Multiple-Axis Machining | Three-dimensional tool compensation (option 9)

13

HEIDENHAIN | TNC 620 | Conversational Programming User's Manual | 10/2017

583

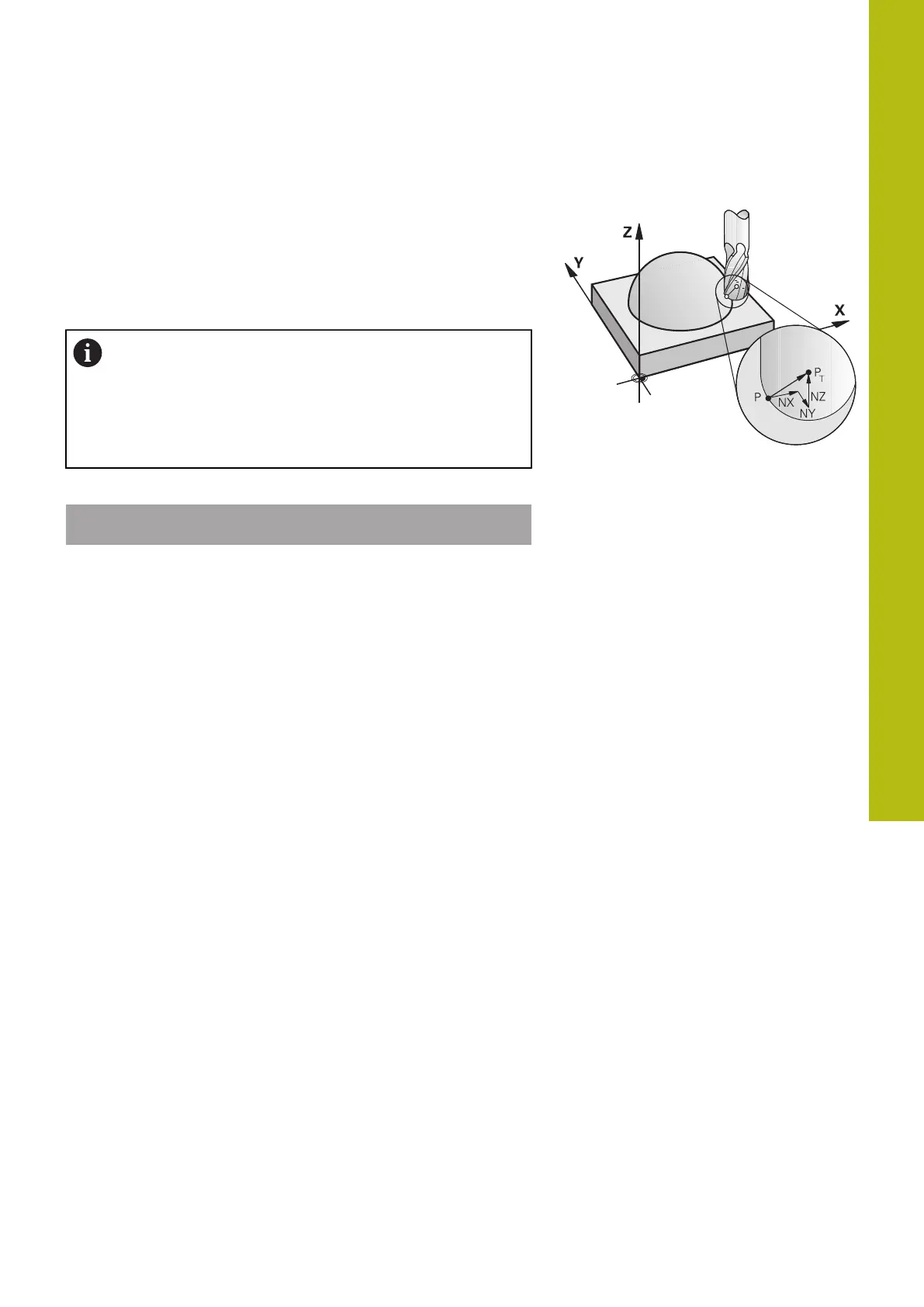

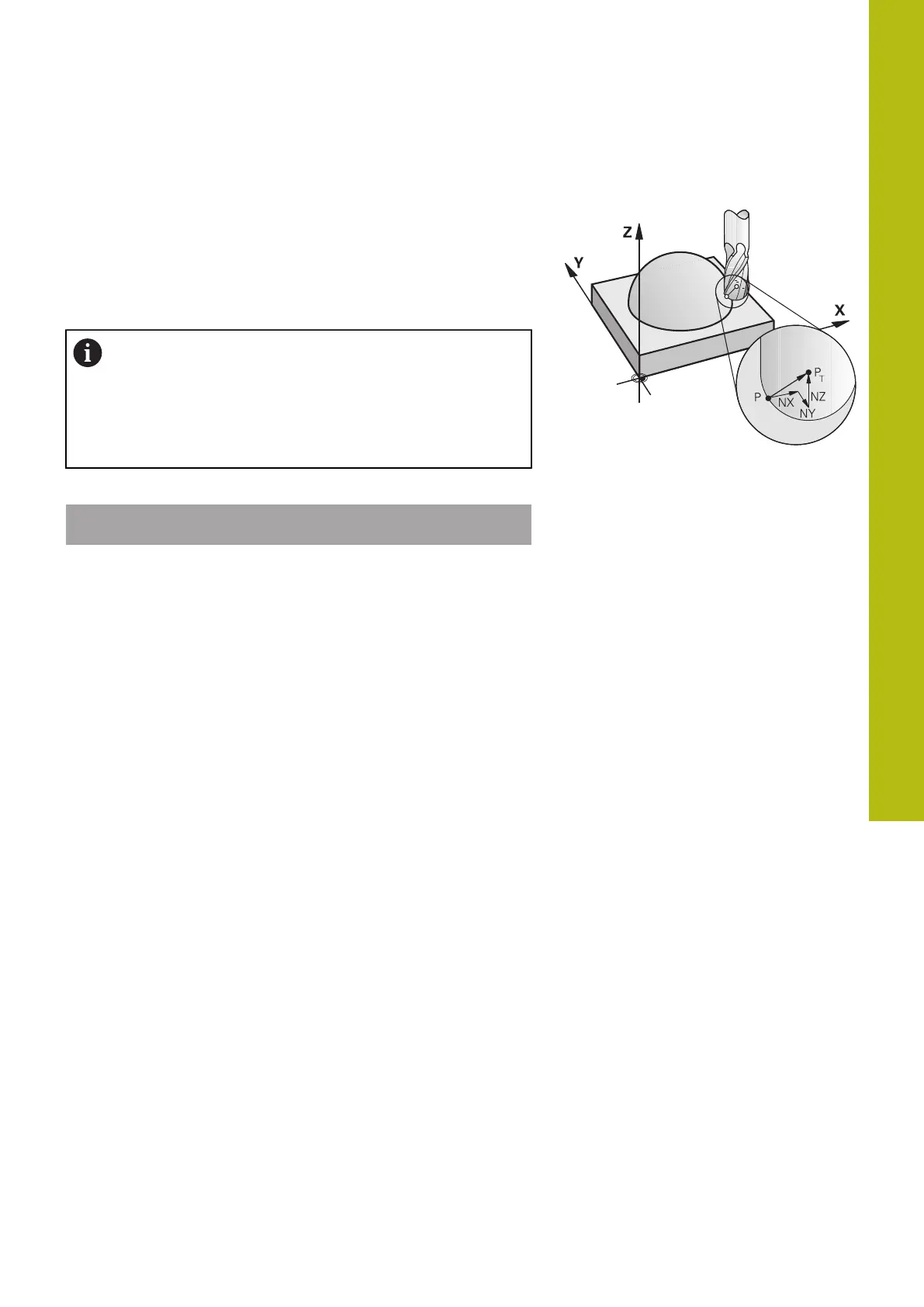

3-D compensation without TCPM

If the NC program includes surface normal vectors, the control

performs a 3-D compensation for three-axis machining. In this

case, the RL/RR radius compensation and TCPM or M128 must

be inactive. The control displaces the tool in the direction of the

surface-normal vectors by the total of the delta values (from the

tool table and TOOL CALL).

The control generally uses the defined delta values

for 3-D tool compensation. The entire tool radius R +

DR) is only taken into account if you have activated the

FUNCTION PROG PATH IS CONTOUR function.

Further information: "Interpretation of the programmed

path", page 588

Example: Block format with surface-normal vectors

1 LN X+31.737 Y+21.954 Z+33.165NX+0.2637581 NY+0.0078922

NZ-0.8764339 F1000 M3

LN:

Straight line with 3-D compensation

X, Y, Z:

Compensated coordinates of the straight-line

end point

NX, NY, NZ:

Components of the surface-normal vector

F:

Feed rate

M:

Miscellaneous function

Loading...

Loading...