Appendix A – Calculating correction coefficients for extensions STwrench User Guide

314 (326) 9836 4134 01 Edition 2.9

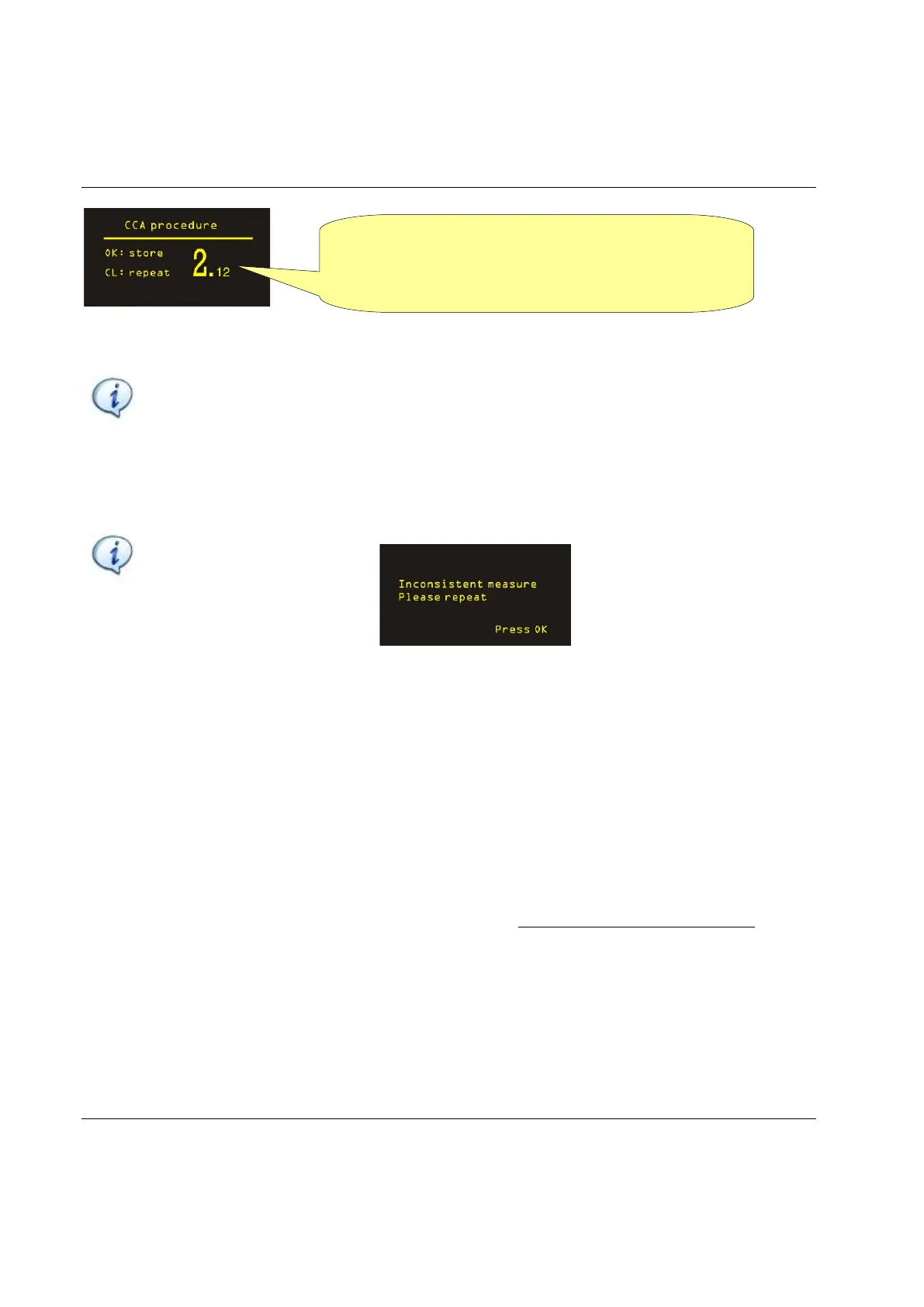

Click on OK on the wrench keyboard to store the Torque and Angle Correction Coefficient in the RFID

TAG of the extension. Click on CL to repeat the three tests.

NOTE: An Angle Correction Coefficient with a value lower than 1 degree is not considered

relevant, and the value stored is zero.

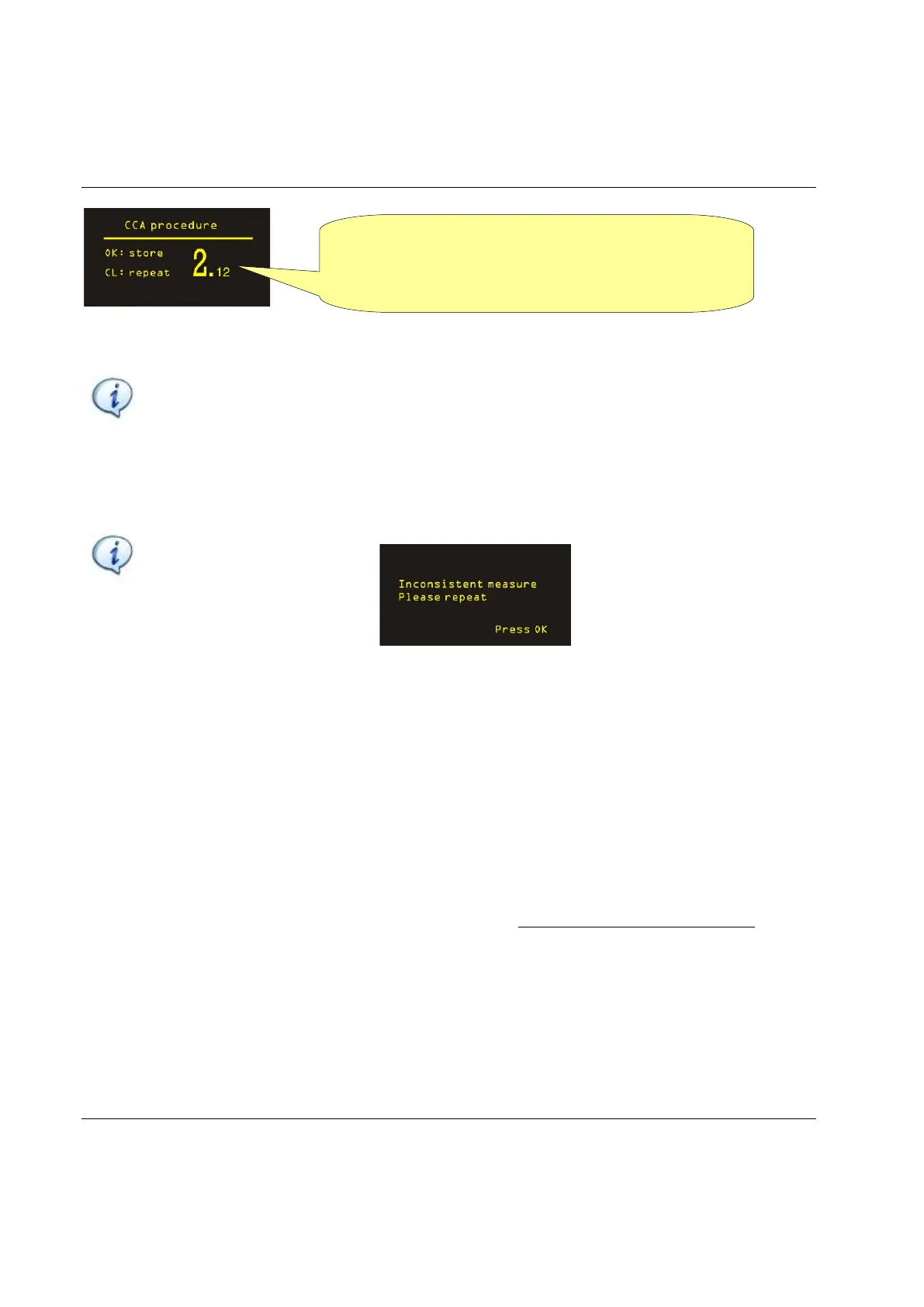

NOTE: If the difference between maximum and minimum angle results of the three tests is

greater than 10% of the maximum values, the results are not considered consistent, and the

procedure must be repeated. The following message is displayed:

22.3 Correction Formulas

During the tightening, the torque and angle measured by the transducers are corrected to obtain the real

torque and angle values, which are displayed on the wrench and used in the tightening traces and results.

The correction formulas are:

StartCyclecapacityWrench

StartCyclemeasuredTorque

tCoefficienAnglemeasuredAngledisplayedAngle

−

−

×−=

tcoefficienTorquemeasuredTorquedisplayedTorque ×=

The angle value displayed here is the value referred to

at wrench capacity. In this example, 2.12 degrees at

wrench capacity is equivalent to 1.59 degrees at 75%

capacity.

Loading...

Loading...