

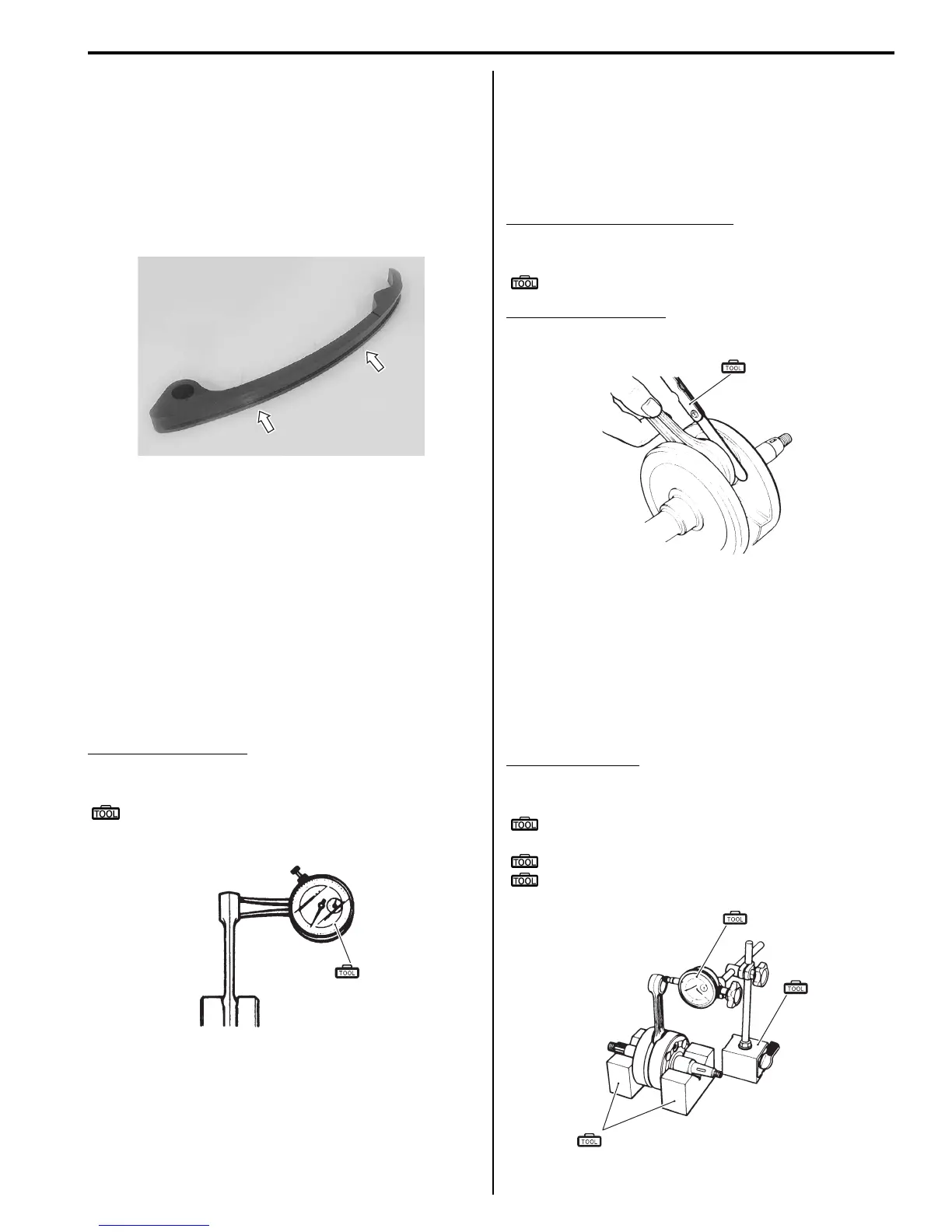

B705H11406060

Inspect the cam chain tensioner in the following

procedures:

1) Remove the cam chain tensioner. Refer to “Engine

Bottom Side Disassembly (Page1D-37)”.

2) Inspect the contacting surface of the cam chain

tensioner. If it is worn or damaged, replace the cam

chain tensioner with a new one.

3) Install the cam chain tensioner. Refer to “Engine

Bottom Side Assembly (Page1D-44)”.

Conrod and Crankshaft Inspection

B705H11406025

Refer to “Engine Bottom Side Disassembly (Page1D-

37)”.

Refer to “Engine Bottom Side Assembly (Page1D-44)”.

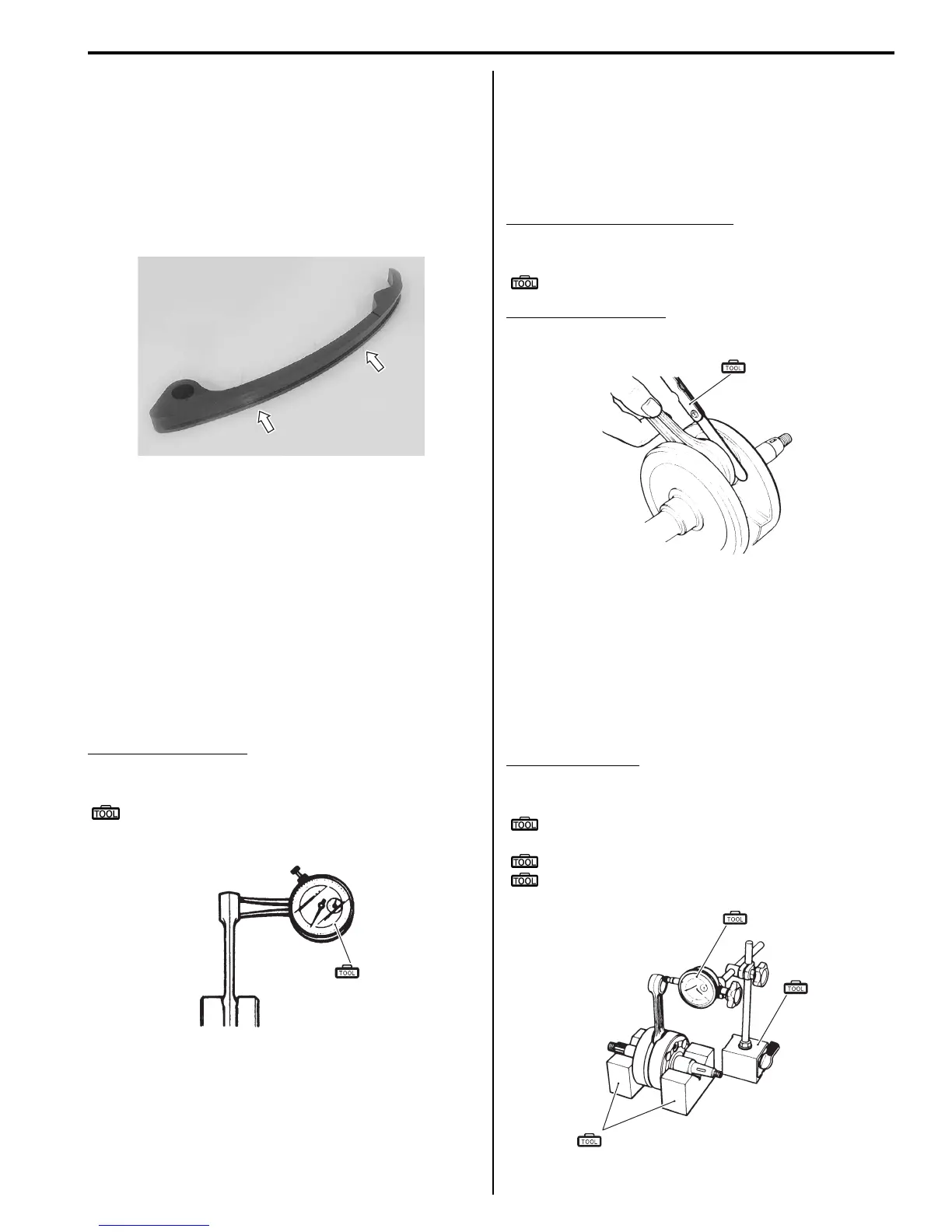

Conrod Small End I.D.

Measure the conrod small end inside diameter using the

small bore gauge.

If the conrod small end inside diameter exceeds the

service limit, replace the conrod.

Conrod small end I.D.

Service limit: 20.040 mm (0.789 in)

Special tool

(A): 09900–20605 (Dial calipers (1/100 mm, 10 –

34 mm))

Conrod Big End Side Clearance

Inspect the conrod side clearance using the thickness

gauge.

If the clearance exceeds the limit, inspect the conrod big

end width and crank pin width.

If the width exceed the limit, replace conrod or

crankshaft.

Conrod big end side clearance

Limit: 1.00 mm (0.04 in)

Special tool

(A): 09900–20803 (Thickness gauge)

Conrod big end width

Standard: 21.95 – 22.00 mm (0.864 – 0.866 in)

Conrod Deflection

Move the small end sideways while holding the big end

immovable in thrust direction.

Measure the amount of deflection.

Turn the conrod and see if it moves smoothly without

play and noise.

This method can check the extent of wear on the parts of

the conrod’s big end.

Conrod deflection

Service limit: 3.0 mm (0.12 in)

Special tool

(A): 09900–20607 (Dial gauge (1/100 mm, 10

mm))

(B): 09900–20701 (Magnetic stand)

(C): 09900–21304 (V-block (100 mm))

I705H1140144-01

(A)

I705H1140145-02

(A)

I705H1140146-02

(A)

(B)

(C)

I705H1140147-02

Loading...

Loading...