13. IGNITION SYSTEM

SERVICE INFORMATION

TROUBLESHOOTING

IGNITION SYSTEM INSPECTION

IGNITION

COil

IGNITION CONTROL

MODULE

SERVICE INFORMATION

GENERAL

13-1

13·3

13-4

13

-7

13-7

ENGINE STOP SWITCH

IGNITION

TIMING

FLYWHEEl/STATOR

IGNITION SWITCH (AFTER 2000)

13-8

13-8

13·9

13-13

If

the

engine

must

be

running

to

do

som

e

work,

milk"

sure

the

ifrea ;s

well

ventilated. Never

run

the engine

in

an enclosed

area.

The

exhilus!

conreins

poisonous

I;

J

"oon

monoxide

gas

that

mar

cause 10M

of

consciousness

lind

mar

lead

to

death.

Run

th"

""gine

in

an

open

.rea

Or

wi

th an

exhaust

"

1I

,,eU/ltion

s!,.f/em

in

an

ene/asM

IIrea

.

CAUTION:

Som

e el

ec

trical

components

may

be

damaged

if

terminals

Of'

cotlnedors

IJre

connected

or

di$l;l)IInected

while

the

ignition

switch

is

ON

and

currenr

is

presen!.

This section covers serviCf! of the flywheel and

al

t

ernator

. Al l se

Nice

can

be

daM

with

the

engine

installed in the frame.

When

se

rvicing the

ignit

ion system, al

way

s

fo

ll

ow

the steps in the

tr

o

ubl

esh

ooting

sequence

on

page '

].].

T

he

ignition

timing does n

ot

nor

ma

lly need

10

be

ad

ju

sted since the

Igni

l

on

Contro

l ModUle (ICM) is fa<;tory

pr

ese

t. m

The

re

M may

be

damaged

if

dropped.

Also

if

the

conn

ector

is discon

ne<:

ted

when

current is

flo

wing.

th

e excessive

v

olt

age may

damage

t

he

modulo.

Always

t

urn

oN the engone

SlOP

switc

h befote

seNking.

A fau

lty

igni

ti

on

system

is

often

rolated to p

oor

connections.

C

h"

c

~

Those

connections b

ef

ore proceeding.

Use a spa

rk

plug

of tho

corrEiC

I heat

ra

nge. Using a spark plug with an oncorrect heal

ra

nge can damage the engine.

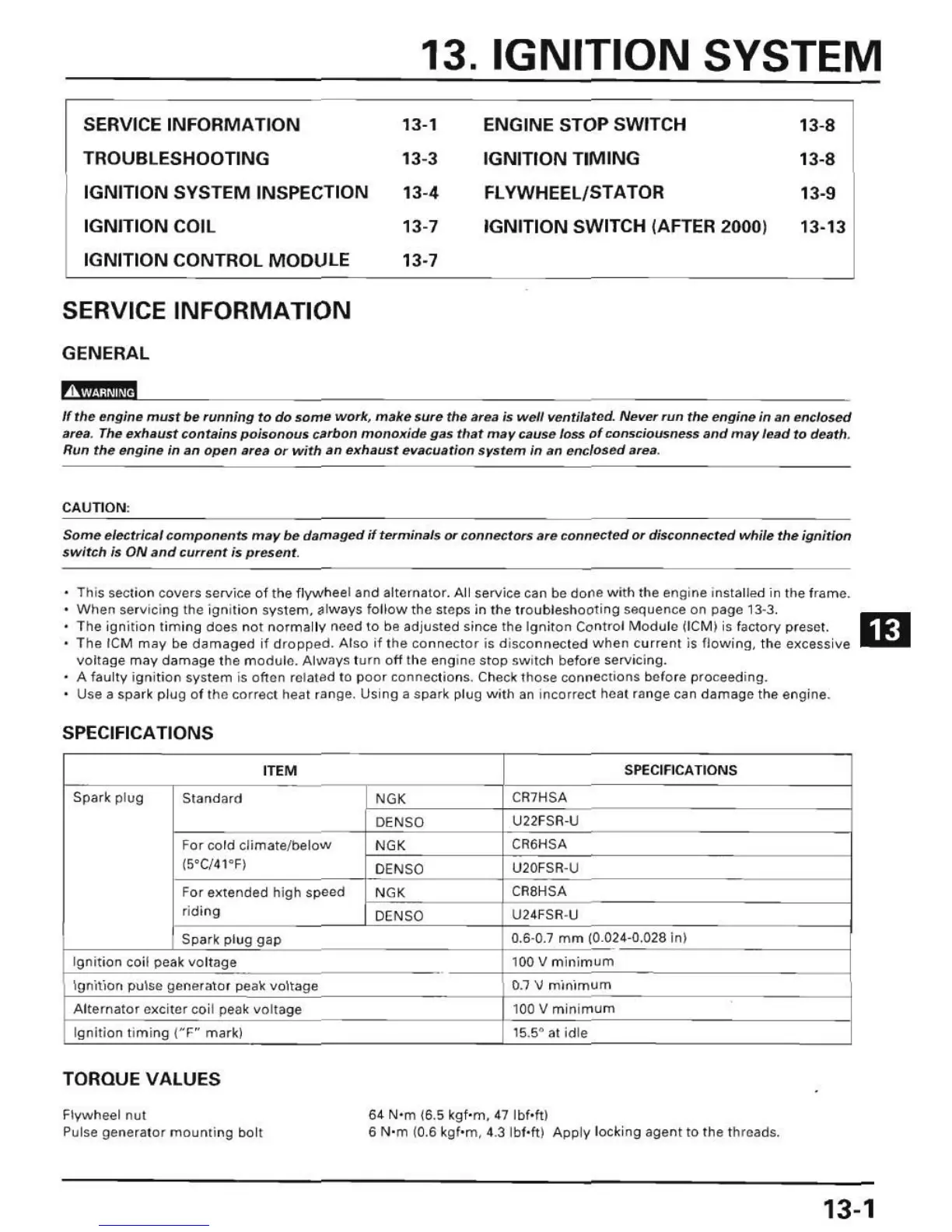

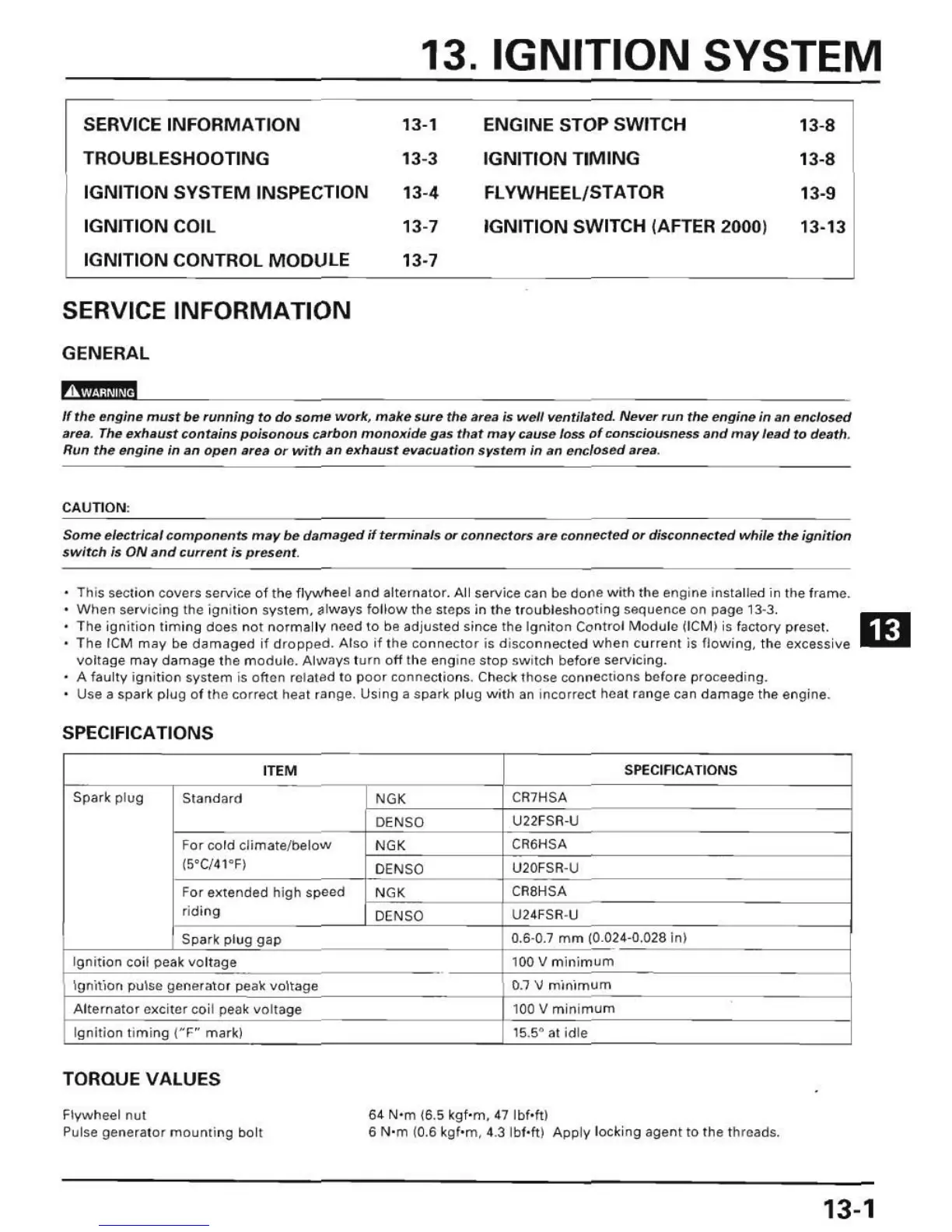

SPECIFICATIONS

ITEM

SPEC

IFIC

ATIONS

Spark plug

Standard

NG

K

CR7HSA

DE

NSO

U22FSR·U

For cold

clim

ate

/below

NG

K

CR6HSA

(5

°

C/

41°F)

OEN

se

U20FSR-U

For extended hi

gh

sp<led

NG

'

CR8HS

A

riding

DE

N

Se

U24

FSR

-U

Spa

rk

p

lu

g gap

0.6·0.7

mm (0.

02

4·0.028 in)

I

gnition

coil pe

ak

vo

lt

ag

e 100 V

mini

m

um

I

gnition

pulse genera

tor

peak voltage

0.1

'IJ

min

"

mum

Al

ternator

o

)(

citer

coil

peak

volta

ge 100 V

min

i

mum

I

gnition

tim ing

I"F

"

mar

kl

15

.

5·

at idle

TORQUE VALUES

Flywheel nut 64

N'

m (5.5 kgf·

m.l?

Ib

f·

ft)

Pulse

generat

or

mouming

b

oll

5

No

m

!C.6

k

gf

om. 4.3 I

bf·ft

) Apply locking agent

to

the threads.

13-1

Loading...

Loading...