Fundamentals, File Management | Fundamentals

4

HEIDENHAIN | TNC 620 | Conversational Programming User's Manual | 10/2017

141

Reference systems

For the control to traverse an axis according to a defined path it

requires a reference system.

A paraxially mounted linear encoder on a machine tool serves

as a simple reference system for linear axes. The linear encoder

represents a number ray, a unidimensional coordinate system.

To approach a point on the plane, the control requires two axes and

therefore a reference system with two dimensions.

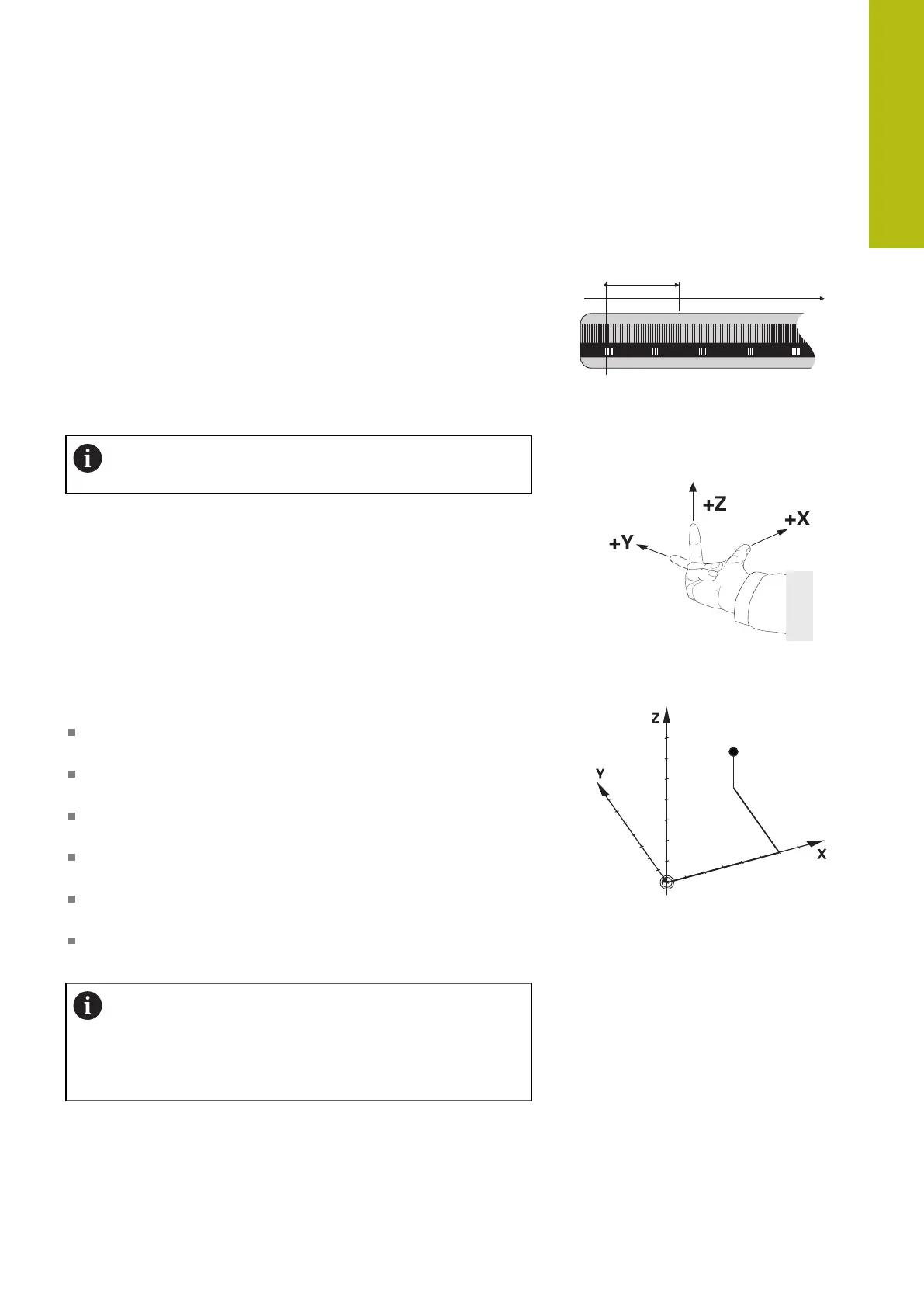

To approach a point in the space, the control requires three axes

and therefore a reference system with three dimensions. If these

three axes are configured perpendicular to each other this creates a

so-called three-dimensional Cartesian coordinate system.

According to the right-hand rule the fingertips point in

the positive directions of the three main axes.

For a point to be uniquely determined in space, a coordinate origin

is needed in addition to the configuration of the three dimensions.

The common intersection serves as the coordinate origin in a 3-D

coordinate system. This intersection has the coordinates X+0, Y+0

and Z+0.

The control must differentiate between various reference systems

for it to always perform a tool change at the same position for

example, or carry out a machining operation always related to the

current workpiece position.

The control differentiates between the following reference

systems:

Machine coordinate system M-CS:

Machine Coordinate System

Basic coordinate system B-CS:

Basic Coordinate System

Workpiece coordinate system W-CS:

Workpiece Coordinate System

Working plane coordinate system WPL-CS:

Working Plane Coordinate System

Input coordinate system I-CS:

Input Coordinate System

Tool coordinate system T-CS:

Tool Coordinate System

All reference systems build up on each other. They are

subject to the kinematic chain of the specific machine

tool.

The machine coordinate system is the reference

system.

Loading...

Loading...