Closed‑Cooling System

Checking Coolant Level

!

CAUTION

A sudden loss of pressure can cause hot coolant to boil and discharge violently resulting in serious injury from burns. Allow

the engine to cool down before removing the coolant pressure cap.

1. Remove the cap from the heat exchanger and observe the fluid level.

2. The coolant level in the heat exchanger should be at the bottom of the filler neck.

IMPORTANT: When reinstalling the pressure cap, tighten it until it seats on the filler neck.

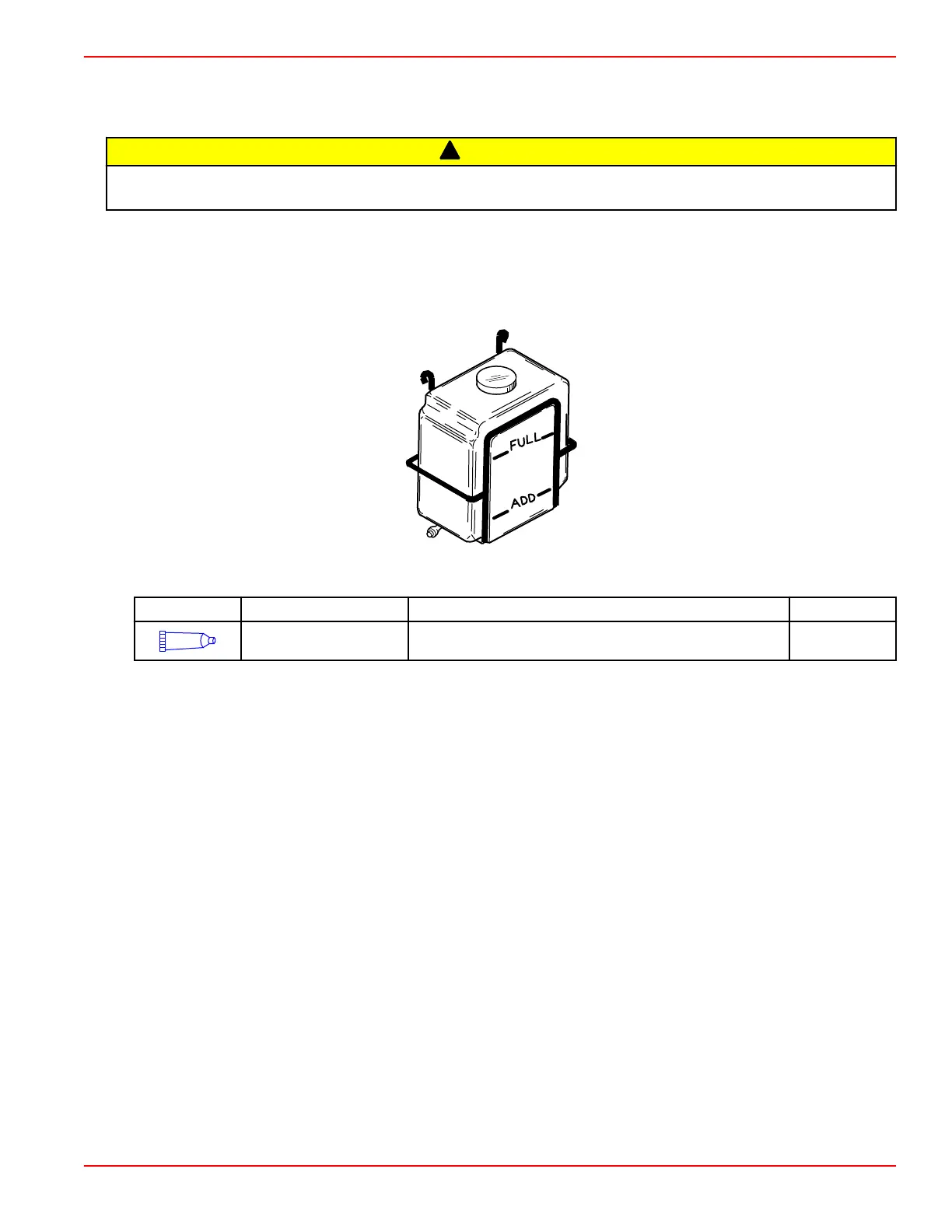

3. With the engine at normal operating temperature, check the coolant level in the coolant recovery bottle.

4. The coolant level should be between the "ADD" and "FULL" marks.

6102

5. Add the specified fluid as necessary.

Tube Ref No.

Description Where Used Part No.

122

Extended Life Antifreeze/

Coolant

Closed-cooling system 92-877770K1

Cleaning and Inspection

NOTE: Refer to

Section 6C

.

1. Ensure that all hose clamps are tight and connections are secure.

2. Inspect the entire system for damage or leaks.

3. Clean the seawater section.

4. Clean, inspect and test the pressure cap.

Changing Coolant

The coolant should be changed periodically based on the use of the specified coolant; refer to the Maintenance Schedules for

the interval. For the coolant changing procedures, refer to Section 6C.

Power‑Assisted Steering Fluid

Power‑Assisted Steering Fluid—Sterndrive only

Checking

Engine at Normal Operating Temperature

1. Stop the engine.

2. Center the sterndrive.

Maintenance

90-8M0099748 eng DECEMBER 2015 © 2016 Mercury Marine Page 1C-19

Loading...

Loading...