CONNECTING RODS AND PISTONS

5-62

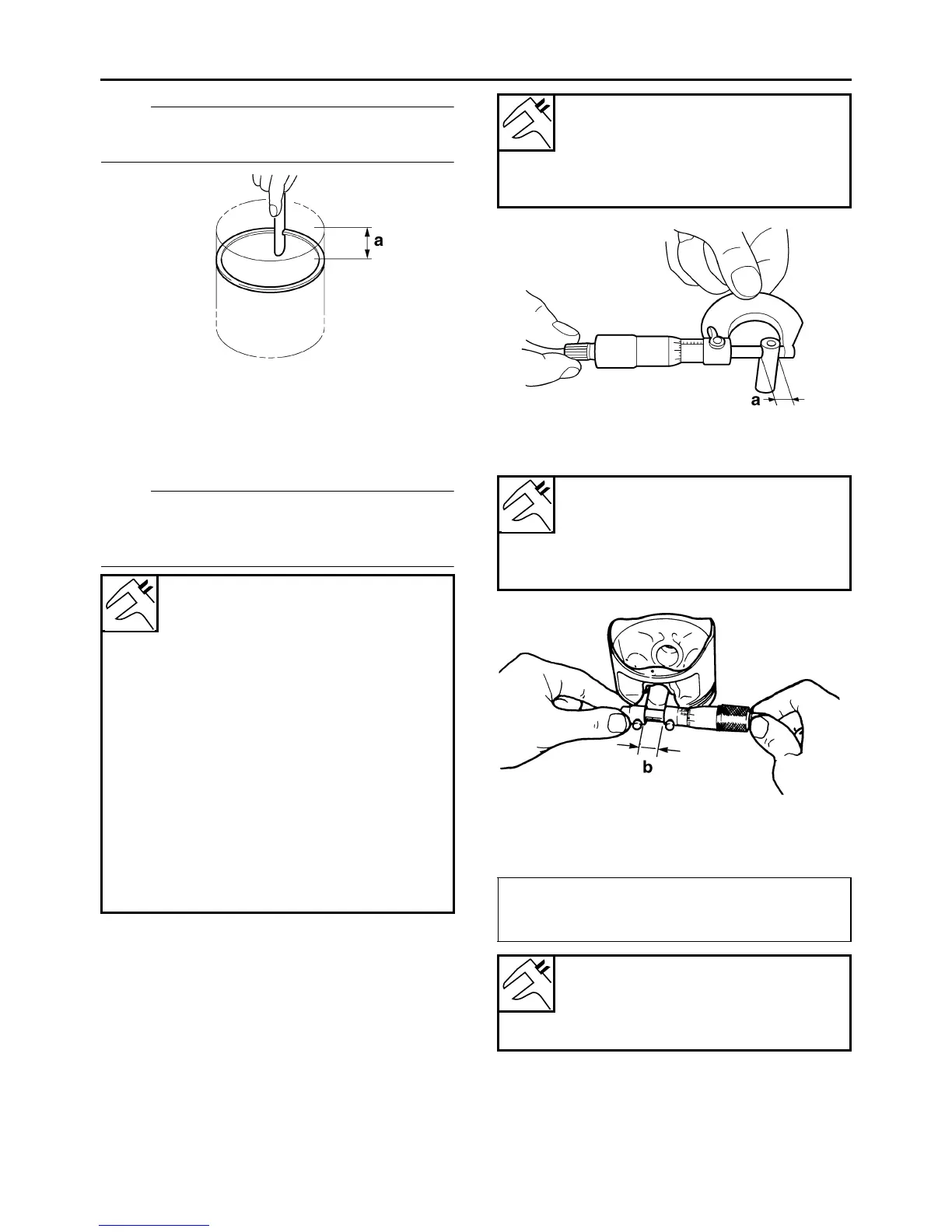

NOTE:

Level the piston ring into the cylinder with the

piston crown.

3. Measure:

• Piston ring end gap

Out of specification → Replace the piston

ring.

NOTE:

The oil ring expander spacer’s end gap cannot

be measured. If the oil ring rail’s gap is exces-

sive, replace all three piston rings.

EAS24440

CHECKING THE PISTON PINS

The following procedure applies to all of the pis-

ton pins.

1. Check:

• Piston pin

Blue discoloration/grooves → Replace the

piston pin and then check the lubrication sys-

tem.

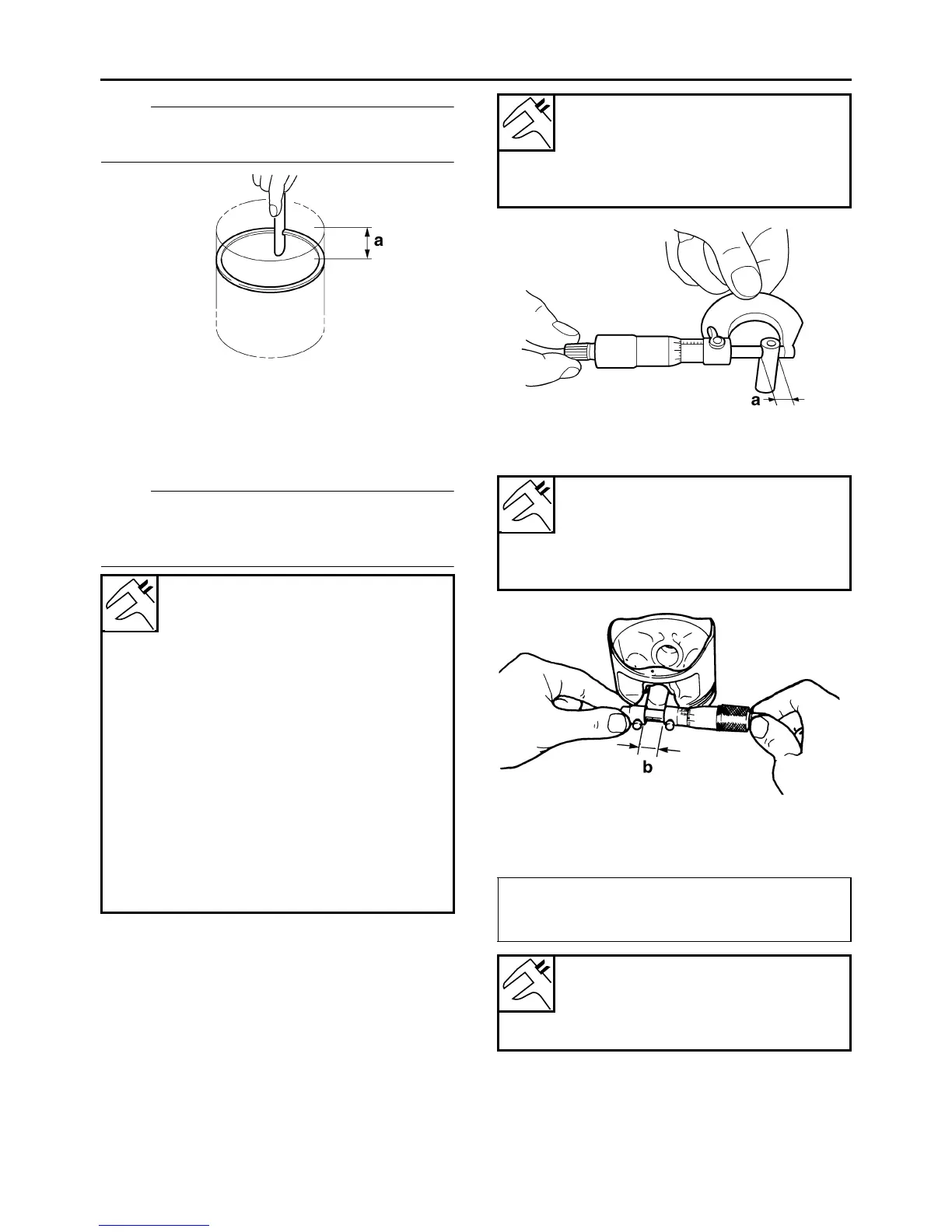

2. Measure:

• Piston pin outside diameter “a”

Out of specification → Replace the piston pin.

3. Measure:

• Piston pin bore diameter “b”

Out of specification → Replace the piston.

4. Calculate:

• Piston-pin-to-piston-pin-bore clearance

Out of specification → Replace the piston pin

and piston as a set.

a. 5 mm (0.20 in)

Piston ring

Top ring

End gap (installed)

0.25–0.35 mm (0.0098–0.0138

in)

Limit

0.55 mm (0.0217 in)

2nd ring

End gap (installed)

0.70–0.80 mm (0.0276–0.0315

in)

Limit

1.00 mm (0.0394 in)

Oil ring

End gap (installed)

0.10–0.35 mm (0.0039–0.0138

in)

Piston pin outside diameter

14.991–15.000 mm (0.5902–

0.5906 in)

Limit

14.971 mm (0.5894 in)

Piston pin bore inside diameter

15.002–15.013 mm (0.5906–

0.5911 in)

Limit

15.043 mm (0.5922 in)

• Piston-pin-to-piston-pin-bore clearance =

Piston pin bore diameter “b” -

Piston pin outside diameter “a”

Piston-pin-to-piston-pin-bore

clearance

0.002–0.022 mm (0.00007–

0.00068 in)

Loading...

Loading...