5. On the edge of the gauging plastic envelope there is a graduated scale that is correlated in thousandths of an inch. Without

removing the gauging plastic from the crankshaft bearing or journal, measure its compressed width at the widest point with

the graduated scale.

NOTE: Normally main bearing journals wear evenly and are not out of round.

• If a bearing is being fitted to an out of round journal of 0.0254 mm (0.001 in.) maximum, be sure to fit to the maximum

diameter of the journal.

• If the bearing is fitted to the minimum diameter and the journal is out of round 0.0254 mm (0.001 in.) maximum,

interference between the bearing and journal will result in rapid bearing failure.

• If the flattened gauging plastic tapers toward the middle or ends, the difference in clearance indicates taper or another

irregularity of the bearing or journal.

• Measure the journal with a micrometer if the flattened gauging plastic indicates more than 0.0254 mm (0.001 in.)

difference.

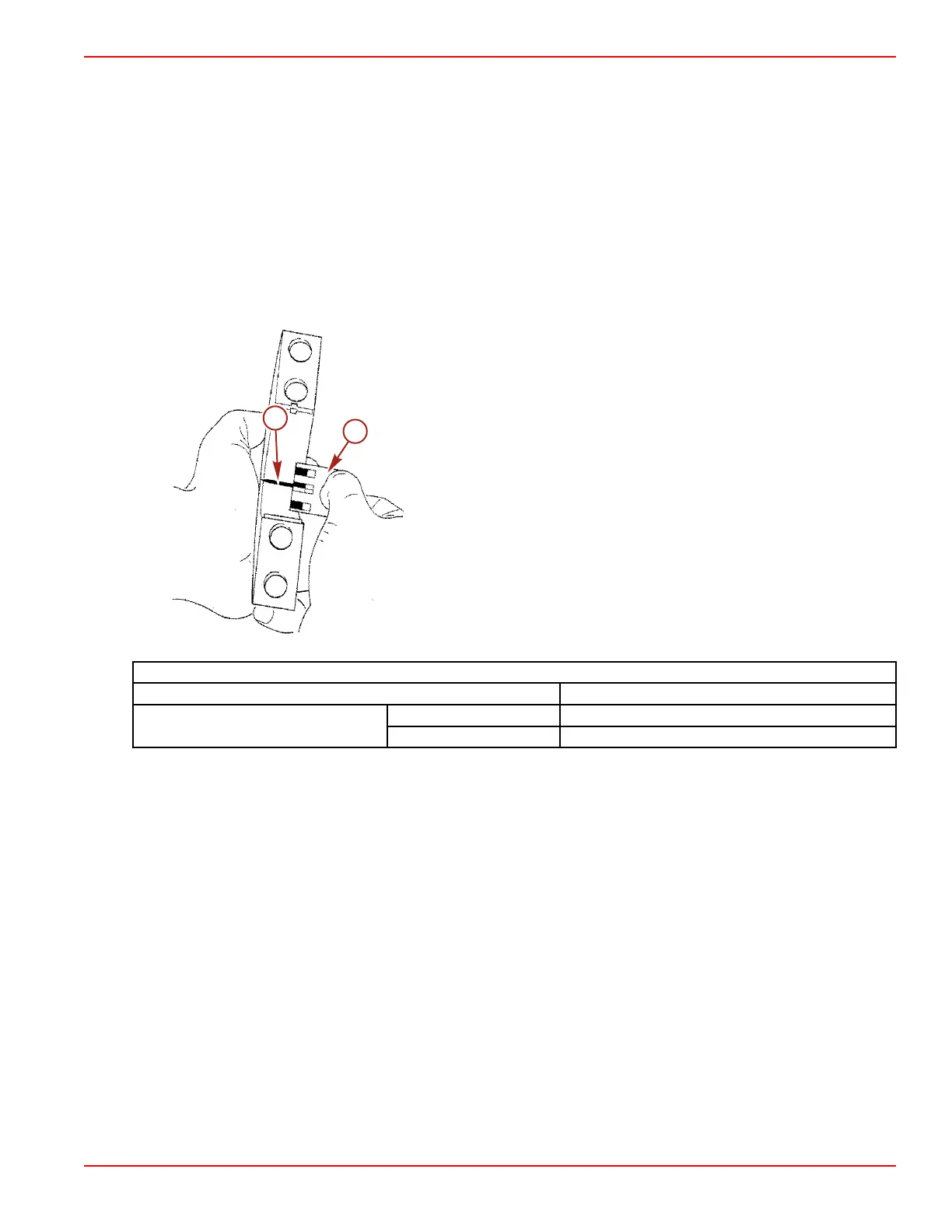

Measuring clearance with plastigauge

a - Compressed gauging plastic

b - Scale

Main Bearing Clearance

Description 6.2 Liter (377 cid)

Production

Number 1, 2, 3, 4 0.043–0.107 mm (0.0017–0.0042 in.)

Number 5 0.043–0.107 mm (0.0017–0.0042 in.)

6. If the bearing clearance is within specifications, the bearing insert is satisfactory. If the clearance is not within

specifications, replace the insert. Always replace both upper and lower inserts as a set.

7. A standard or 0.0254 mm (0.001 in.) undersized bearing may produce the proper clearance. If not, it will be necessary to

regrind the crankshaft journal for use with the next undersized bearing.

IMPORTANT: After selecting a new bearing, recheck clearance.

8. Check clearance with a newly selected bearing. If the bearing clearance is within specifications, the bearing insert is

satisfactory. If not, repeat previous steps.

9. Proceed to the next bearing. After all bearings have been checked, oil and install the selected bearings and rotate the

crankshaft to check for excessive drag.

Crankshaft End Play

1. Firmly force the crankshaft rearward.

2. Firmly force the crankshaft forward.

Engine Inspection and Assembly

90-8M0099748 eng DECEMBER 2015 © 2016 Mercury Marine Page 3B-21

Loading...

Loading...