Wheels and Tires: 2D-11

Rear Wheel Related Parts Inspection

B705H12406026

Refer to “Rear Wheel Assembly Removal and

Installation (Page2D-9)”.

Refer to “Rear Wheel Components (Page2D-8)”.

Inspect the rear wheel related parts.

Tire

Refer to “Tire Inspection in Section 0B (Page0B-15)”.

Rear Brake Disc

Refer to “Rear Brake Disc Removal and Installation in

Section 4C (Page4C-9)”.

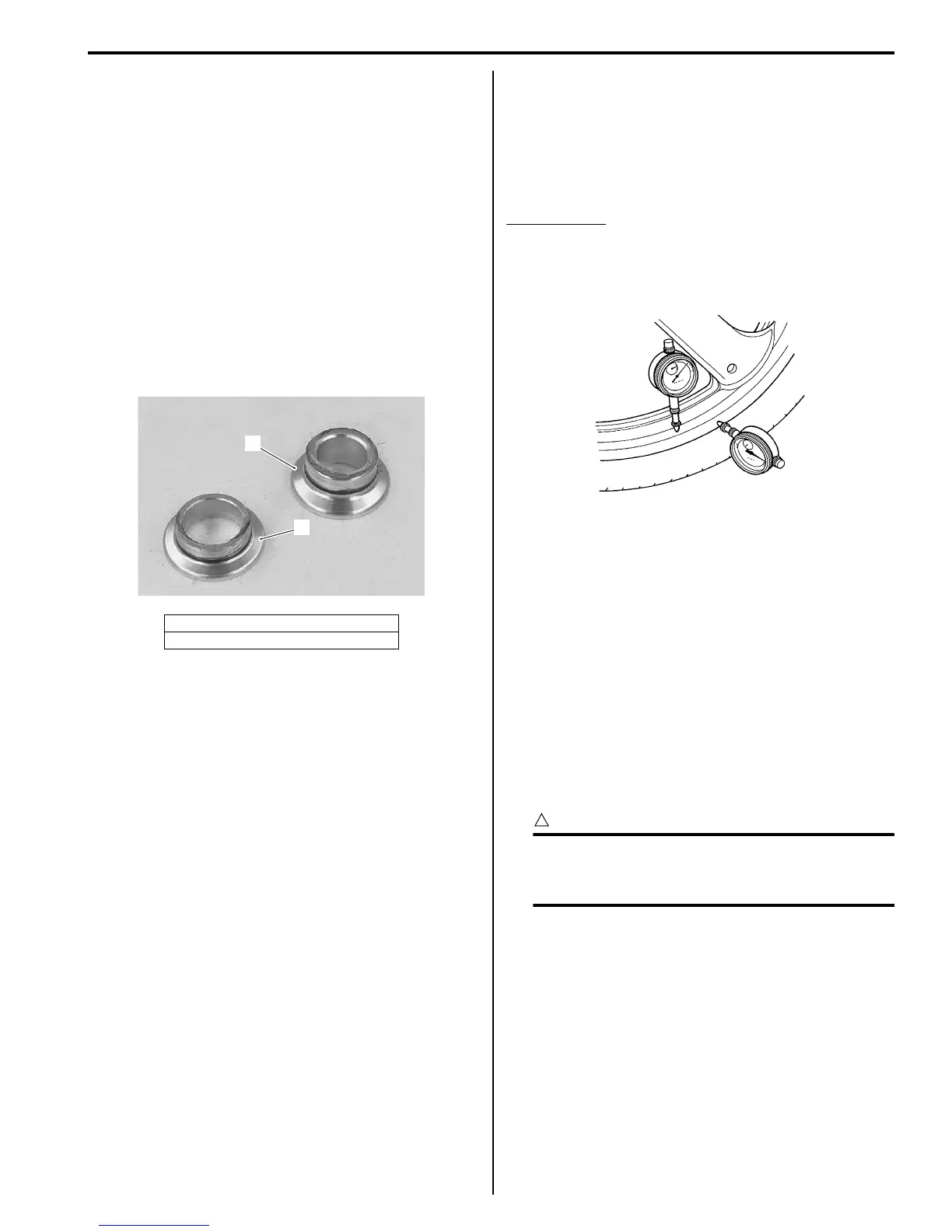

Collar

Inspect the collars for wear or damage. If any defects are

found, replace it with a new one.

Rear Swingarm

Refer to “Rear Suspension Components in Section 2C

(Page2C-1)”.

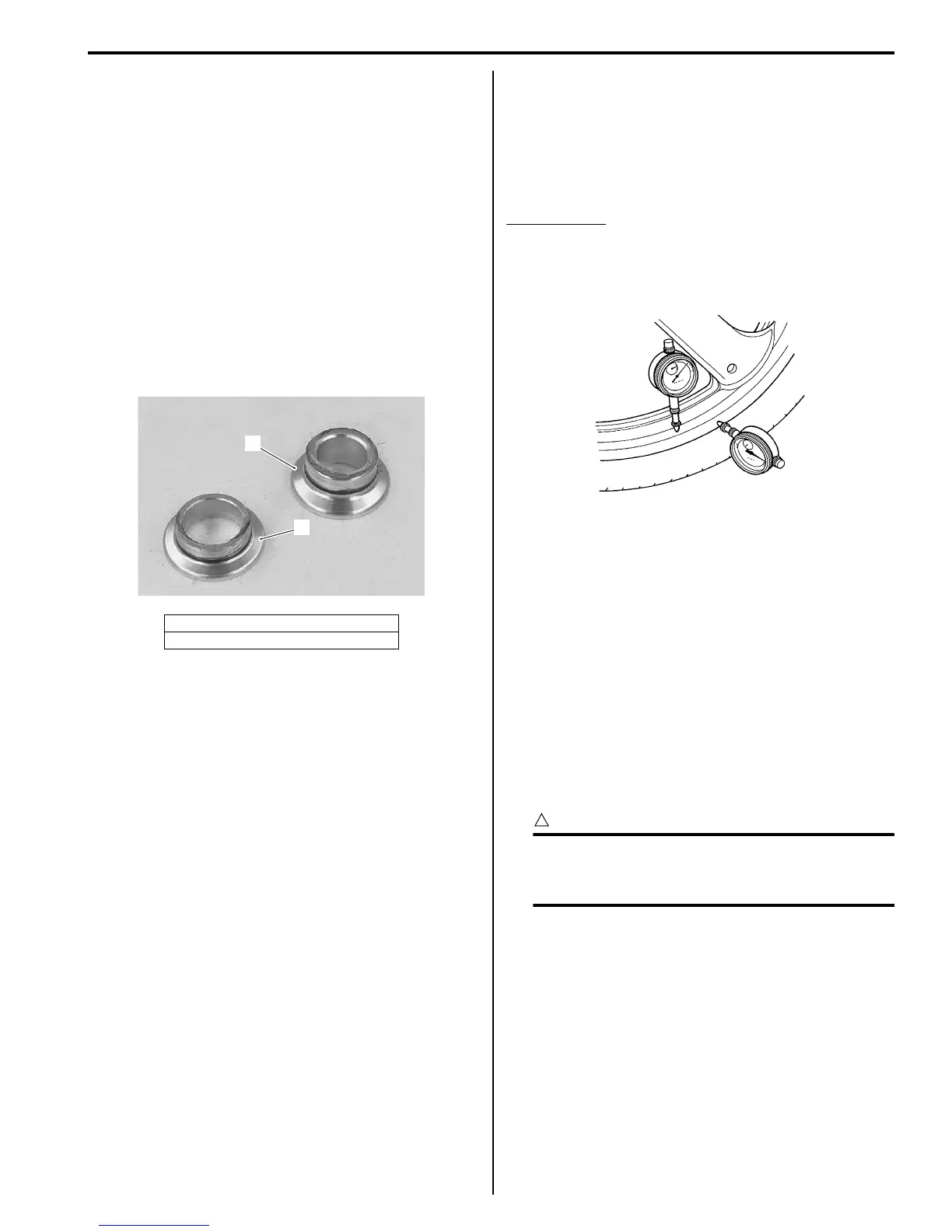

Wheel

Make sure that the wheel runout checked as shown

does not exceed the service limit. An excessive runout is

usually due to worn or loosened wheel bearings and can

be reduced by replacing the bearings. If bearing

replacement fails to reduce the runout, replace the

wheel.

Wheel runout

Service limit (Axial and Radial): 2.0 mm (0.08 in)

Wheel clean and check. Refer to “Wheel/Tire/Air Valve

Inspection and Cleaning (Page2D-13)”.

Tire Removal and Installation

B705H12406027

Removal

The most critical factor of a tubeless tire is the seal

between the wheel rim and the tire bead. For this

reason, it is recommended to use a tire changer that can

satisfy this sealing requirement and can make the

operation efficient as well as functional.

1) Removal the wheel assembly. Refer to “Front Wheel

Assembly Removal and Installation (Page2D-4)” and

“Rear Wheel Assembly Removal and Installation

(Page2D-9)”.

2) Remove the valve core.

3) Remove the tire using the tire changer.

CAUTION

!

For operating procedures, refer to the

instructions supplied by the tire changer

manufacturer.

1. Collar for lock-nut (Outer side)

2. Collar for wheel (Inner side)

1

2

I705H1240026-01

I649G1240014-01

Loading...

Loading...