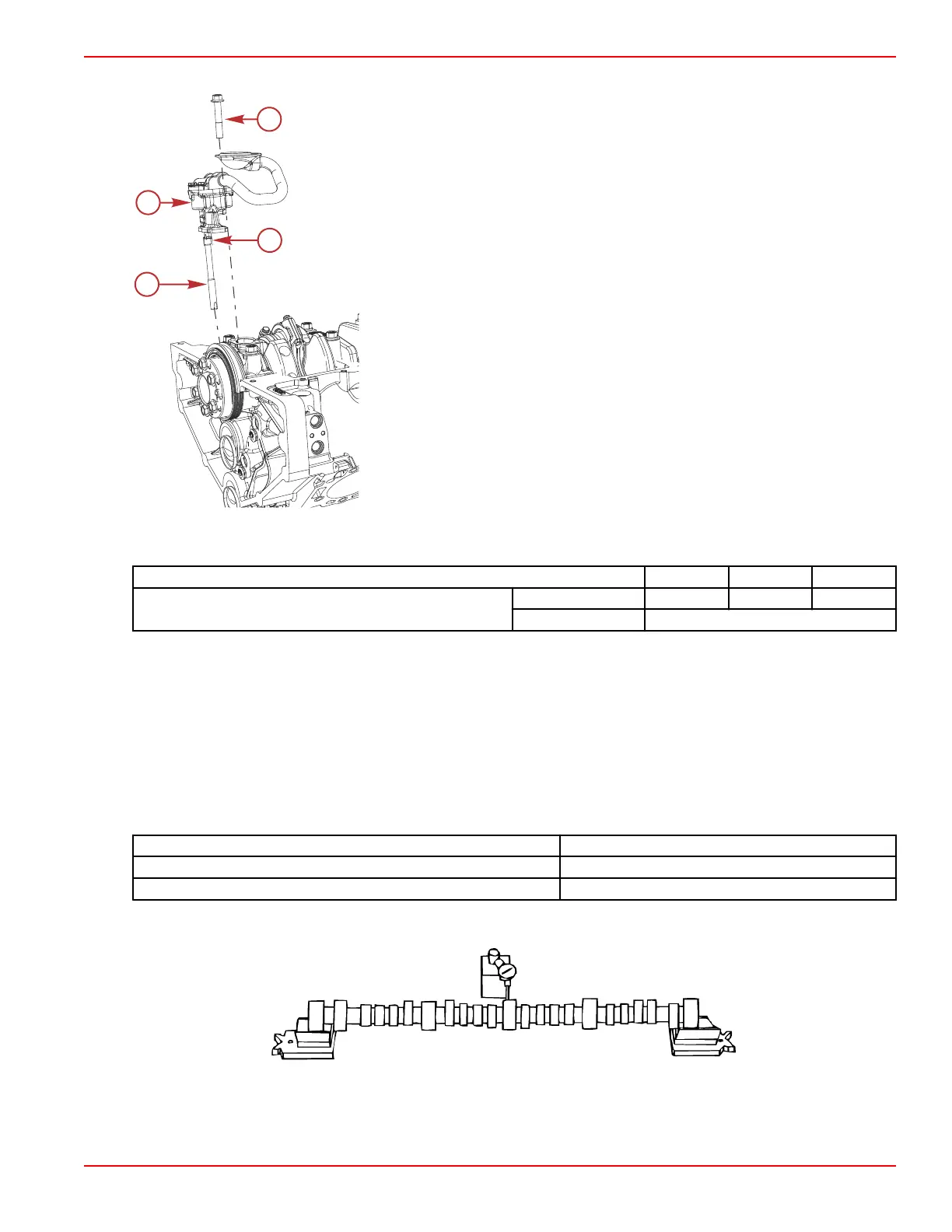

IMPORTANT: Do not reuse the oil pump driveshaft retainer.

a - Driveshaft

b - Driveshaft retainer

c - Oil pump

d - Screw

2. Install the oil pump driveshaft, a new driveshaft retainer, and the oil pump to the rear main bearing cap.

3. Tighten the oil pump screw to the specified torque.

Description

Nm lb‑in. lb‑ft

Oil pump screw (to rear crankshaft bearing cap)

First

20 177 –

Final

+65°

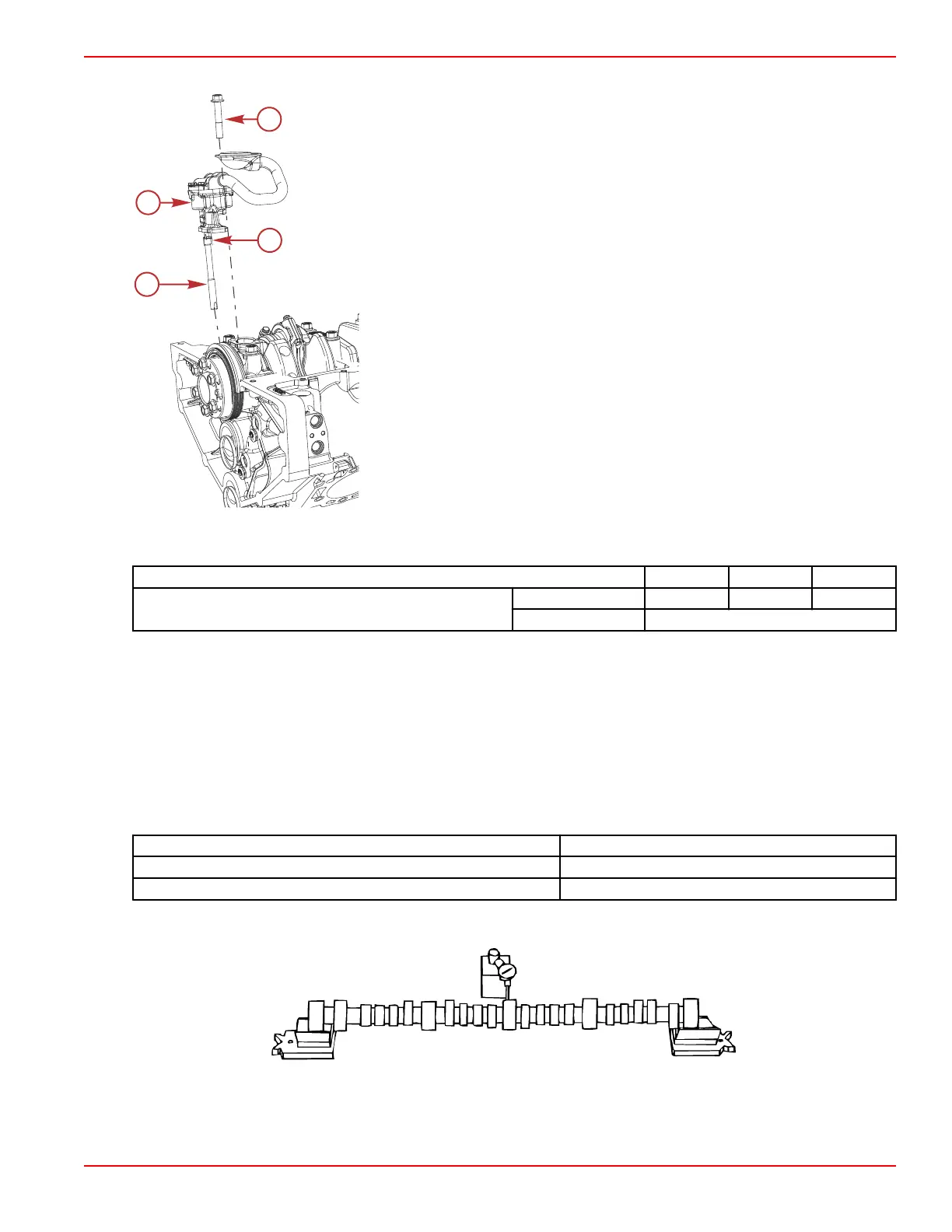

Camshaft

Inspection

1. Inspect the camshaft thrust plate for damage. Replace if damaged or worn.

2. Inspect the camshaft for worn, scored, or damaged bearing journals or lobes.

3. Inspect the camshaft for bolt hole threads.

4. Inspect the camshaft sprocket locator pin.

5. Measure the camshaft bearing journals with a micrometer. If journals are not within specifications, the camshaft should be

replaced.

Description 6.2 Liter (377 cid)

Journal diameter 47.465–47.490 mm (1.8687–1.8697 in.)

Journal out of round 0.05 mm (0.0020 in.) maximum

6. Measure for a bent camshaft or excessive camshaft runout with a dial indicator. If the runout exceeds the specified

amount, the camshaft should be replaced.

Checking camshaft alignment

Engine Inspection and Assembly

90-8M0099748 eng DECEMBER 2015 © 2016 Mercury Marine Page 3B-33

Loading...

Loading...