Data Transfer from CAD Files | CAD import (option 42)

8

338

HEIDENHAIN | TNC 620 | Conversational Programming User's Manual | 10/2017

Selecting and saving machining positions

Operating notes:

Demo mode is active if option 42 is not enabled.

You can select a maximum of 10 elements in demo

mode.

If the contour elements are very close to one

another, use the zoom function.

If required, configure the basic settings so that the

control shows the tool paths. Further information:

"Basic settings", page 327

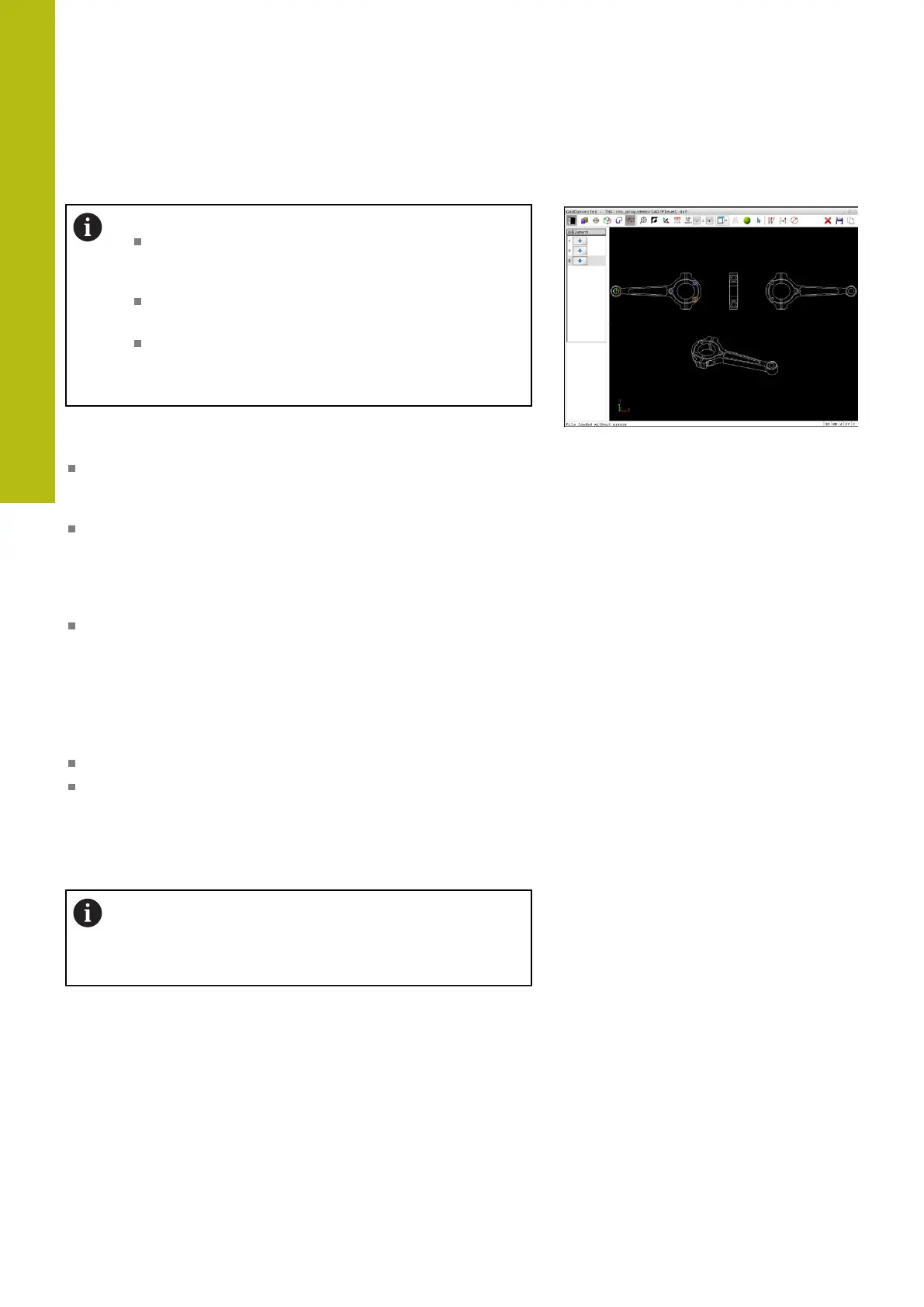

Three possibilities are available in the pattern generator for defining

machining positions:

Single selection: You select the desired machining position

through individual mouse clicks.

Further information: "Single selection", page 339

Rapid selection of hole positions with the mouse area: By

dragging the mouse to define an area, you can select all the

hole positions within this area.

Further information: "Rapid selection of hole positions with the

mouse area", page 340

Rapid selection of hole positions via an icon: Click the icon and

the control then displays all existing hole diameters.

Further information: "Rapid selection of hole positions via

icon", page 341

Selecting the file type

The following file types are available:

Point table (.PNT)

Klartext conversational language program (.H)

If you save the machining positions to a Klartext program, the

control creates a separate linear block with cycle call for every

machining position (L X... Y... Z... F MAX M99). You can also

transfer this program to older TNC controls and run it there.

The point tables (.PNT) of the TNC 640 and iTNC 530

are not compatible. Transferring and processing on the

other control type in each case may lead to problems

and unforeseen performance.

Loading...

Loading...