Wheels and Tires: 2D-13

7) When the bead has been fitted properly, adjust the

pressure to specification.

8) As necessary, adjust the tire balance. Refer to

“Wheel Balance Check and Adjustment (Page2D-

14)”.

Cold inflation tire pressure

9) Install the wheel assembly. Refer to “Front Wheel

Assembly Removal and Installation (Page2D-4)” and

“Rear Wheel Assembly Removal and Installation

(Page2D-9)”.

Wheel/Tire/Air Valve Inspection and Cleaning

B705H12406028

Refer to “Tire Removal and Installation (Page2D-11)”.

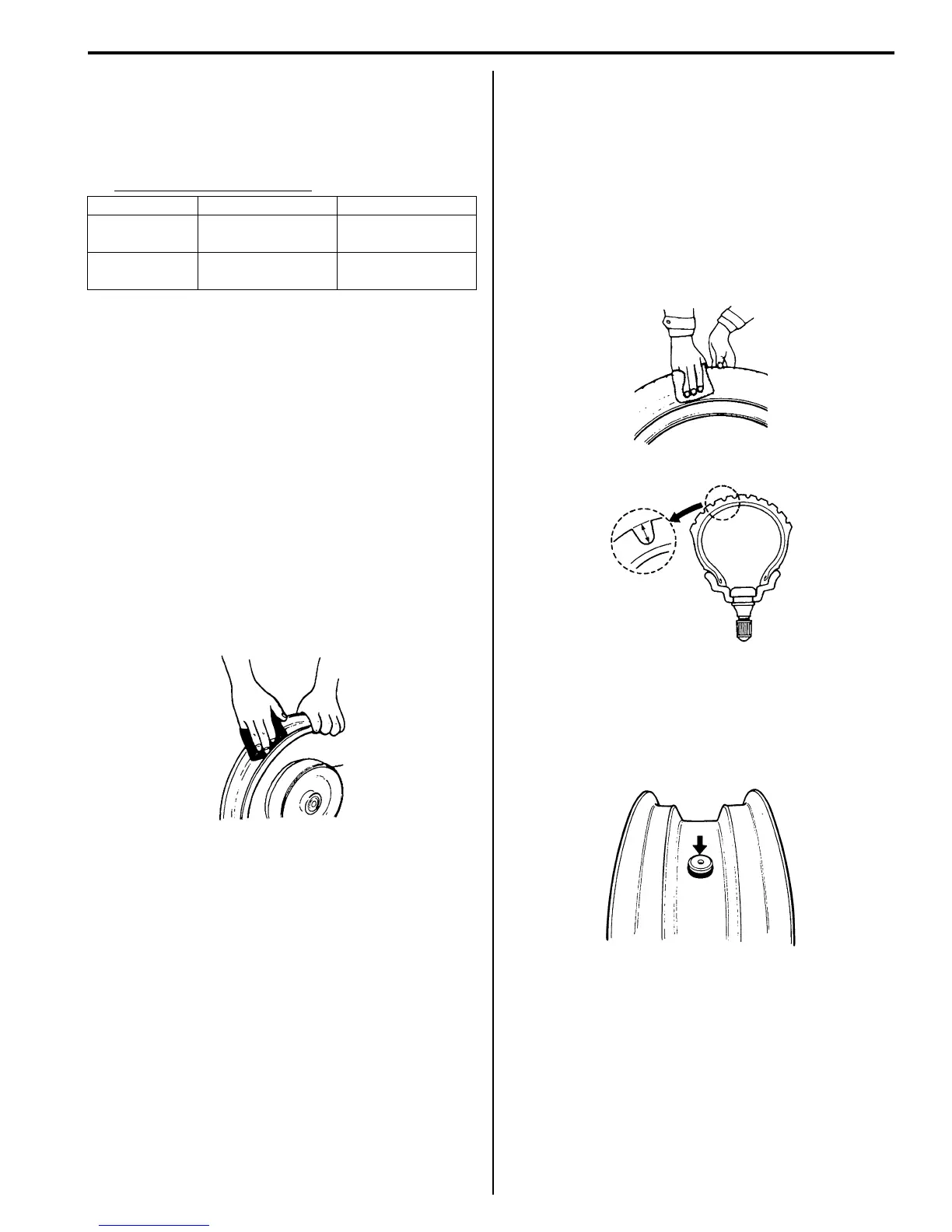

Wheel

Wipe the wheel clean and check for the following points:

• Distortion and crack

• Any flaws and scratches at the bead seating area.

• Wheel rim runout. Refer to “Front Wheel Assembly

Removal and Installation (Page2D-4)” and “Rear

Wheel Assembly Removal and Installation (Page2D-

9)”.

Tire

Tire must be checked for the following points:

• Nick and rupture on side wall

• Tire tread depth (Refer to “Tire Inspection in Section

0B (Page0B-15)”.)

• Tread separation

• Abnormal, uneven wear on tread

• Surface damage on bead

• Localized tread wear due to skidding (Flat spot)

• Abnormal condition of inner liner

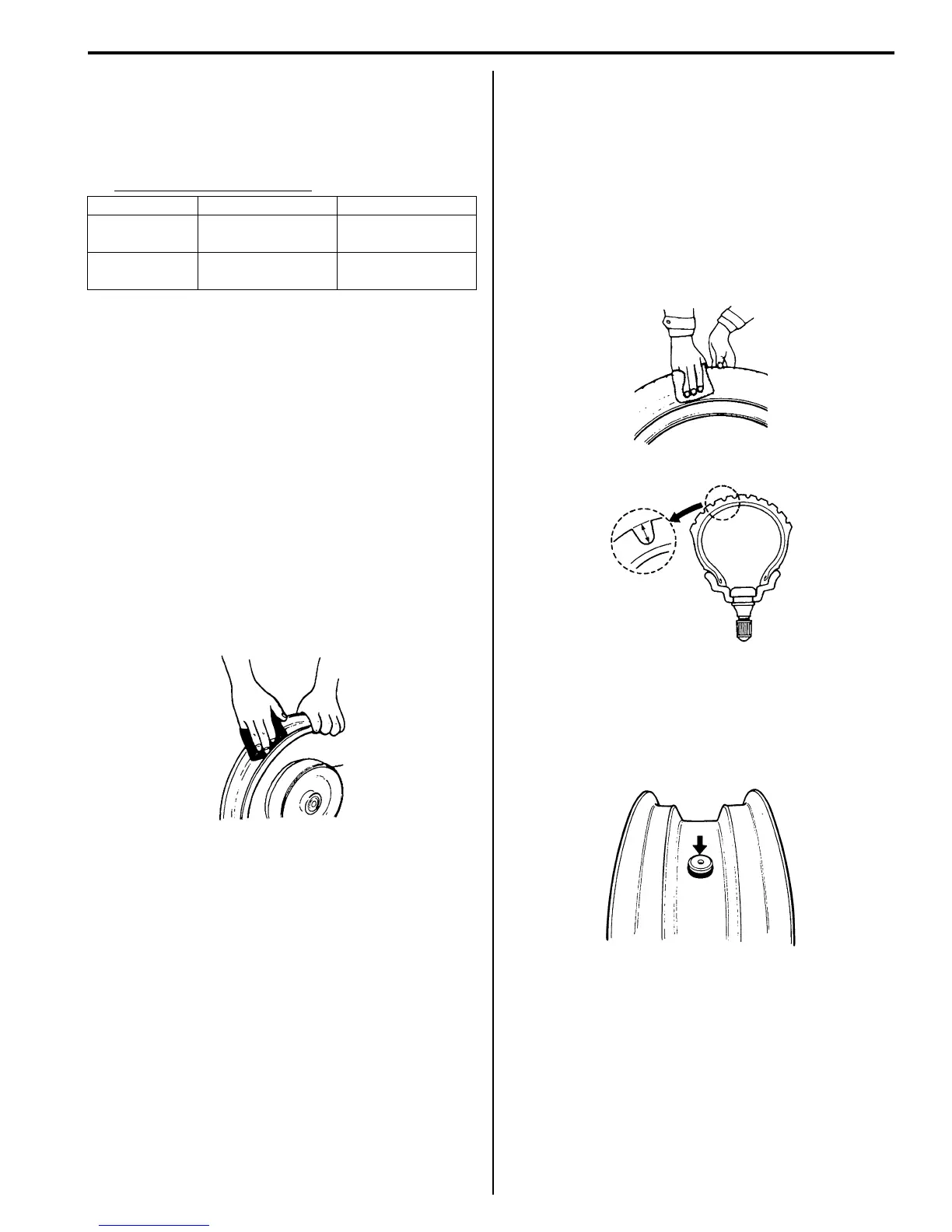

Air Valve

Inspect the air valve for peeling and damage. If any

defect is found, replace the air valve with a new one.

Refer to “Air Valve Removal and Installation (Page2D-

14)”.

Front Rear

Solo riding

175 kPa

(1.75 kgf/cm

2

)

200 kPa

(2.00 kgf/cm

2

)

Dual riding

175 kPa

(1.75 kgf/cm

2

)

250 kPa

(2.50 kgf/cm

2

)

I649G1240041-01

I649G1240042-01

I649G1240043-01

I649G1240044-01

Loading...

Loading...