10-17

HRX217HYA • HRX217HZA CAM PULLEY/CRANKSHAFT/ PISTON/CYLINDER

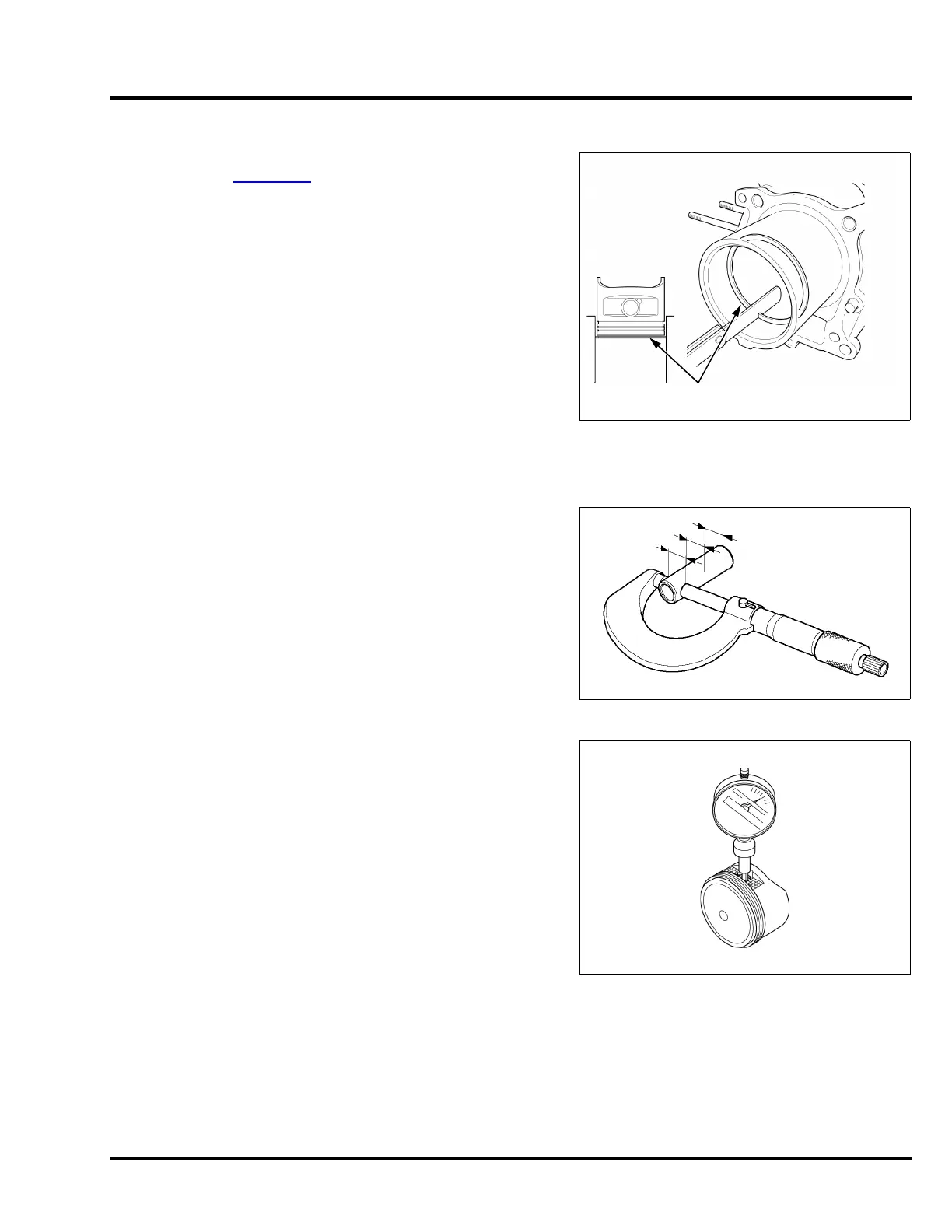

PISTON RING END GAP

Before inspection, check whether the cylinder sleeve I.D. is within

the specification (page 10-15

).

Put the piston ring in the cylinder and then use the piston crown to

push the ring down.

This will make the piston ring horizontal so ring end gap can be

measured.

Measure each piston ring [1] end gap using a feeler gauge.

If any of the measurements is more than the service limit, replace

the piston rings (top, second, oil) as a set.

Do not hone the cylinder.

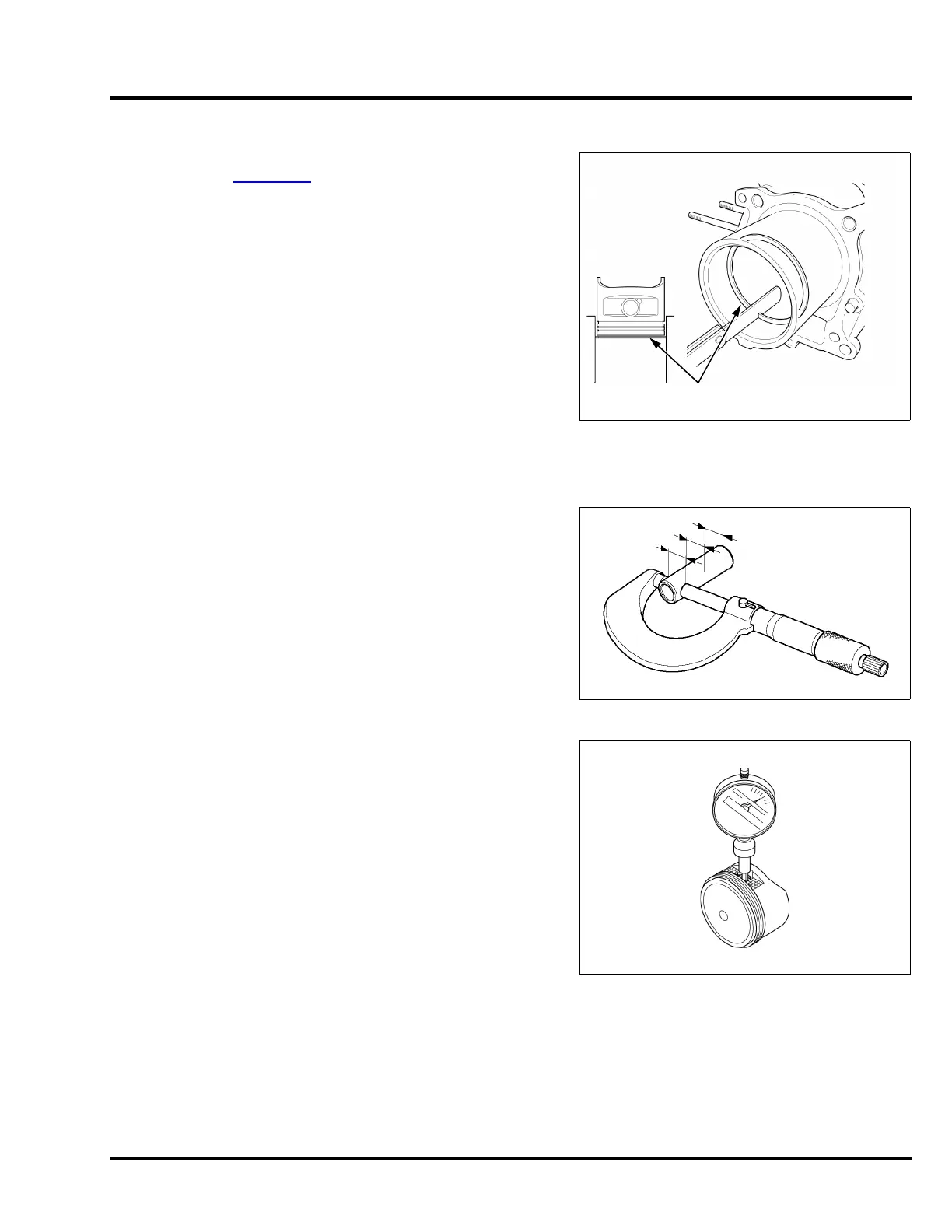

PISTON PIN O.D.

Measure and record the piston pin O.D. at three points (both ends

and middle). Take the minimum reading to determine piston pin

O.D.

If the measurement is less than the service limit, replace the piston

pin.

PISTON PIN BORE I.D.

Measure and record the piston pin bore I.D. of the piston.

If the measurement is more than the service limit, replace the

piston.

PISTON PIN-TO-PISTON PIN BORE CLEARANCE

Subtract the piston pin O.D. from the piston pin bore I.D. to obtain

the piston pin-to-piston pin bore clearance.

If the calculated clearance is more than the service limit, replace

the piston pin and recheck the clearance.

If the clearance is still more than the service limit with the new

piston pin, replace the piston.

STANDARD:

Top: 0.20 – 0.30 mm (0.008 – 0.012 in)

Second: 0.30 – 0.40 mm (0.012 – 0.016 in)

Oil (side rail): 0.20 – 0.45 mm (0.008 – 0.018 in)

SERVICE LIMIT:

Top/Second/oil: 1.0 mm (0.04 in)

STANDARD: 12.994 – 13.000 mm (0.5116 – 0.5118 in)

SERVICE LIMIT: 12.954 mm (0.5100 in)

STANDARD: 13.002 – 13.016 mm (0.5119 – 0.5124 in)

SERVICE LIMIT: 13.048 mm (0.5137 in)

STANDARD: 0.002 – 0.020 mm (0.0001 – 0.0008 in)

SERVICE LIMIT: 0.070 mm (0.0028 in)

Loading...

Loading...