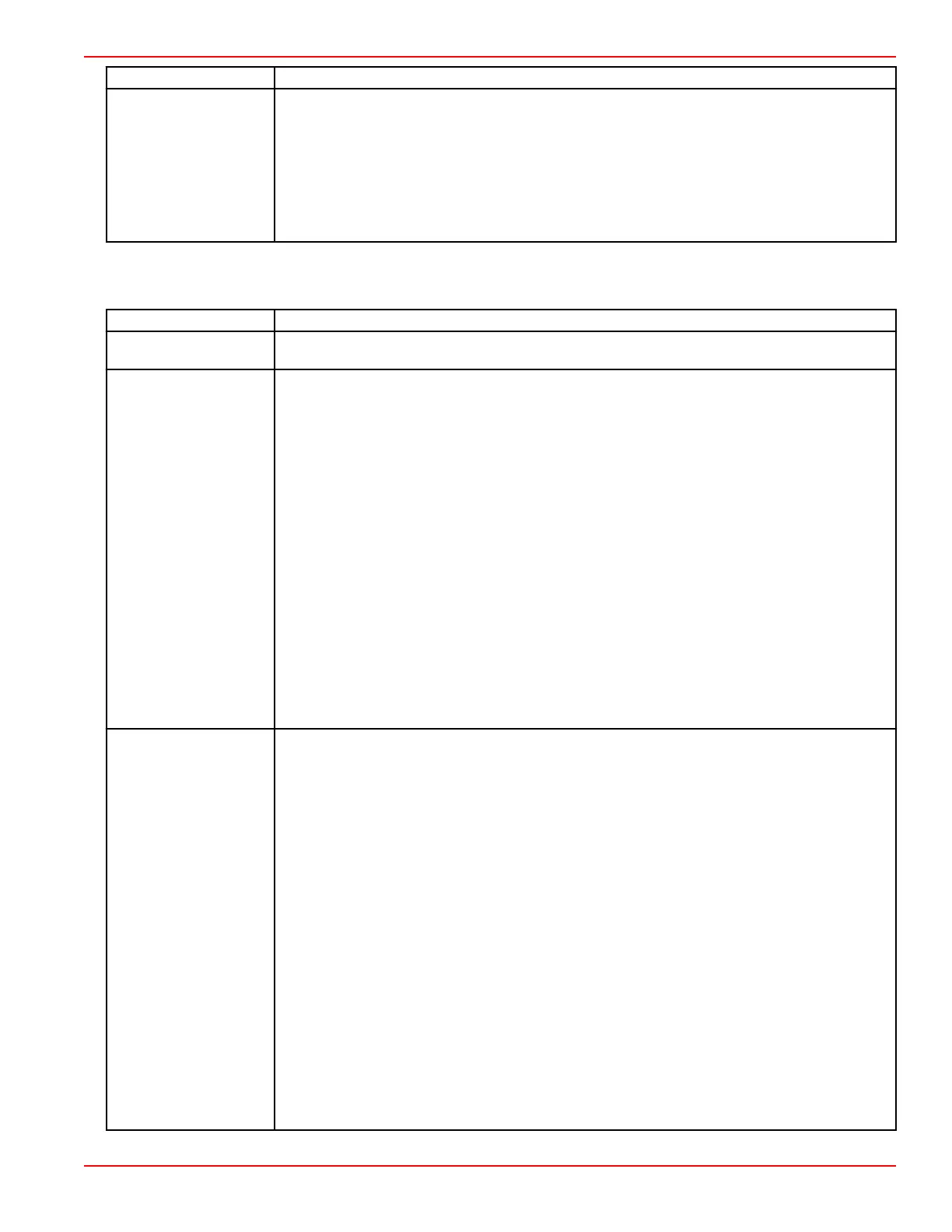

Task Interval Maintenance to Be Performed

Every two months or 50

hours of operation

• Remove the propeller and lubricate the propeller shaft and torque the nut. (If operating only in

freshwater, you can extend the interval to every four months.)

• If operating in saltwater, brackish water, or polluted water, apply Corrosion Guard to the

power package.

• Check the battery connections and the fluid level.

• Ensure that the gauges and the wiring connections are secure. Clean the gauges. (If

operating in saltwater, reduce this interval to every 25 hours or 30 days, whichever occurs

first.)

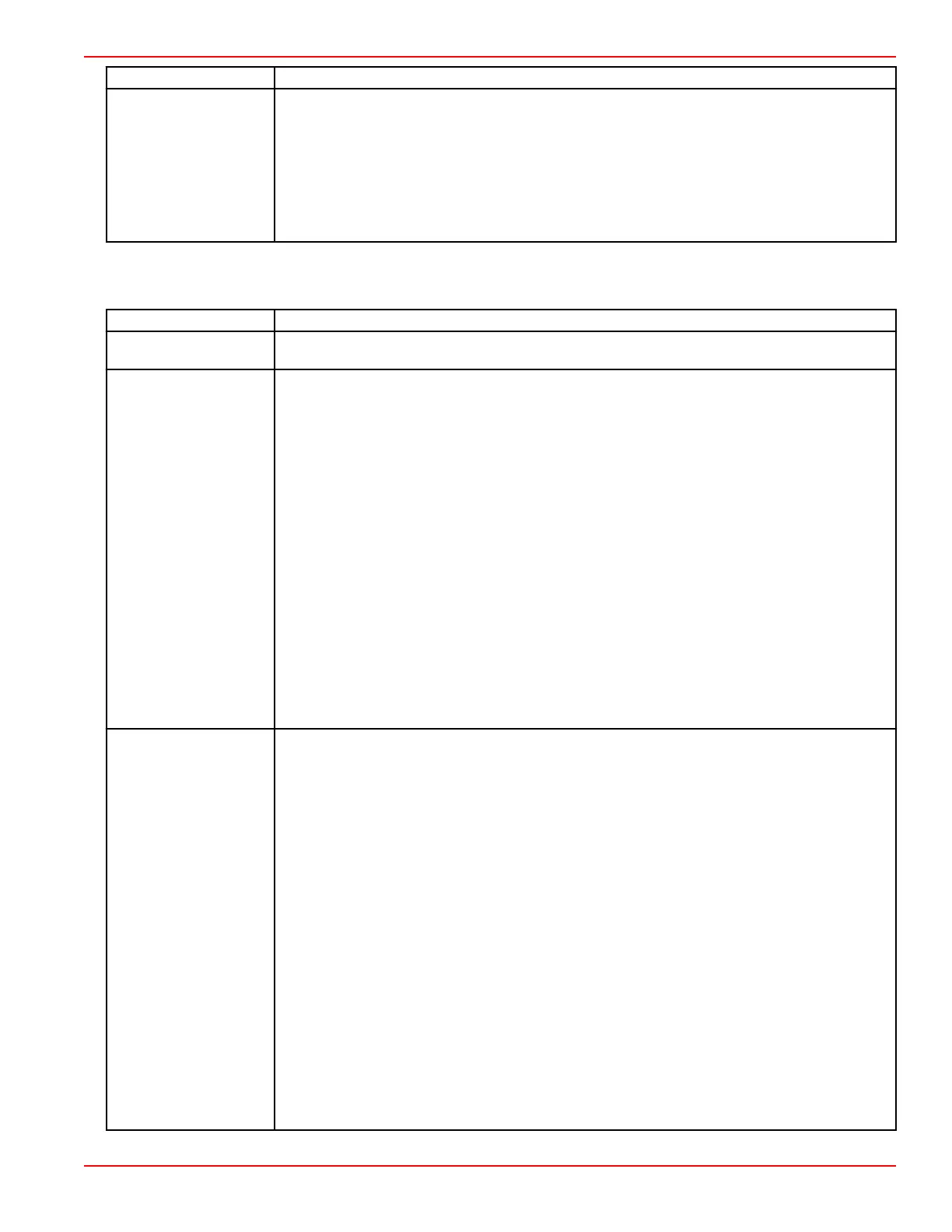

Scheduled Maintenance

NOTE: Only perform maintenance that applies to your particular power package.

Task Interval

Maintenance to Be Performed

50 hours or 2 months

(whichever occurs first)

Lubricate the engine coupler. (If operated at idle for prolonged periods of time, lubricate the

coupler every 50 hours.

Every 100 hours or

annually

(whichever occurs first)

• Touch‑up the paint on the power package.

• Change the engine oil and filter.

• Change the sterndrive gear lube.

• If the condition of the spark plugs and spark plug wires was satisfactory at the initial inspection

(as listed in Every 300 hours or 3 years), inspect the condition of these components.

Replace as necessary.

• On models with closed‑cooling, check the coolant level and antifreeze concentration for

adequate freeze protection. Correct if necessary. Refer to the Specifications section.

• Tighten the connection of the gimbal ring to the steering shaft to specifications.

• Inspect the water‑separating fuel filter and replace if debris is visible.

• Check the steering system and the remote control for loose, missing, or damaged parts.

Lubricate the cables and the linkages.

• Check the continuity circuit for loose or damaged connections. Test the MerCathode unit

output if equipped.

• Inspect the condition and the tension of the belt.

• Driveshaft extension models: Lubricate the driveshaft U‑joints and tailstock input and output

bearings.

• Inspect the PCV valve and replace if necessary.

Every 300 hours or 3

years

• Check the engine mounts for tightness and torque if necessary.

• Check the electrical system for loose, damaged, or corroded fasteners.

• Clean the flame arrestor and the crankcase ventilation hoses.

• Inspect the condition of the spark plugs and spark plug wires. Replace as necessary. If the

condition of these components is satisfactory at inspection, repeat inspection every 100 hours

or once a year, whichever occurs first.

• Check the cooling system and the exhaust system hose clamps for tightness. Inspect both

systems for damage or leaks.

• Disassemble and inspect the seawater pump and replace worn components.

• On models with closed‑cooling, clean the seawater section of the closed‑cooling system.

Clean, inspect, and test the pressure cap.

• Inspect the exhaust system components. If the package was equipped with water shutters

(flapper valves), verify that they are not missing or worn.

• Check the engine alignment.

• Inspect the U‑joints, the splines, and the bellows, and check the clamps.

• Lubricate the U‑joint splines and cross bearing.

• Inspect the gimbal bearing for roughness. Replace if necessary. See your certified Mercury

MerCruiser dealer.

• Lubricate the engine coupler.

• Replace the vent valve on each exhaust elbow (port and starboard).

Maintenance

90-8M0099748 eng DECEMBER 2015 © 2016 Mercury Marine Page 1C-7

Loading...

Loading...