STwrench User Guide STwrench Settings

9836 4134 01 Edition 2.9 185 (326)

In general, when defining the coefficients in the Pset parameters, leave the Torque Correction Coefficient

set to 1, and the Angle Correction Coefficient set to 0, in the RFID TAG of the end-fitting tool; if

different values are specified, the STwrench corrects torque and angle reading considering all of them (the

two torque correction coefficients are multiplied, while the two angle correction coefficients are added

together).

Warning: The torque correction coefficient alters the STwrench torque measurement; a wrong

value of this coefficient may cause an improper torque reading, leading to the risk of executing

a tightening at a different target torque compared to what is expected. Ensure the proper value is

calculated when a wrench extension is used. For end-fitting tools used without wrench

extensions, the torque correction coefficient must be left set to 1.

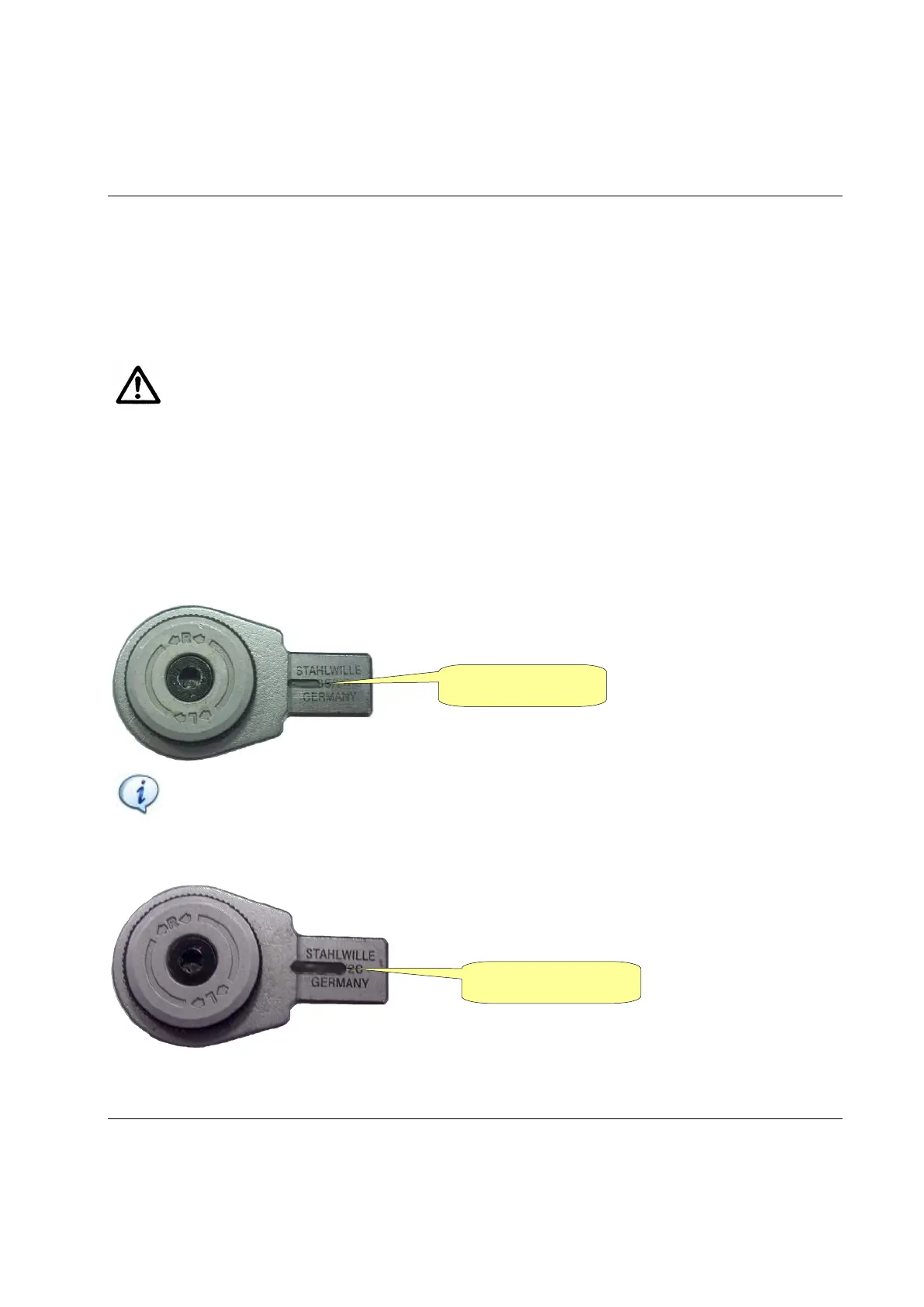

10.3.2.4 Compatibility between different end-fitting tools

Only the following type of end-fitting tool is supported by the STwrench:

NOTE: If this tool is already used by the LINEwrench, it will not be read by the STwrench.

However, once it has been written with the TAG writer function, it can be read and used by the

STwrench; when this is done the tool will no longer work with the LINEwrench.

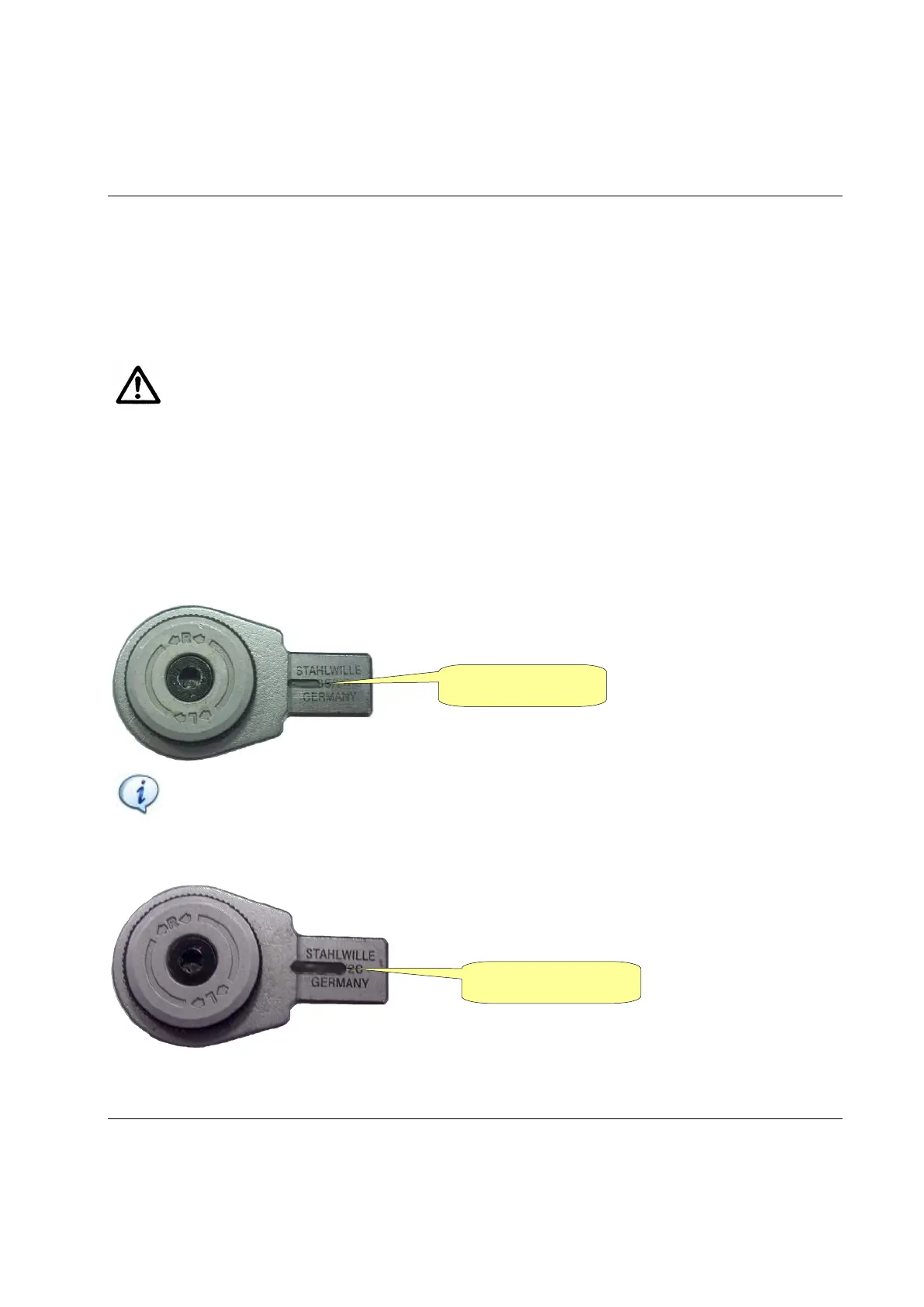

It is not possible to use old end-fitting tools designed for the LINEwrench:

Long RFID TAG

Loading...

Loading...