10-23

HRX217HYA • HRX217HZA CAM PULLEY/CRANKSHAFT/ PISTON/CYLINDER

VALVE SEAT RECONDITIONING

Thoroughly clean the combustion chamber and valve seats to

remove carbon deposits (P. 3 - 1 0

).

Apply a light coat of Prussian Blue or erasable felt-tipped marker

ink to the valve seat.

Insert the valve, and snap it closed against its seat several times.

Be sure the valve does not rotate on the seat. The transferred

marking compound will show any area of the seat that is not

concentric.

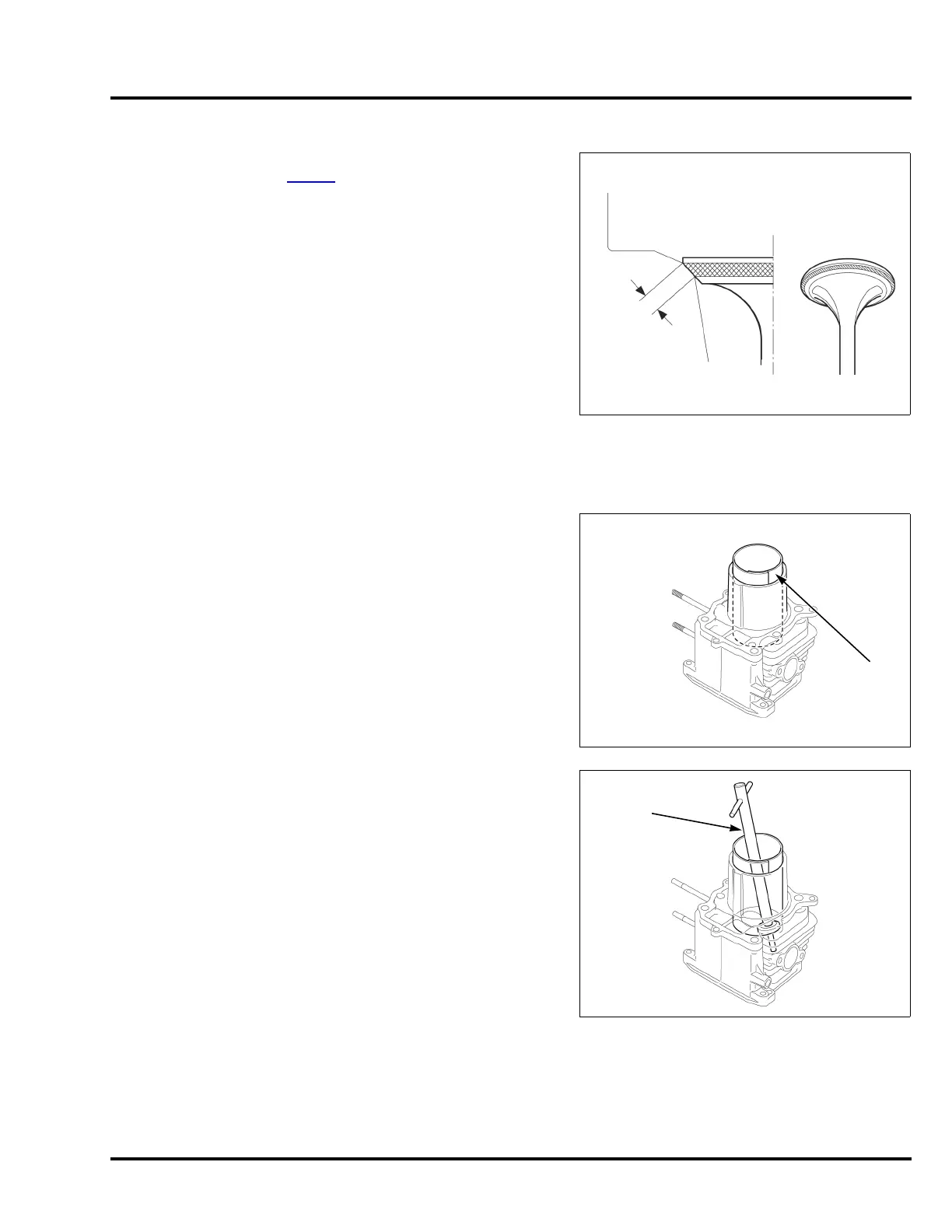

Measure the valve seat width of the cylinder head.

If the measurement is more than the service limit, recondition the

valve seat.

Check whether the valve seat contact area of the valve is too high.

If the valve seat is too high, recondition the valve seat.

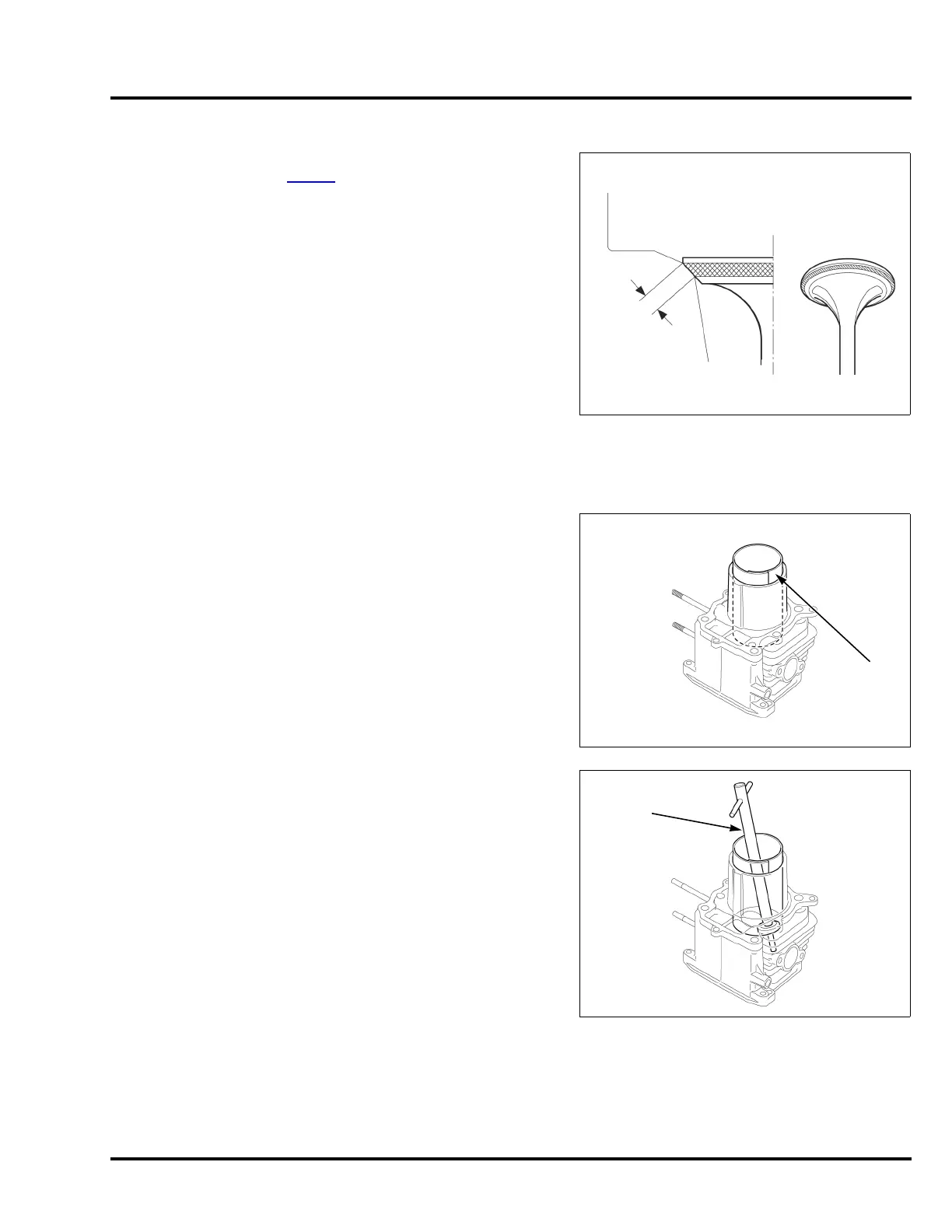

Prepare a thick paper cylinder or equivalent material with a large

enough diameter to fit against the cylinder wall of the cylinder.

Insert the thick paper into the cylinder to protect the cylinder wall

during valve seat reconditioning.

Valve seat cutters/grinder or equivalent valve seat re-facing

equipment is recommended to correct a worn valve seat.

Turn the cutter clockwise, never counterclockwise. Continue to

turn the cutter as you lift it from the valve seat.

STANDARD: 0.7 – 0.9 mm (0.03 – 0.04 in)

SERVICE LIMIT: 1.8 mm (0.07 in)

VALVE SEAT

WIDTH

VALVE SEAT

TOO HIGH

Loading...

Loading...