Appendix A – Calculating correction coefficients for extensions STwrench User Guide

310 (326) 9836 4134 01 Edition 2.9

22 Appendix A – Calculating Torque and

Angle Correction Coefficients

When the joint design or space limitations preclude use of standard sockets or tools, it may be necessary to

use special extension spanners to fit the application.

In these cases, the wrench measure must be adequately compensated because the factory calibration is

made for the standard arm (L) and the extension arm (E) increases the measured torque. The angle

measure is also affected by the extensions, due to its specific torsion when the torque is applied.

Also when a torque multiplier is used on the STwrench, the torque provided on the joint is greater than the

torque produced by the wrench; in this case the torque correction coefficient is needed to adjust the

STwrench torque reading (see below). The angle measurement is also affected, but in this case the

STwrench cannot compensate the angle measurement.

22.1 Torque Correction Coefficient

From the relation between the displayed and applied torque

, the torque correction

coefficient is given by the following formula:

Torque correction coefficient =

D = displayed torque

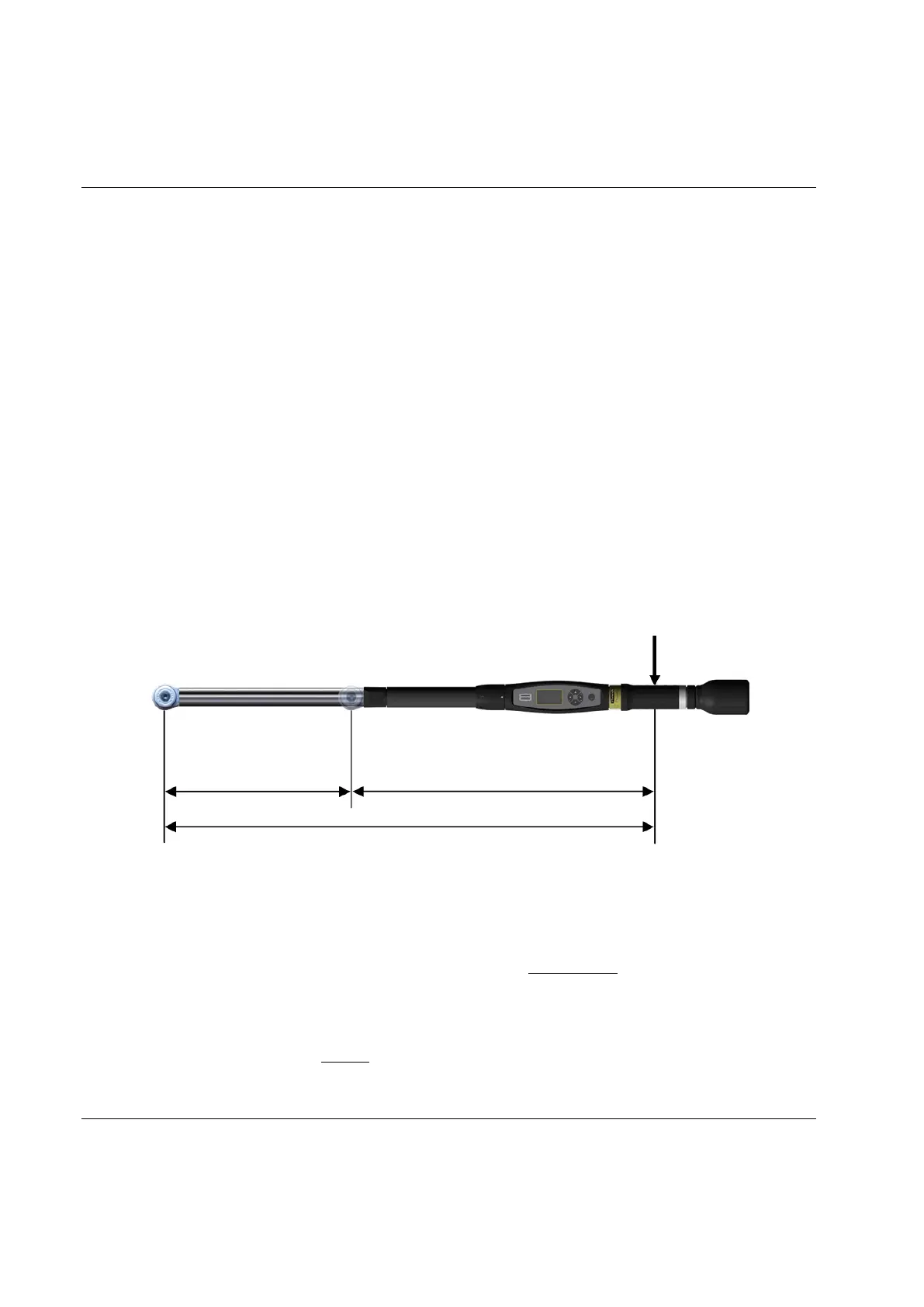

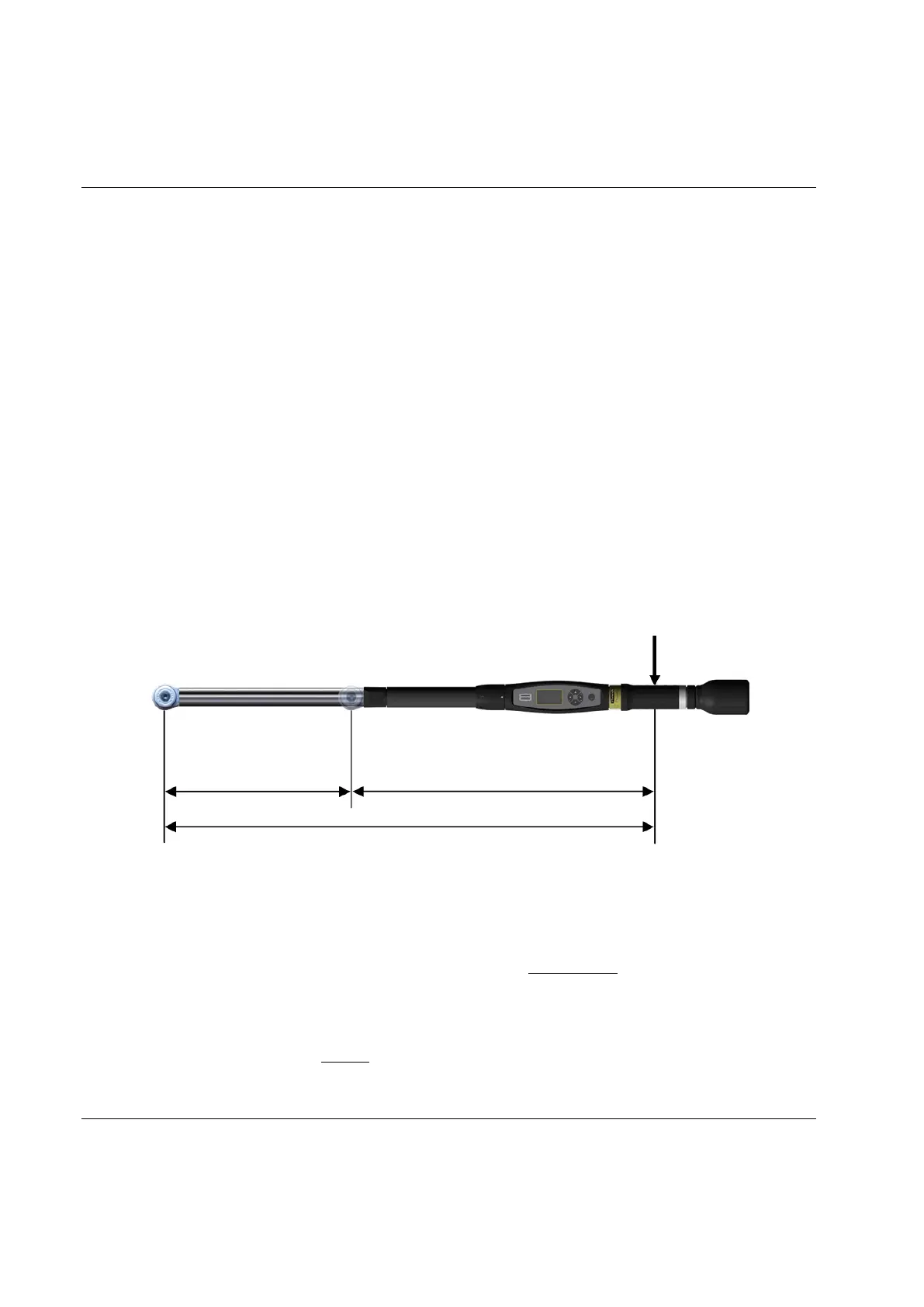

L = standard arm (see the Specifications chapter for details)

E = extension arm

L + E = total arm

Loading...

Loading...