IMPORTANT: Do not measure inside diameter close to the connecting rod and bearing split line.

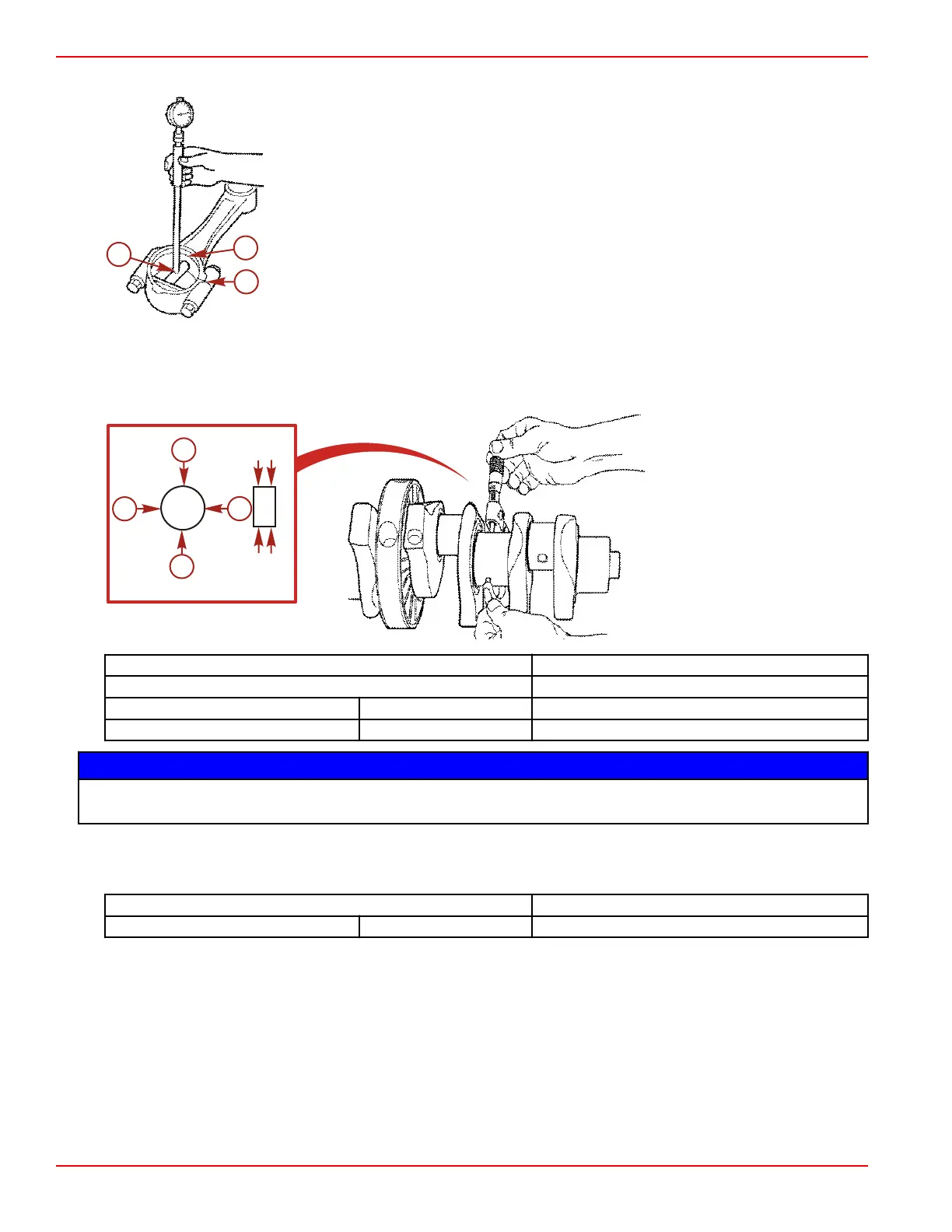

a - Inside dial indicator

b - Assembled rod and bearings

c - Split line

6. Record the measurements.

7. Wipe the crankshaft connecting rod journal with a clean cloth. Remove any oil film.

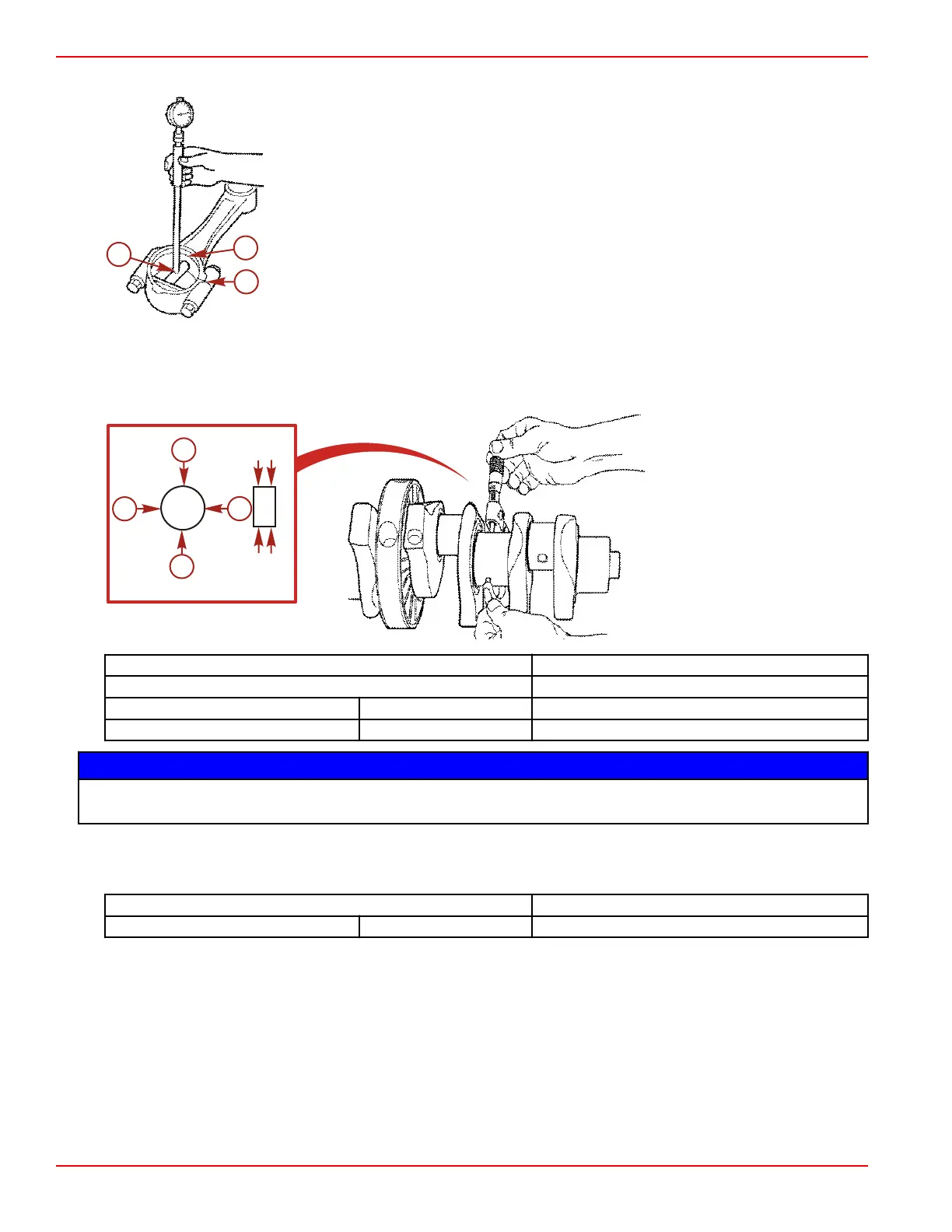

8. Measure the crankshaft connecting rod journal diameter with a micrometer. Take a second measurement at a position on

the connecting rod journal at a point 90° from the first measurement.

a - Measurement point "a"

b - Measurement point "b"

Description 6.2 Liter (377 cid)

Diameter 53.3095–53.3295 mm (2.0988–2.0995 in.)

Taper Production 0.005 mm (0.0002 in.) maximum

Out of round Production 0.008 mm (0.0003 in.) maximum

NOTICE

Inadequate clearance or interference between the bearing and its mating surface will result in rapid bearing wear and

catastrophic component failure. Check all bearing clearances.

9. If the crankshaft rod bearing journal diameters are not within specifications, replace or recondition the crankshaft.

10. If the crankshaft rod bearing journal diameters are within specifications, determine bearing clearance by subtracting the

crankshaft connecting rod journal outer diameter from the inner diameter of the bearing from step 5.

Description

6.2 Liter (377 cid)

Clearance Production 0.047–0.110 mm (0.0019–0.0043 in.)

11. If the clearance exceeds specifications, select a new, correct size bearing, and recheck the bearing clearance.

Connecting Rod Bearing Clearance, Plastigauge Method

The plastic gauge method is an optional method of determining connecting rod bearing clearance. Micrometer measurement is

the preferred method.

1. Wipe both upper and lower bearings and the crankshaft connecting rod journal with a clean soft cloth. Remove any oil film.

2. Install the bearings in the connecting rod and cap.

IMPORTANT: To obtain accurate measurements the connecting rod and upper bearing must be seated against the

connecting rod journal before installing the lower bearing and rod cap.

3. Rotate the crankshaft or move the connecting rod until the upper bearing is fully seated against the connecting rod journal

being measured.

Engine Inspection and Assembly

Page 3B-30 © 2016 Mercury Marine 90-8M0099748 eng DECEMBER 2015

Loading...

Loading...