12. Tighten the rear main bearing cap. Using the following method:

Preferred method:

a. Do the first step torque on the rear main bearing cap.

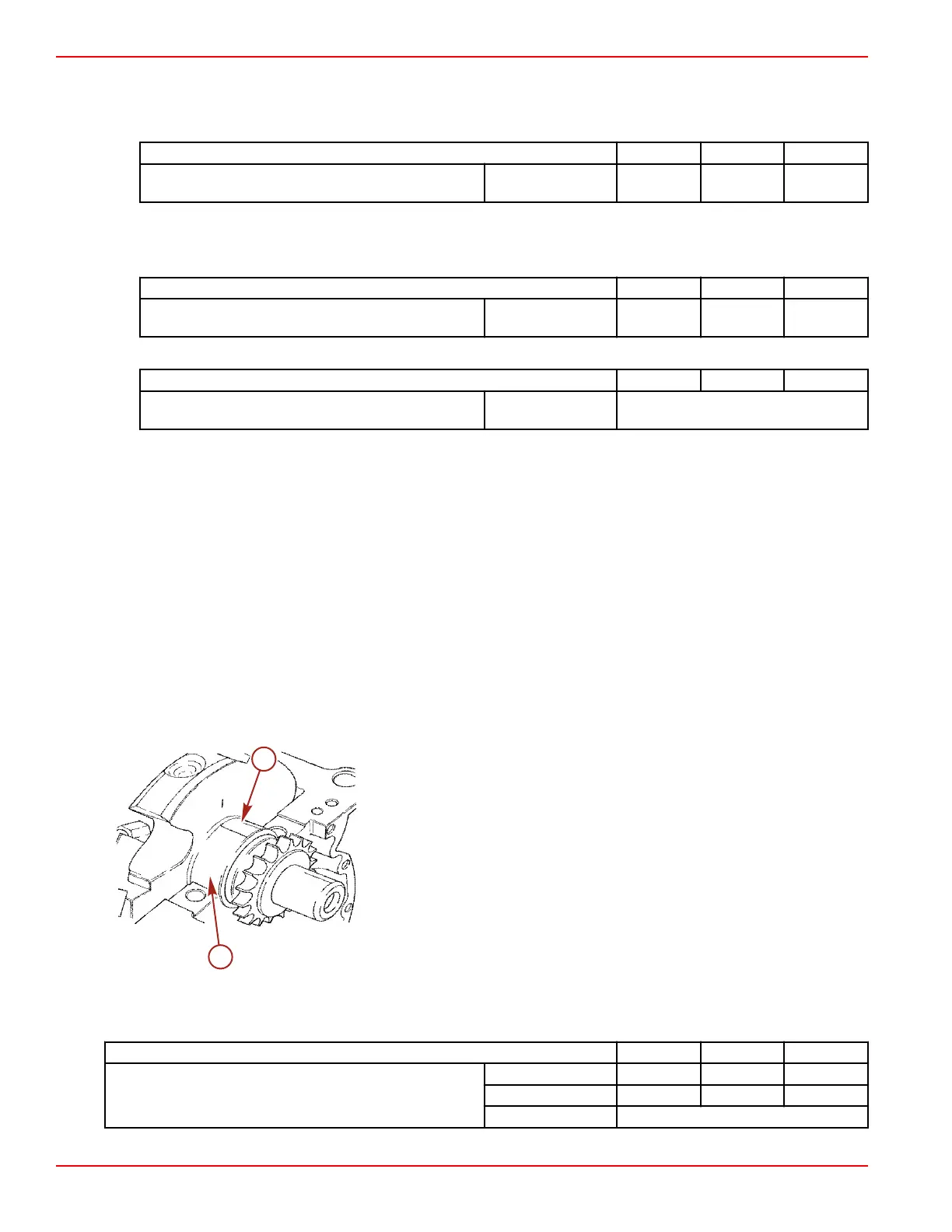

Description Nm lb‑in. lb‑ft

Crankshaft (main) bearing cap bolt—preferred

method

First

15 132.7 –

b. Using a lead hammer, tap the end of the crankshaft to the rear.

c. Using a lead hammer, tap the end of the crankshaft to the front.

d. Do the second step torque on the rear main bearing cap.

Description Nm lb‑in. lb‑ft

Crankshaft (main) bearing cap bolt—preferred

method

Second

40 – 29.5

e. Do the final step torque on the bearing cap.

Description

Nm lb‑in. lb‑ft

Crankshaft (main) bearing cap bolt—preferred

method

Final

+90°

13. Check the crankshaft end play.

14. Install the rear main seal retainer and seal.

15.

Check the clearance for each connecting rod bearing. Refer to Connecting Rod Bearing Clearance, Micrometer Method

or Connecting Rod Bearing Clearance, Plastigauge Method.

Main Bearing Clearance, Plastigauge Method

To obtain accurate measurements while using plastigauge or its equivalent, the engine must be out of the boat and upside

down so the crankshaft will rest on the upper bearings and the total clearance can be measured between the lower bearing and

journal.

To ensure the proper seating of the crankshaft, all bearing cap bolts should be at the specified torque. In addition, the surface

of the crankshaft journal and bearing must be wiped clean of oil.

NOTE: When checking the number 1 main bearing, loosen the accessory drive belt to prevent obtaining a tapered reading with

the gauging plastic.

1. Remove the bearing cap and wipe any oil from the journal and bearing cap to be inspected.

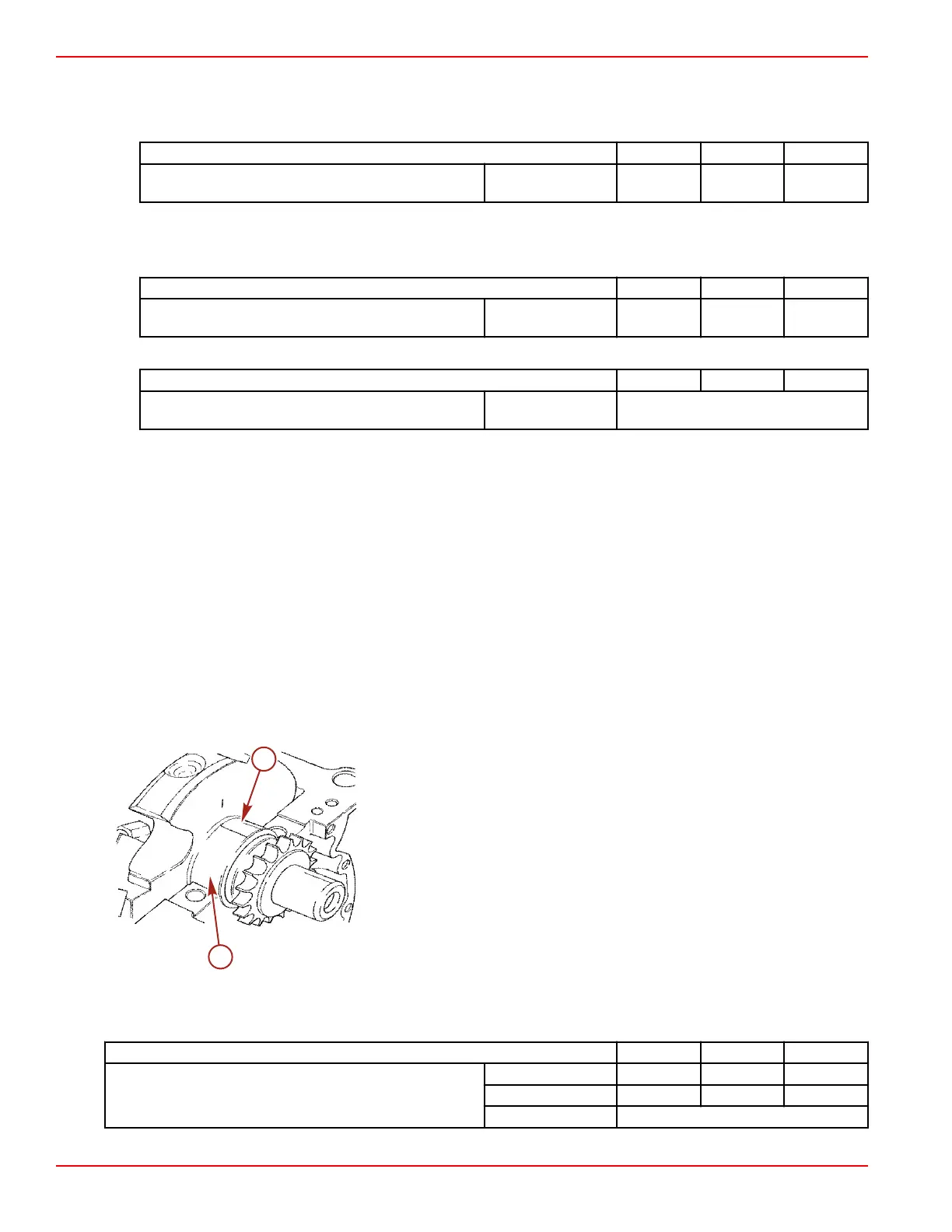

2. Place a piece of gauging plastic the full width of the bearing and parallel to the crankshaft centerline as shown.

Main bearing plastigauge measurement

a - Gauging plastic

b - Bearing journal

IMPORTANT: The bearing caps must be tightened to the specified torque to ensure correct measurements. Do not rotate

the crankshaft with the plastigauge installed.

3. Install the bearing cap and evenly tighten the main bearing cap bolt or stud to the specified torque.

Description

Nm lb‑in. lb‑ft

Crankshaft main bearing cap bolt—preferred method

First

15 132.7 –

Second

40 – 29.5

Final

+90°

4. Remove the bearing cap. The flattened gauging plastic will be found adhering to either the bearing cap or the journal.

Engine Inspection and Assembly

Page 3B-20 © 2016 Mercury Marine 90-8M0099748 eng DECEMBER 2015

Loading...

Loading...