ENGINE

3-16

EAS21080

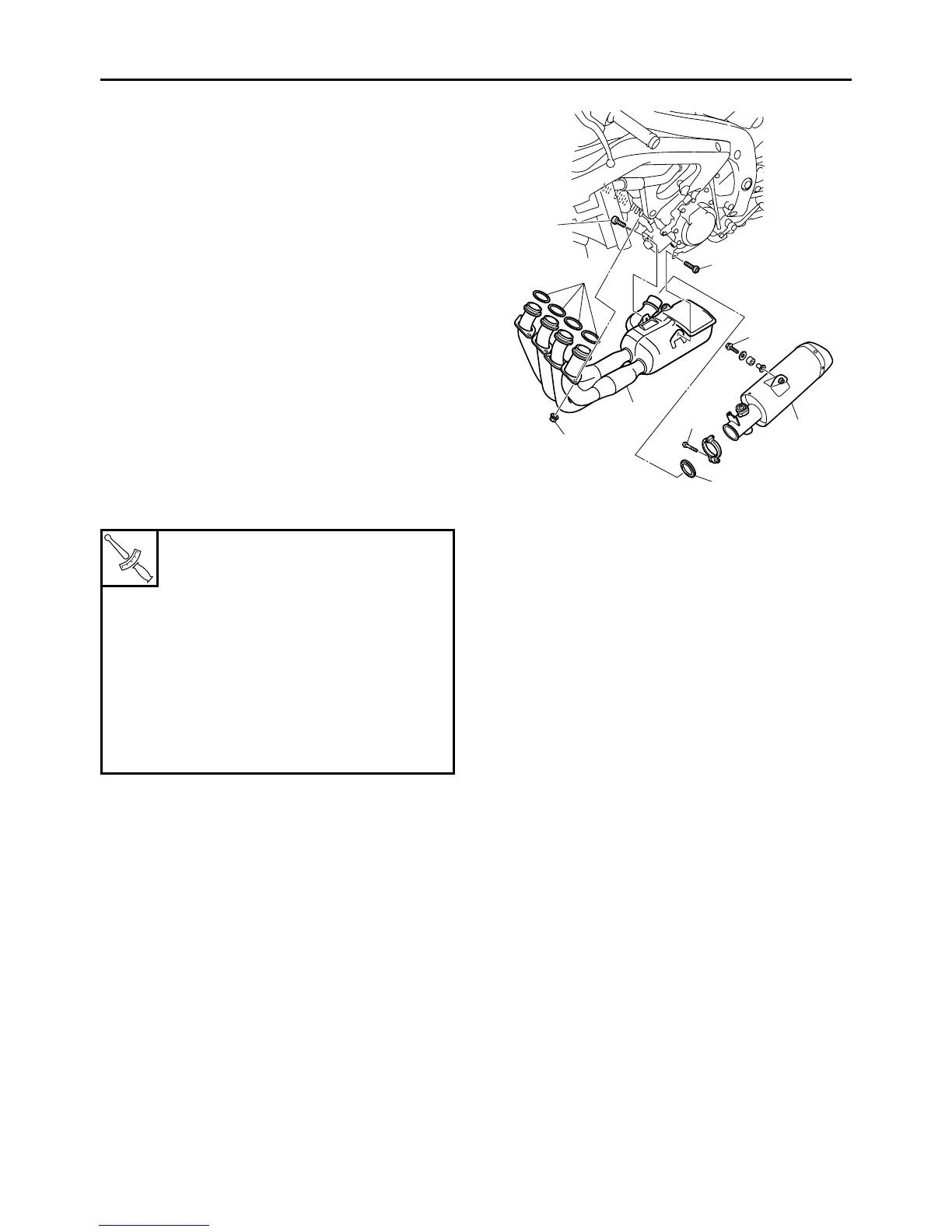

CHECKING THE EXHAUST SYSTEM

The following procedure applies to all of the ex-

haust pipe assembly and gaskets.

1. Remove:

• Side cowlings

• Bottom cowlings

Refer to “GENERAL CHASSIS” on page 4-1.

2. Check:

• Exhaust pipe assembly “1”

• Muffler “2”

Cracks/damage → Replace.

• Gaskets “3”

Exhaust gas leaks → Replace.

3. Check:

Tightening torque

• Exhaust pipe assembly and cylinder head

nuts “4”

• Exhaust pipe assembly and exhaust pipe as-

sembly bracket bolts “5”

• Exhaust pipe assembly and muffler bolt “6”

• Muffler and right rider footrest bracket bolt “7”

4. Install:

• Bottom cowlings

• Side cowlings

Refer to “GENERAL CHASSIS” on page 4-1.

EAS21090

CHECKING THE CANISTER (for California

only)

1. Remove:

• Fuel tank

Refer to “FUEL TANK” on page 7-1.

• Air filter case

Refer to “AIR FILTER CASE” on page 7-5.

2. Check:

• Canister

• Canister purge hoses

• 3-way joint

• Fuel tank breather hose (rollover valve to

canister)

Cracks/damage → Replace.

Refer to “THROTTLE BODIES” on page 7-8.

3. Install:

• Air filter case

Refer to “AIR FILTER CASE” on page 7-5.

• Fuel tank

Refer to “FUEL TANK” on page 7-1.

EAS21100

ADJUSTING THE EXUP CABLES

1. Remove:

• EXUP valve pulley cover “1”

T

R

.

.

Exhaust pipe assembly and cylin-

der head nut

20 Nm (2.0 m·kg, 14 ft·lb)

Exhaust pipe assembly and ex-

haust pipe assembly bracket bolt

20 Nm (2.0 m·kg, 14 ft·lb)

Exhaust pipe assembly and muf-

fler bolt

10 Nm (1.0 m·kg, 7.2 ft·lb)

Muffler and right rider footrest

bracket bolt

20 Nm (2.0 m·kg, 14 ft·lb)

2

3

1

(8)

3

7

6

4

5

5

Loading...

Loading...