Second Compression

Description 6.2 Liter (377 cid)

Groove clearance Production 0.020–0.060 mm (0.0008–0.0023 in.)

Oil Control

Description 6.2 Liter (377 cid)

Groove clearance Production 0.020–0.165 mm (0.0008–0.0065 in.)

7. Replace the piston if groove clearance exceeds the specified limit.

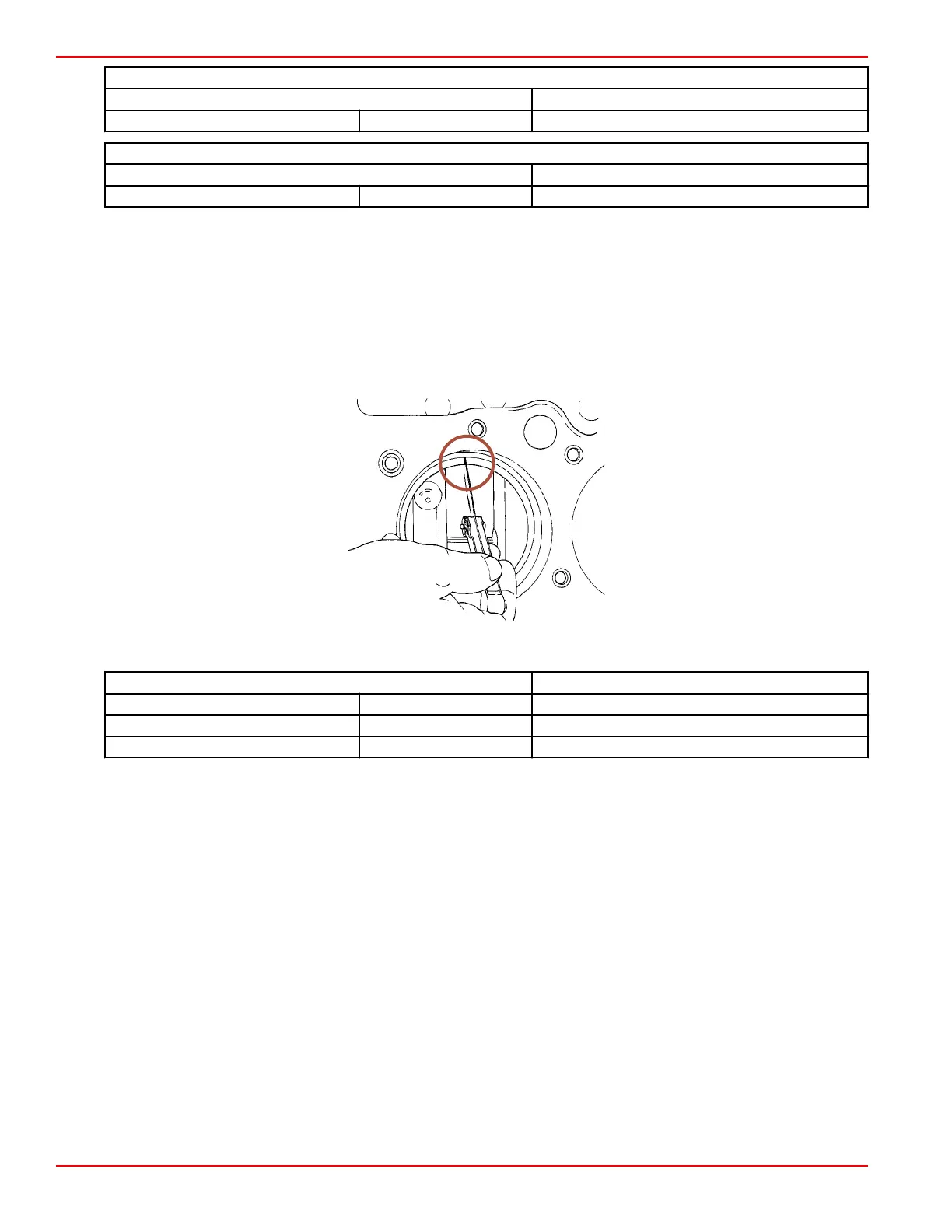

Piston Ring Gap Inspection

IMPORTANT: Fit each compression ring to the cylinder in which it is going to be used.

1. Insert a piston ring into the cylinder bore.

2. Use an inverted piston to push the piston ring 6 mm (1/4 in.) into the cylinder bore.

NOTE: Ensure that the piston and ring are square with the cylinder wall.

3. Remove the piston.

4. Using a feeler gauge, measure the piston ring gap.

Measuring piston ring gap

Description 6.2 Liter (377 cid)

Top compression ring gap Production 0.38–0.52 mm (0.015–0.020 in.)

Second compression ring gap Production 0.63–0.82 mm (0.025–0.032 in.)

Oil control ring gap Production 0.18–0.72 mm (0.007–0.028 in.)

5. Replace the ring if the gap exceeds service limits. If the ring gap is below specifications, remove the ring and try another.

Assembly

Piston Ring Installation

IMPORTANT: All compression rings are marked on the upper side of the ring. When installing compression rings, ensure that

the marked side is toward the top of the piston.

NOTE: Oil control rings are a three‑piece type, consisting of two rings and a spacer.

1. Select rings appropriate for the cylinder bore and piston size.

2. Install the oil control ring spacer in its groove.

Engine Inspection and Assembly

Page 3B-24 © 2016 Mercury Marine 90-8M0099748 eng DECEMBER 2015

Loading...

Loading...