Removal

IMPORTANT: Follow the recommendations of the fuel pressure gauge manufacturer for the correct procedure for relieving

pressure from the system.

1. Relieve the pressure from the fuel system.

2. Remove the fuel pressure gauge from the engine.

3. Install the Schrader valve cap.

Checking for Restrictions/Vapor Lock Problems in Fuel Delivery Systems

If there are any restrictions in the fuel delivery system the engine may experience vapor lock and other driveability problems.

Fuel supply problems can be checked by using a vacuum gauge on a water‑separating fuel filter fitting port. Installing it on the

inlet side will check the fuel tank to filter supply line and hardware (anti‑siphon valve, fuel fittings, etc.). Installing it on the outlet

side will check the supply line, hardware, and the filter. If the outlet vacuum reading is higher than the inlet reading, the filter is

clogged. If both readings are high then inspect the fuel tank, supply line, and hardware. Check for debris in the tank (blocking

the pickup), clogged fuel filter screens on the end of pickup tubes in the tank, clogged in‑line fuel filters, blocked off fuel tank

vent, bent pickup tube, dirt and debris in the fuel fittings, wrong size fuel fittings (undersize connector fittings, undersize fuel

shut‑off valve passages, etc.), undersize fuel line, or a malfunctioning anti‑siphon valve.

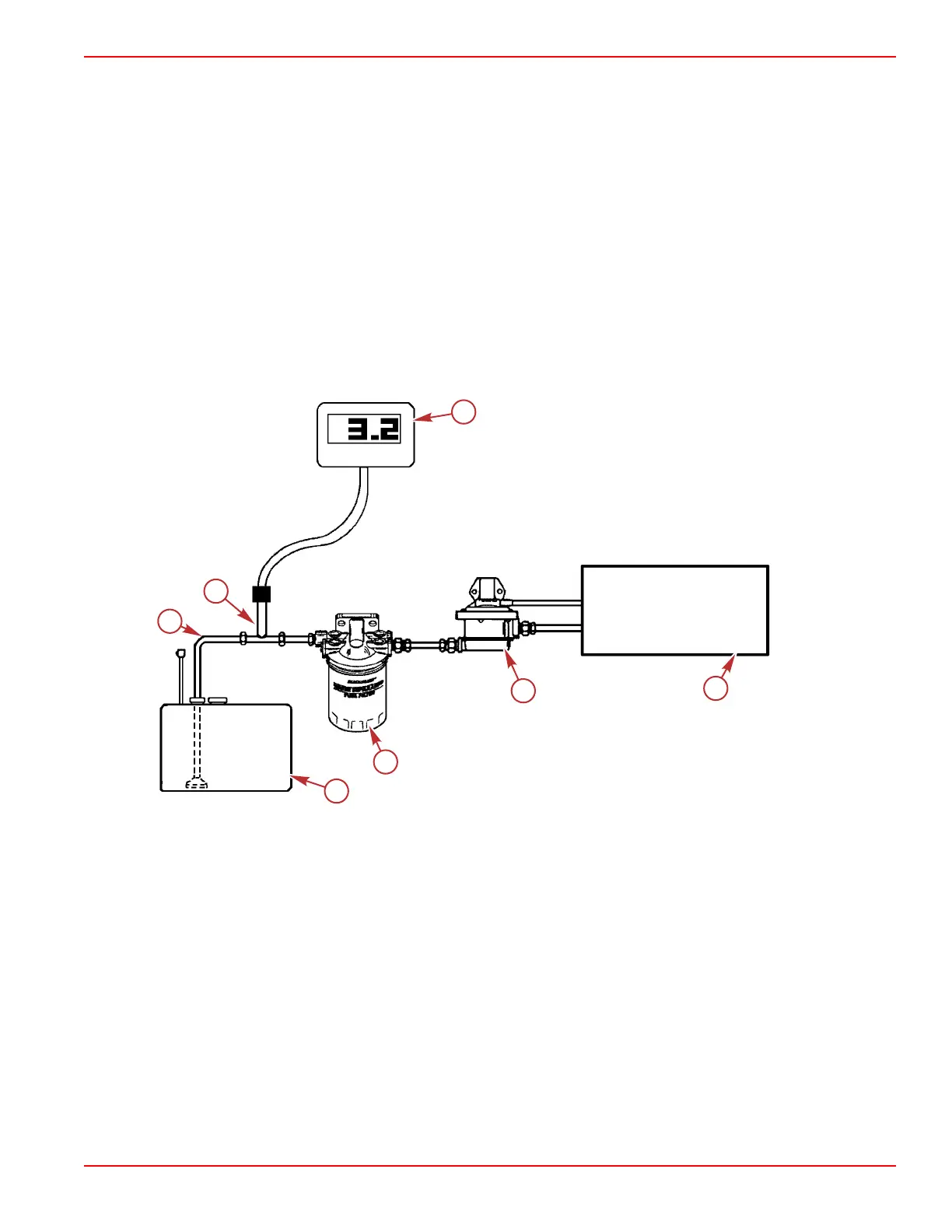

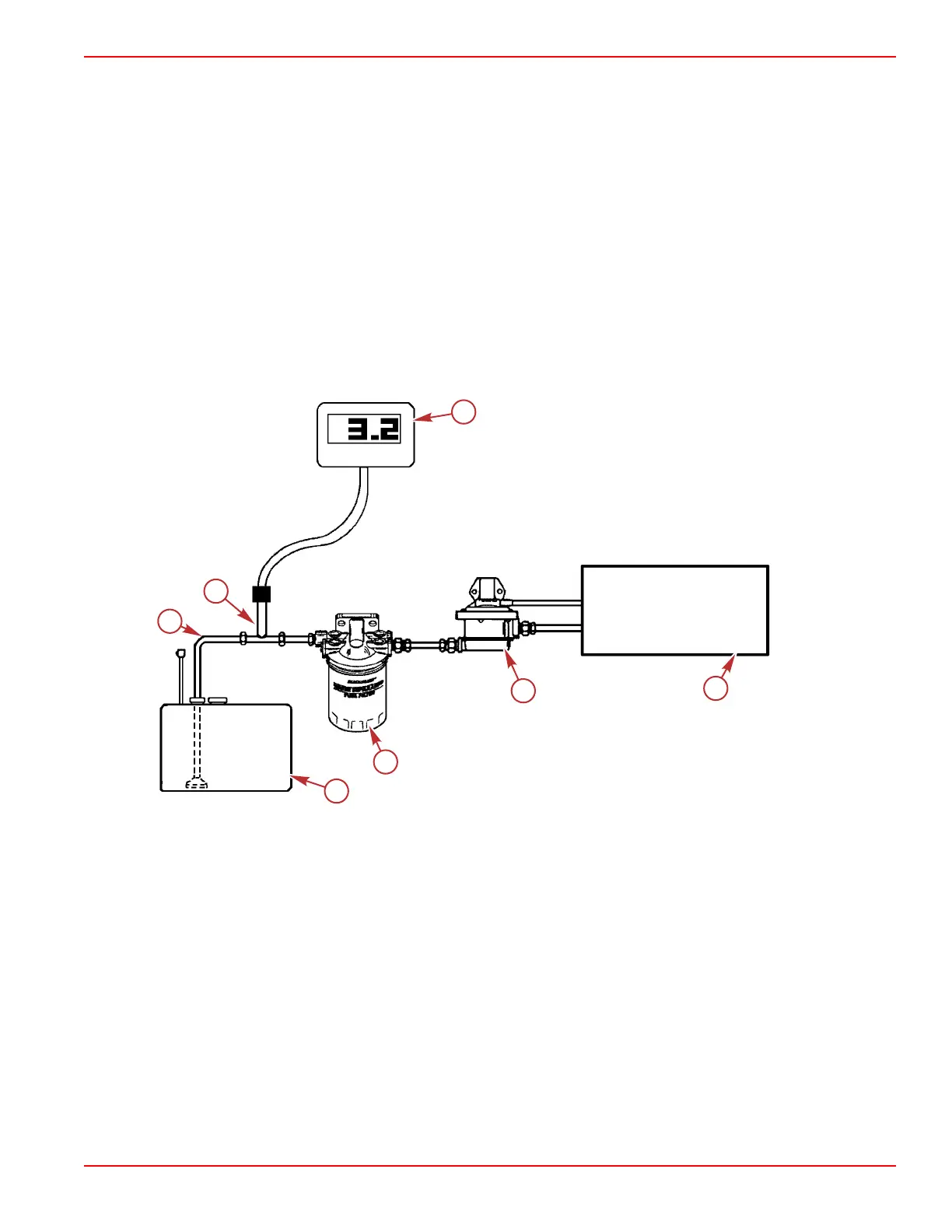

a - Fuel tank

b - Clear hose can be used to check for air bubbles

c - T‑fitting

d - Digital vacuum gauge

e - Water‑separating fuel filter

f - Fuel pump (mechanical or electric ‑ depending on fuel system)

g - EFI fuel system

There is a MerCruiser specification for allowable vacuum, when measured at the inlet side of the engine‑mounted MerCruiser

water‑separating fuel filter or if there is none mounted on the engine, at the inlet side of a fuel pump. Use a digital vacuum

gauge (an analog gauge may not give accurate enough readings at these low levels) that reads in either kPa (kilopascals) or in.

Hg (inches of mercury).

The specification is: 7 kPa (2 in. Hg) maximum at: idle, 3000 RPM, full throttle and then back at idle RPM (check at each point).

Any anti‑siphon valve or restriction that causes a higher reading can contribute to vapor locking and other driveability problems.

In hot weather, if you see 0 vacuum on the gauge and the engine is still running poorly, check the inlet fuel line to ensure that a

good solid flow of fuel is in the line, instead of a mixture of fuel and vapors. If the vacuum is too high, try a less restrictive

anti‑siphon valve. Restrictive anti‑siphon valves can cause vapor locking conditions.

MPI ECT Fuel System

90-8M0099748 eng DECEMBER 2015 © 2016 Mercury Marine Page 5A-31

Loading...

Loading...