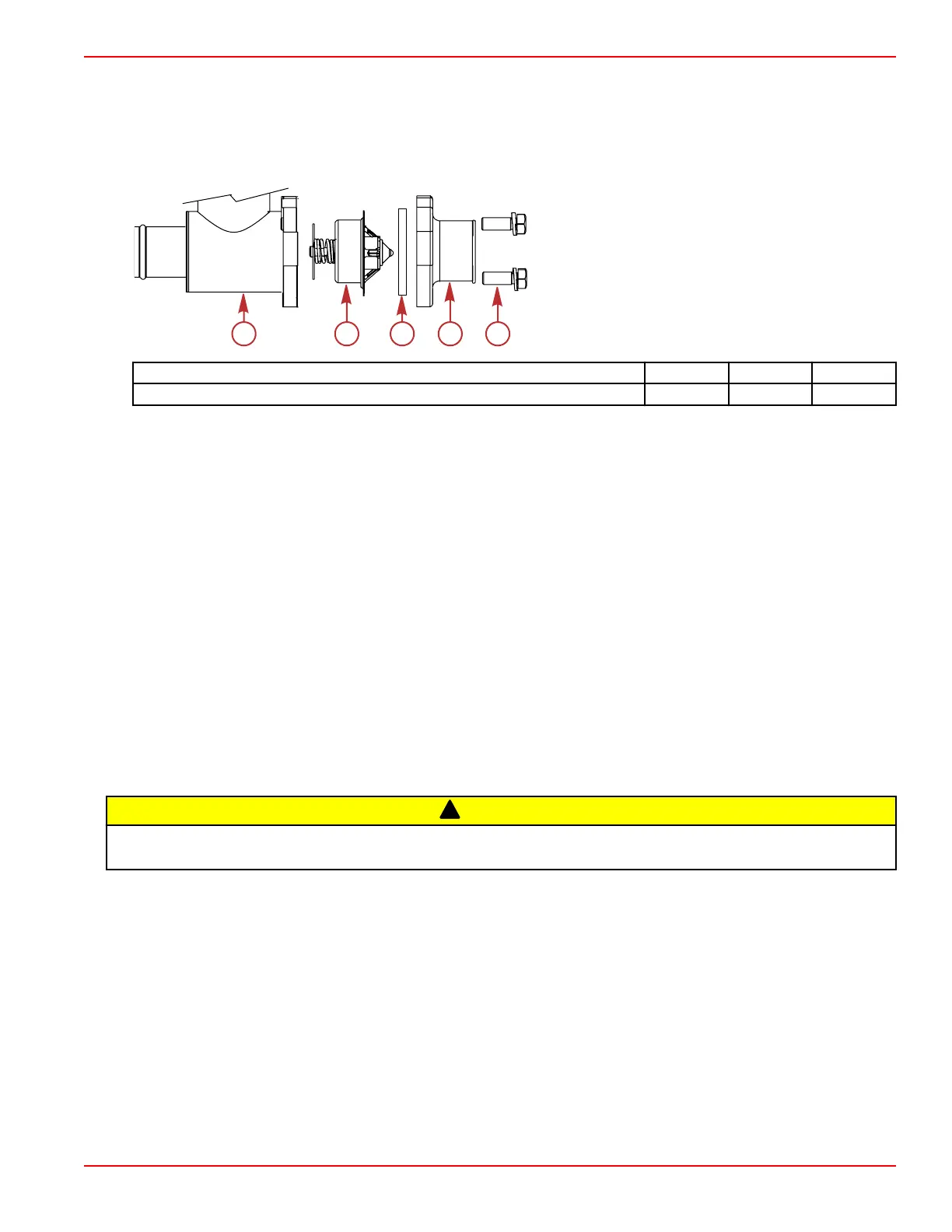

Thermostat Installation

1. Clean the surfaces on the thermostat housing and thermostat housing cover.

2. Install the thermostat seal onto the thermostat flange.

3. Install the thermostat into the thermostat housing.

4. Install the thermostat housing cover. Tighten the screws with captive lockwashers to the specified torque.

a - Thermostat housing (attached to heat

exchanger)

b - Thermostat

c - Thermostat seal

d - Thermostat housing cover

e - Screw with captive lockwasher (2)

Description Nm lb‑in. lb‑ft

Screw with captive lockwasher 6.8 60.1 –

5. Connect the hose to the thermostat housing cover. Tighten the hose clamp securely.

6. Connect any other hoses that were removed to gain access to the thermostat.

7. Fill the closed‑cooling system.

8. Supply cooling water, start the engine, and inspect for leaks.

Changing Coolant

Closed‑Cooling Section

The engine and exhaust sections of a closed‑cooling system should remain filled year‑round with the recommended coolant

solution. Do not drain the closed‑cooling section for storage, as this will promote rusting of internal surfaces. If the engine will

be exposed to freezing temperatures, fill the closed‑cooling section with Extended Life Coolant or an ethylene glycol antifreeze

and water solution. Follow the manufacturer's recommended proportions to protect the engine to the lowest temperature to

which it will be exposed. If necessary, change the coolant using the coolant specified in Coolant Recommendations.

Change Intervals

If the closed‑cooling system is factory installed, drain and flush the coolant from the closed‑cooling system at least every five

years or 1000 hours of operation, whichever comes first. Change the coolant whenever exhaust gases have entered the

system. If the system is not factory installed or has had anti‑freeze other than Extended Life Coolant added, it must be changed

every two years or 400 hours of operation, whichever comes first.

Draining the Closed Cooling System

!

CAUTION

A sudden loss of pressure can cause hot coolant to boil and discharge violently resulting in serious injury from burns. Allow

the engine to cool down before removing the coolant pressure cap.

IMPORTANT: A wire should be inserted into the drain holes to ensure that foreign material is not obstructing the drain holes.

IMPORTANT: The engine must be as level as possible to ensure the complete draining of the cooling system.

IMPORTANT: The closed‑cooling section must be kept filled year‑round with recommended coolant. If the engine will be

exposed to freezing temperatures, ensure that the closed‑cooling section is filled with Extended Life Coolant or an ethylene

glycol antifreeze and water solution properly mixed to protect the engine to the lowest temperature to which it will be exposed.

1. Remove the pressure cap from the coolant tank.

2. On the port and starboard sides of the engine block, remove the block pipe plugs. Drain the coolant into a proper container.

Models with Closed Cooling

90-8M0099748 eng DECEMBER 2015 © 2016 Mercury Marine Page 6C-15

Loading...

Loading...